Separable electric connector capable of electrically connecting shells

A technology of electrical connectors and electrical conduction, which is applied in the direction of connection, parts of connection devices, protective grounding/shielding devices of connection parts, etc., can solve the problems of inability to use separate connectors, high processing costs, and complex product structures, and achieve Good versatility and promotion and application value, high reliability, and compact product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

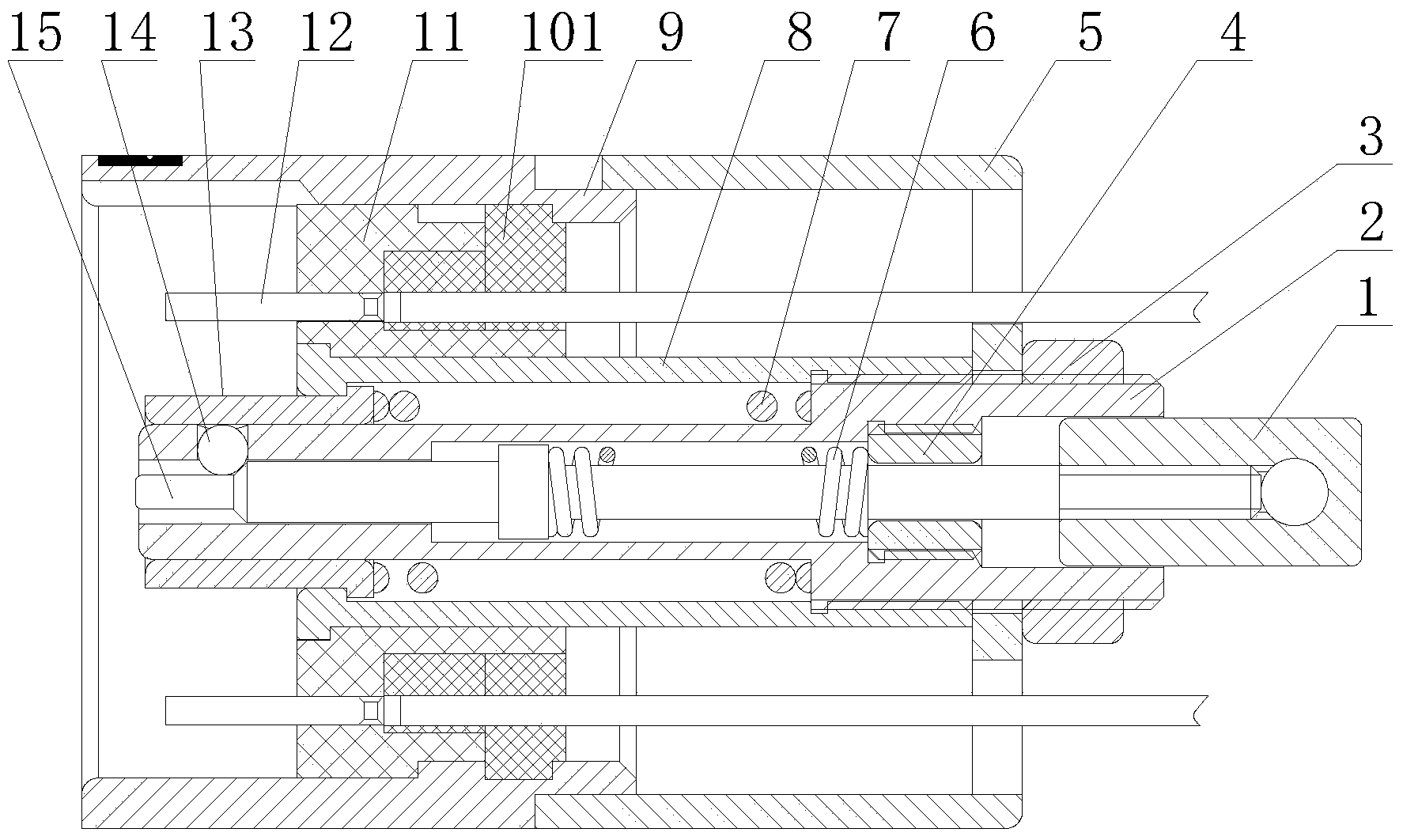

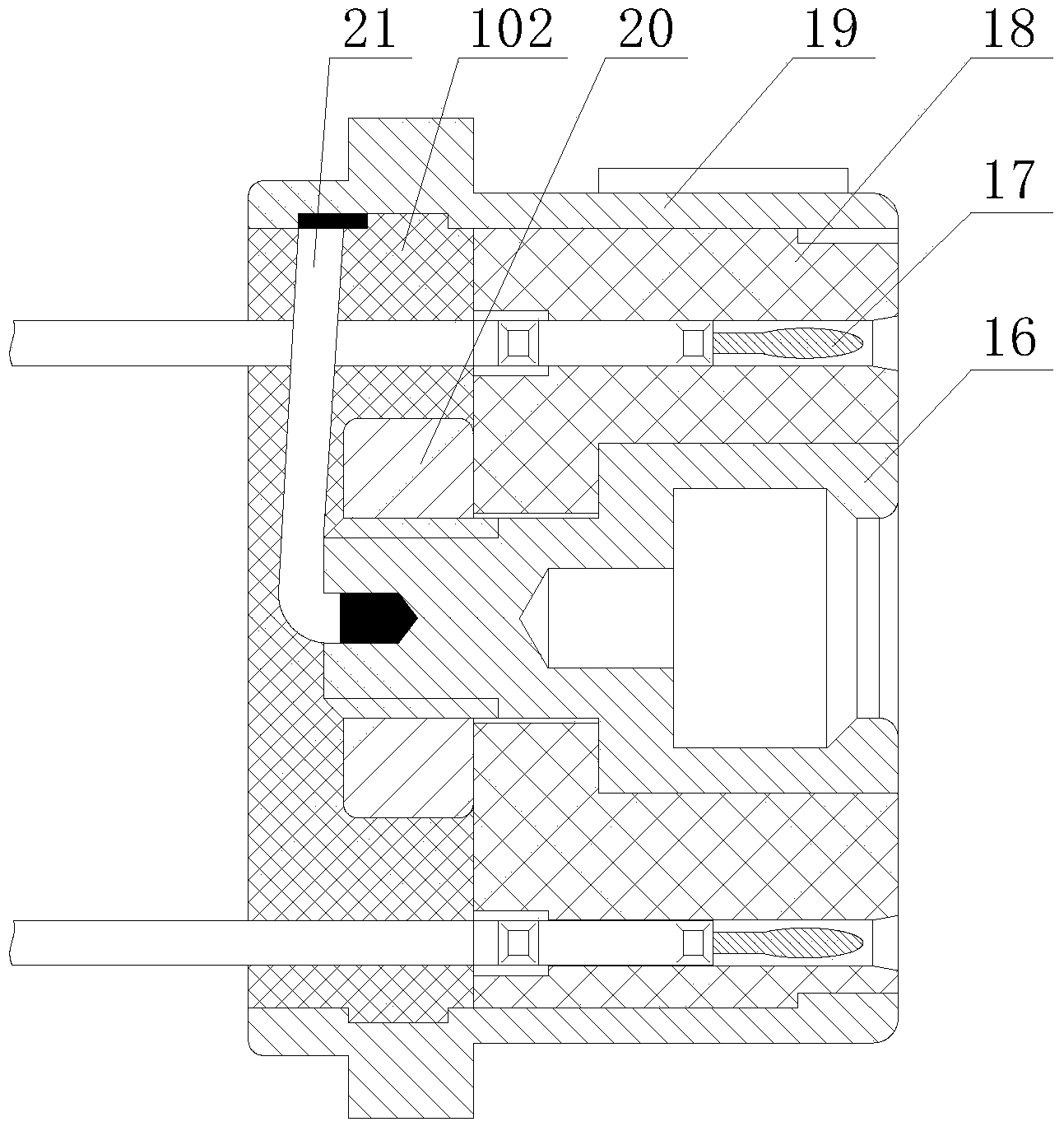

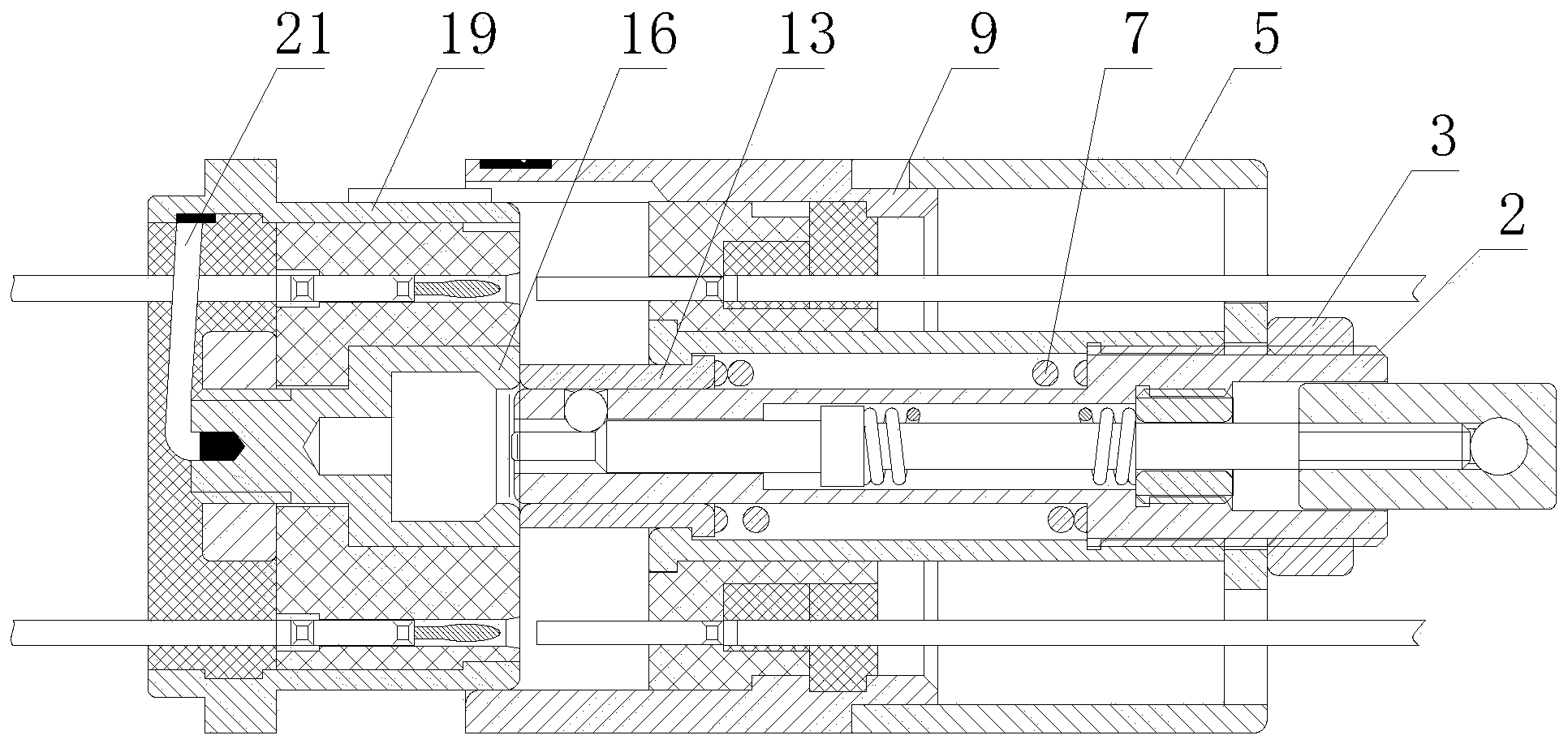

[0022] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0023] Such as Figure 1 to Figure 4 As shown, a shell electrical conduction separation electrical connector according to the present invention includes a plug and a socket. The plug is a free end, mainly composed of a plug assembly and a locking mechanism installed in the plug assembly. The socket is The fixed end is mainly composed of a seat shell 19 and a needle base 18 placed in the seat shell 19. A locking sleeve 16 is arranged in the needle base 18, and the tail end of the locking sleeve 16 connects with the needle base 18 through the nut B20. Fixed, a pin 17 is installed in the needle base 18 , and the base shell 19 is connected with the locking sleeve 16 through a wire 21 . The electrical conduction function is realized by connecting the socket housing 19 and the locking sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com