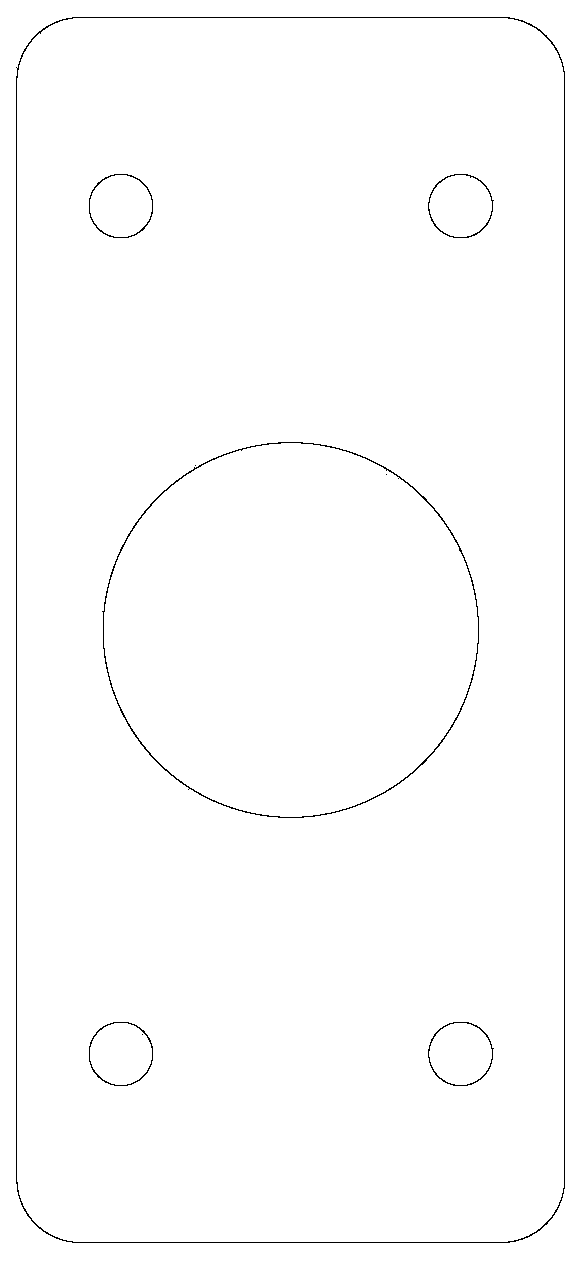

Continuous die structure for square washers

A washer and square technology, applied in the field of square washer continuous mold structure, can solve the problems of increasing the difficulty of unloading, difficult product output, product bending deformation, etc., to achieve the effect of reducing difficulty, difficult bending deformation, and convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

