Manufacturing process of propeller and large efficient blade propeller of fan

A fan blade and manufacturing process technology, which is applied in the field of propeller and large-scale high-efficiency fan blade manufacturing technology, can solve the problems that foam cannot provide enough support, complex molding methods, poor structural tightness, etc., and achieve light weight, high yield, and internal good tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

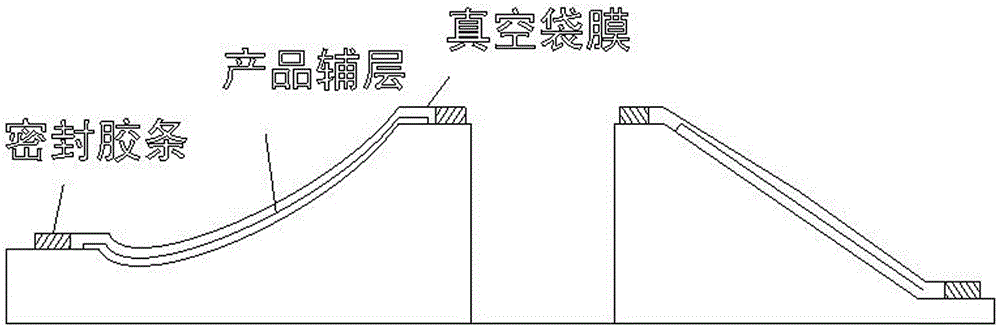

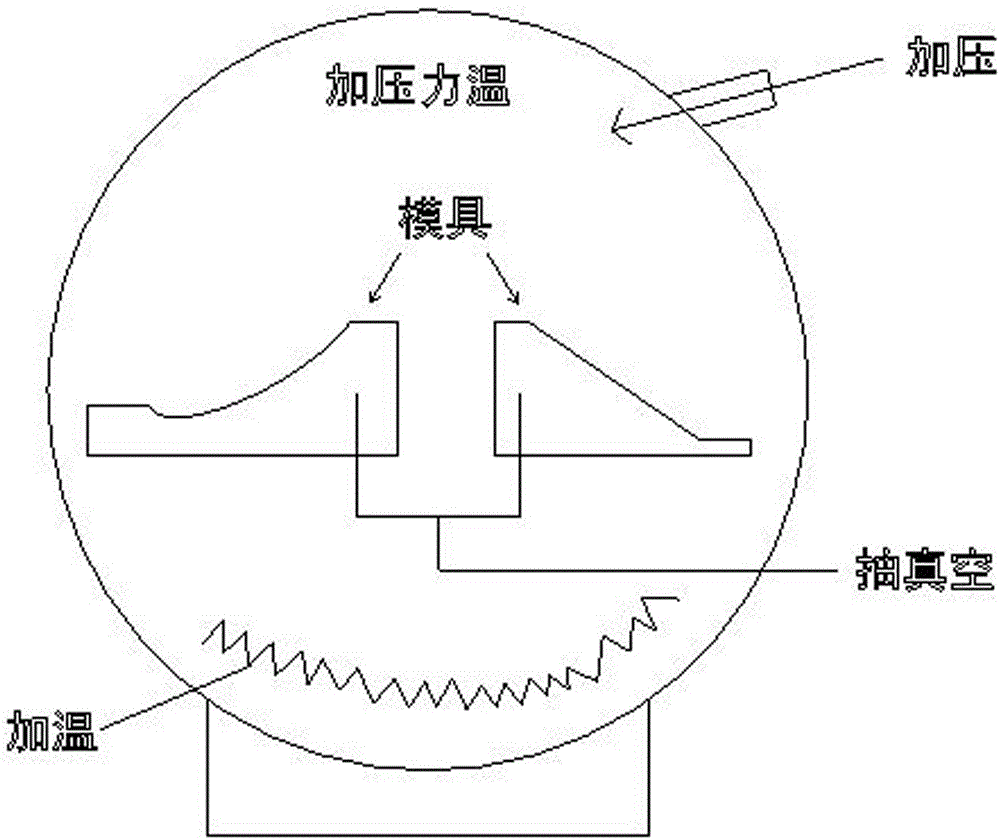

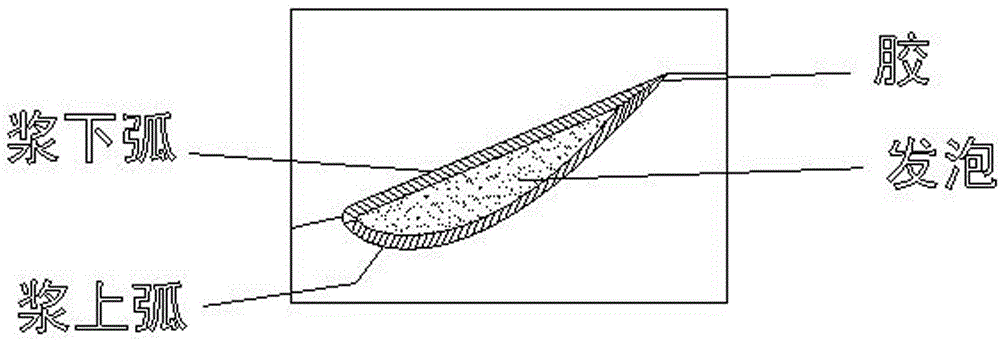

[0029] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0030] according to Figure 5 , 6 As shown, the manufacturing process of propellers and large high-efficiency fan blades adopts the hollow pressurization method: it is a new method of pressurizing the inside of the mold outward, which can obtain extremely high air pressure, up to 30 standard atmospheric pressure.

[0031] (The concept of pre-invasion material; it is the raw material for pre-invading epoxy resin on the reinforcing fibers in composite materials with precision pre-invasion equipment.)

[0032] Prepare the necessary outer mold for making oars, as well as the prefabricated polystyrene foam board. It is made to support the soft air bag and facilitate the laying of pre-invasion materials;

[0033] On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com