Tester of simulating weighing sensor weighing precision

A technology of weighing sensor and weighing accuracy, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of prolonged operation time, inconvenient operation, affecting the fairness of trade measurement, etc., and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

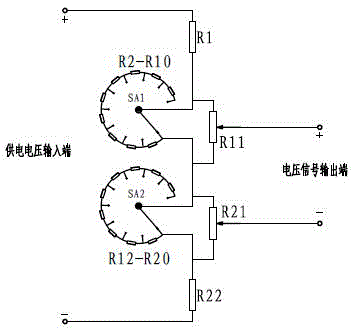

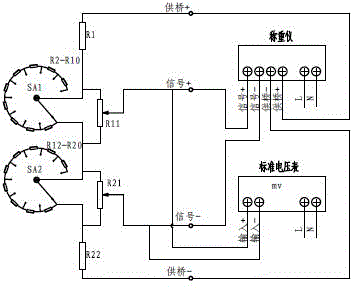

[0021] Depend on Figure 1-2 It can be seen from the illustrated embodiment that the output voltage adjustment circuit is included, and the output voltage adjustment circuit is divided into a voltage fine adjustment circuit and a voltage coarse adjustment circuit. The structure of the circuit is the same as that of the voltage coarse adjustment circuit: the resistance box and the potentiometer are connected in parallel; the resistance value ratio of each resistance box in the voltage fine adjustment circuit and the voltage coarse adjustment circuit is 1:5~20; the center tap of the two potentiometers is Voltage signal output terminal.

[0022] The resistance ratio of the resistance box SA2 in the voltage fine adjustment circuit and the resistance box SA1 in the voltage coarse adjustment circuit is 1:10; the nominal resistance of the potentiometer R21 in the voltage fine adjustment circuit and the potentiometer R11 in the voltage coarse adjustment circuit are the same .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com