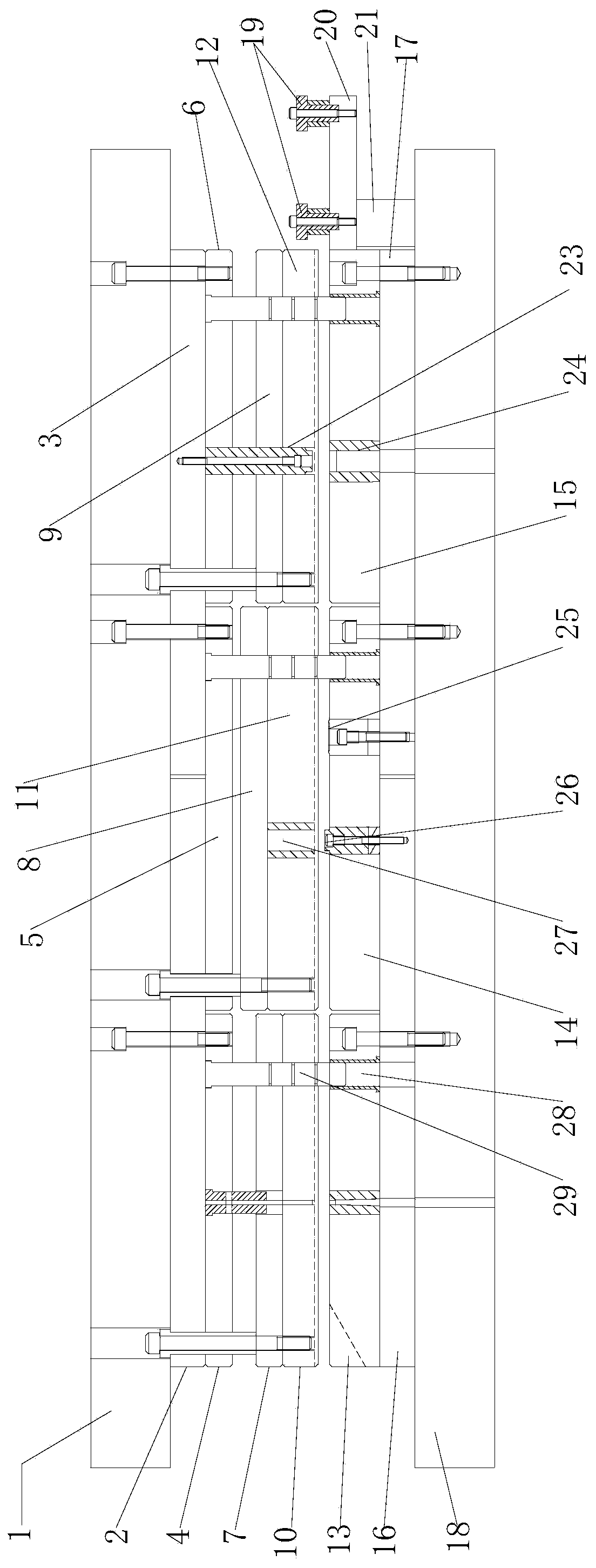

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

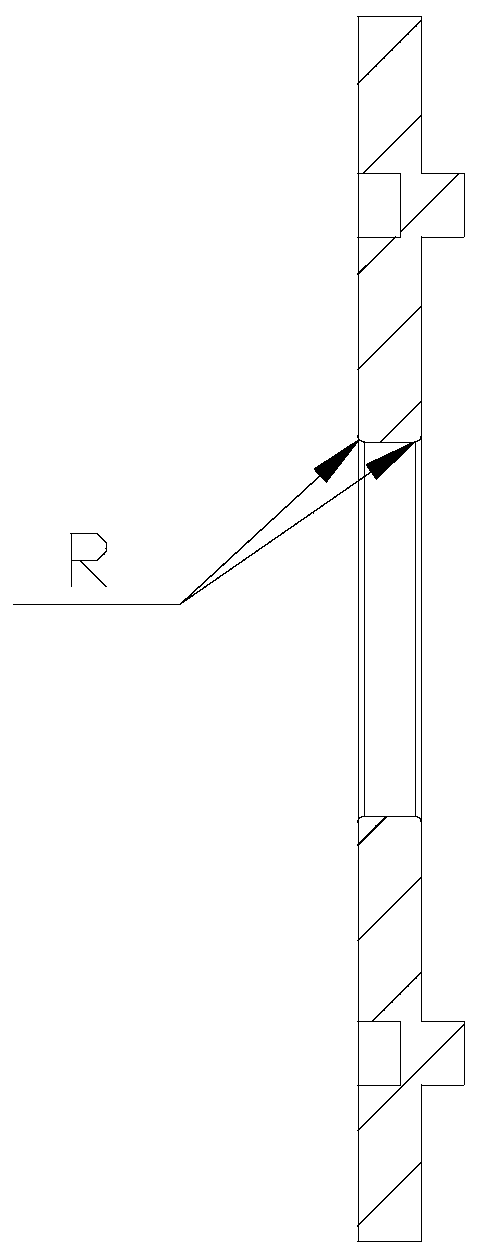

[0022] exist Figure 4 In the process of producing square washer with the continuous die shown, the steps are generally divided into the following points: S1 is the step of cutting the blank to produce rough positioning and eliminate the inconsistency of the width of the slitting coil; S2 is to pre-set the blank. The step of punching the guide hole for precise positioning of the strip; S3 the step of fine-punching the center hole on the blank; S4 the step of pre-pressing the corner of the center hole on the blank; S5 the step of pressing the corners on both sides of the center hole on the blank; S6 The step of punching the blank; S7 the step of polishing the center hole of the blank; S8 the step of cutting the edge of the blank to form a square washer product; S9 the step of separating the square washer product, the key of which is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com