Upflow Adsorption Bed Reactor for Treating Nitrogen and Phosphorus Deficient Organic Chemical Wastewater

A technology of organic chemical industry and reactor, which is applied in the field of organic wastewater treatment to achieve the effect of low cost, high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

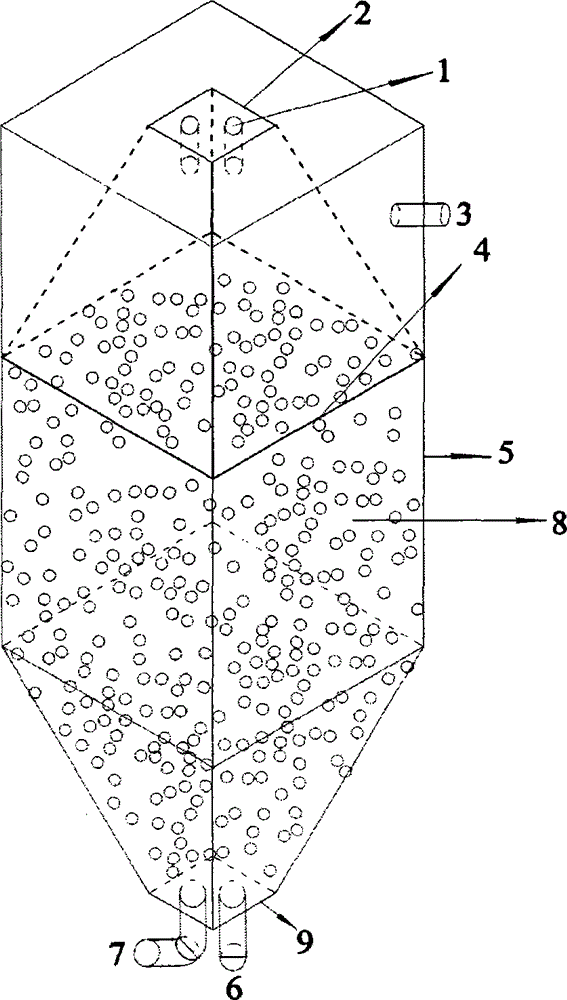

[0028] (1) The preparation process of the upflow adsorption bed reactor for treating nitrogen and phosphorus deficiency organic chemical wastewater is as follows:

[0029] The upflow adsorption bed reactor is mainly composed of plexiglass plate and stainless steel. The main body of the reactor is plexiglass plate, which is divided into two parts. The upper part is a cuboid with a length of 40cm, a width of 40cm, and a height of 60cm. Cone, upper bottom 40cm, lower bottom 10cm, waist length 30cm. The eluent inlet is a plastic circular tube with a diameter of 2.5 cm and a length of 8 cm. Its center line is located on a center line at the upper end of the reactor body on the lid of the adsorption tank, and the two inlets are located at 0.5 cm from the center point. The adsorbent inlet is a square with a side length of 10 cm, located at the center of the upper end of the reactor main body. The water outlet is a plastic round tube with a diameter of 3cm. The permeable baffle is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com