10kv live-line work insulating support rod

A live working, 1.10KV technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of poor reliability of line spacing control, time-consuming and labor-intensive, accident-prone, etc., to save manpower and time, and ensure operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

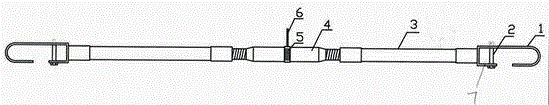

[0007] The embodiments are described in detail with reference to the accompanying drawings. In the present invention, an insulated support rod 3 is screwed on both ends of an insulated lead screw 4, a ratchet 5 is fixed in the middle of the insulated lead screw, and an operating handle 6 is provided on the ratchet. , A wire hook 1 is fixed at the outer ends of the two insulating struts, and a U-shaped groove 7 is set at the fixed end of each wire hook and the hook head. A line blocking pin 2 is installed respectively. When in use, the operator puts the wires on both sides into the hooks of the two insulated support rods, and rotates the handle to adjust the support rods so that there is enough safe distance between the wires on both sides to perform operations. It has the advantages of saving manpower, safety and reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com