High-temperature high-pressure oblique stop valve

A high temperature and high pressure, globe valve technology, applied in the field of globe valves, can solve problems such as difficulty in meeting process requirements, difficulty in machining holes, etc., and achieve the effects of convenient assembly and maintenance, simple sealing and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

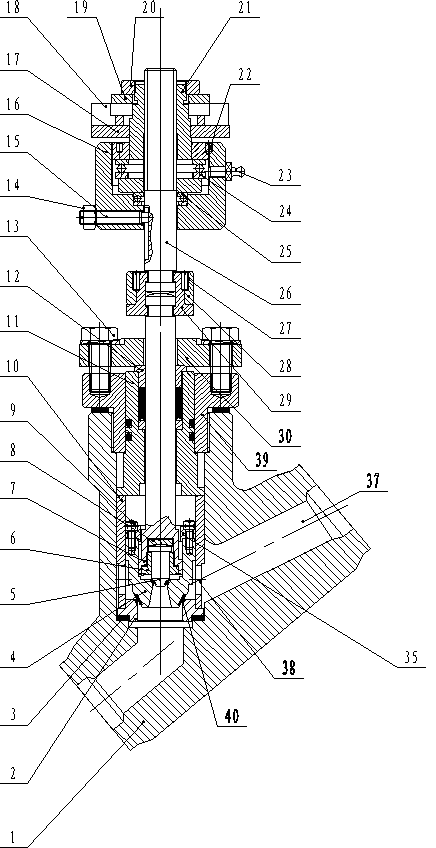

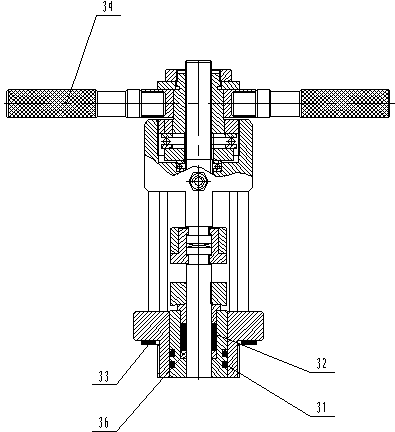

[0019] As shown in the figure, the high-temperature, high-pressure DC stop valve includes a handle 34, a worm 26, a worm nut 21 arranged at the top of the worm 26, a rotating assembly combined with the worm nut 21, a valve body 1, a stuffing culvert 11, The valve stem 7 connected with the worm 26 , the valve flap 4 and the valve seat 2 arranged in the valve body 1 .

[0020] Wherein, a ballast 10 is fixed above the valve seat 2 , and a gasket 3 is provided on the sealing contact surface between the bottom of the valve seat 2 and the valve body 1 . The steady flow sleeve 10 is provided with throttling and steady flow holes 38 corresponding to the medium channel 37 of the valve body 1 , and the throttling and steady flow holes 38 are located on the circumference of the steady flow sleeve 10 , and the number is four. The stuffing culvert 11 is placed on the top of the steady flow sleeve 10, a bracket 39 is installed between the stuffing culvert 11 and the valve body 1, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com