A device for printing number marks on a cylindrical metal surface and its application method

A metal surface and cylindrical technology, applied in the field of machinery, can solve the problems of public reports of unused conditions, unseen patented technologies and public reports of literature, etc., and achieve the goals of reduced fatigue impact, low cost, and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Print number 6 on the surface of cylindrical metal 3:

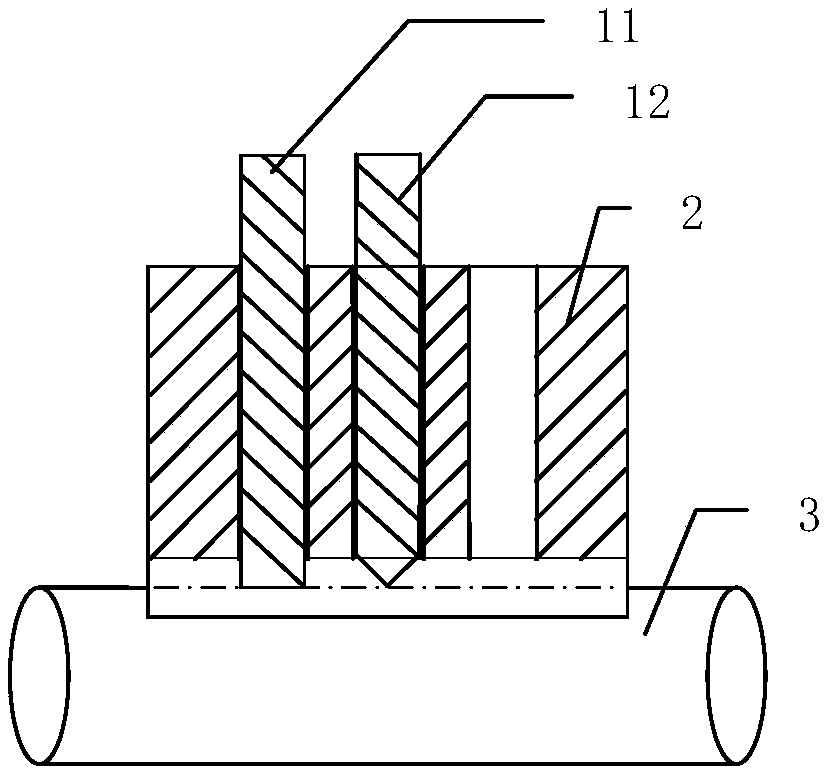

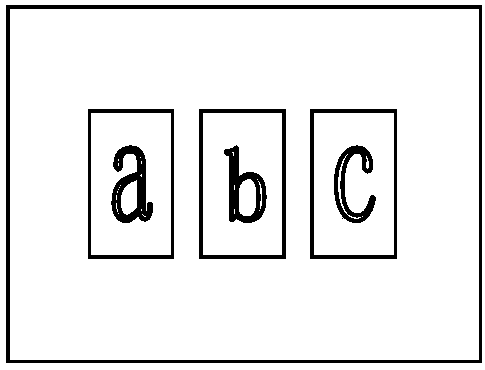

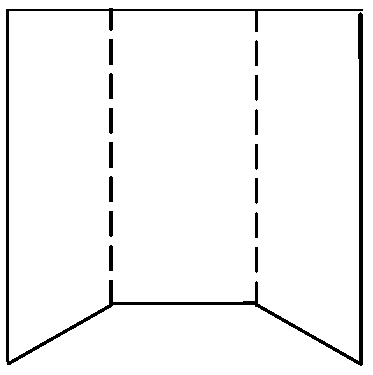

[0028] According to the number 6 to be printed, the 1-digit number does not need to be split. Refer to the comparison diagram of the print orientation code and the number. The print orientation mark code graphic corresponding to the number 6 is Select a dot type prefix 12 at the a and b through holes of the fixed bracket 2, and select a straight type prefix 11 at the c through hole position to prepare for dotting, and then place the metal fixed bracket 2 on the cylindrical metal 3 parallel to the axis. On the surface, insert the heads of the corresponding metal prefixes 11 / and 12 downwards into the through holes at the above-mentioned three corresponding positions selected on the metal fixing bracket 2, and tap the tails of the metal prefixes 11 / and 12 with a hand hammer , until the task is successfully completed. A set of clearly printed orientation mark codes corresponding to the number 6 will be left on the ...

Embodiment 2

[0030] Print the number 27 on the cylindrical metal surface:

[0031] According to the number 27 to be printed, 27 can be divided into numbers 2 and 7. Referring to the comparison chart of the print orientation code and the number, the print orientation mark code graphic corresponding to the number 2 is All select the dot type prefix 12 at the a, b through hole positions of the fixed bracket 2 to prepare for dotting; Select a dot type prefix 12 at the positions a and c of the fixing bracket, and select a straight type prefix 11 at the position b through hole to prepare for dotting, and then place the metal fixing bracket 2 parallel to the axis on the surface of the cylindrical metal 3 First, insert the heads of the corresponding metal prefixes 11 / and 12 downwards into the through holes at the above-mentioned corresponding positions selected on the metal fixing bracket 2, and tap the tails of the metal prefixes 11 / and 12 with a hand hammer. Between (such as between 2 and 7...

Embodiment 3

[0033] Print the number 308 on a cylindrical metal surface:

[0034] According to the number 308 to be printed, 308 can be divided into numbers 3, 0, and 8. Refer to the comparison chart of the print orientation code and the number. The print orientation mark code graphic corresponding to the number 3 is Select the dot type prefix 12 at the a through hole position of the fixed bracket 2, and select the one-word type prefix 11 at the b through hole position to prepare for dotting; the corresponding prefix of the number 0 prints the orientation mark coding pattern as Select the dot type prefix 12 at the a through hole position of the fixed bracket 2 to prepare for dotting; the corresponding digit 8 prints the orientation mark coding pattern as Select a dot type prefix 12 at the through hole position of the fixing bracket 2, and select a straight type prefix 11 at the positions of the b and c through holes to prepare for dotting, and then place the metal fixing bracket 2 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com