Displacement cutting type sharp device separation recoverer

A separation, recovery and cutting technology, applied in the field of medical devices, can solve the problems of heavy workload of nurses, increase of intermediate links in handling sharps, and low compliance of sharps boxes, so as to prevent needlestick injuries, facilitate operation, eliminate The effect of the risk of contracting a blood-borne infectious disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

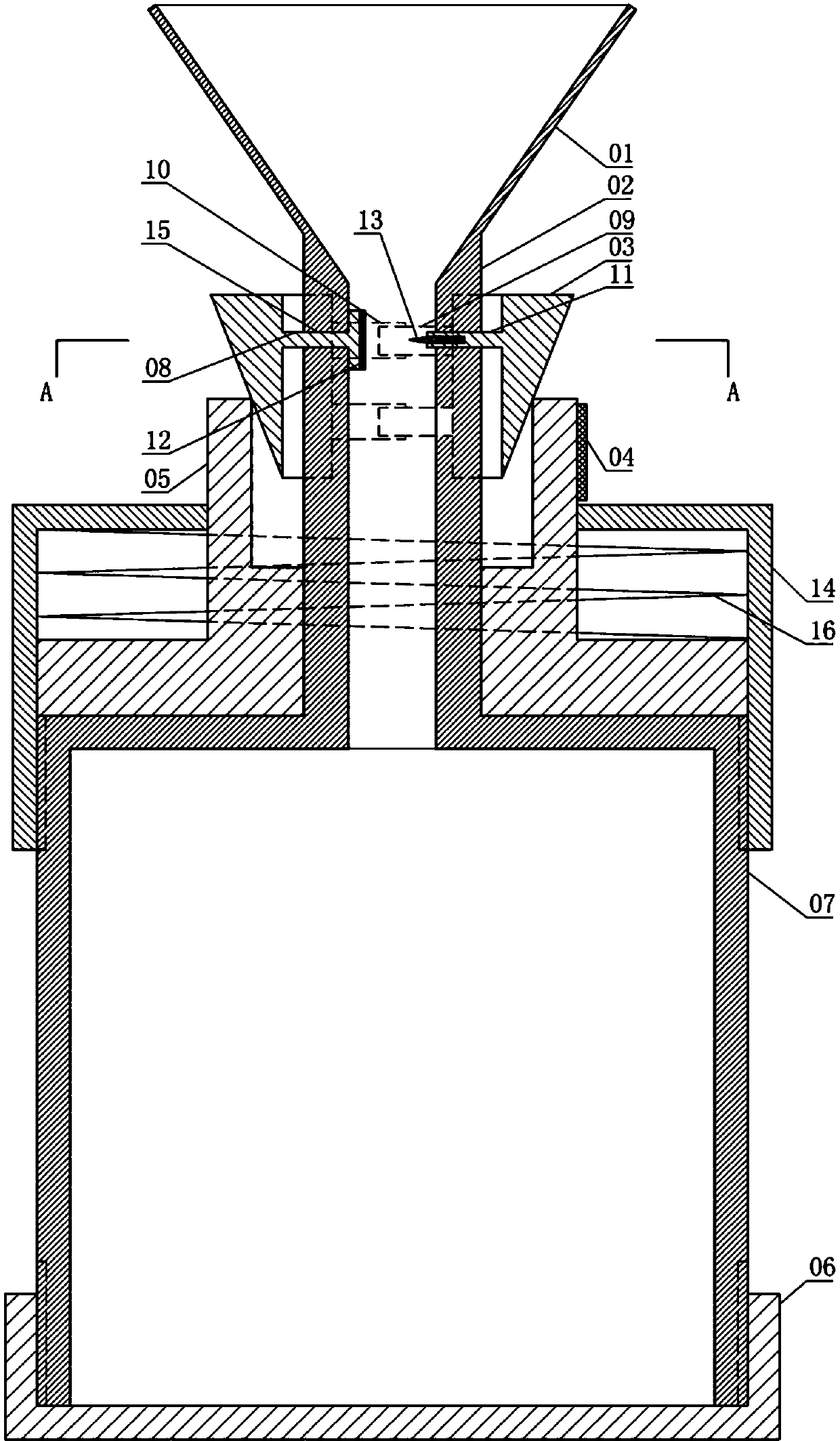

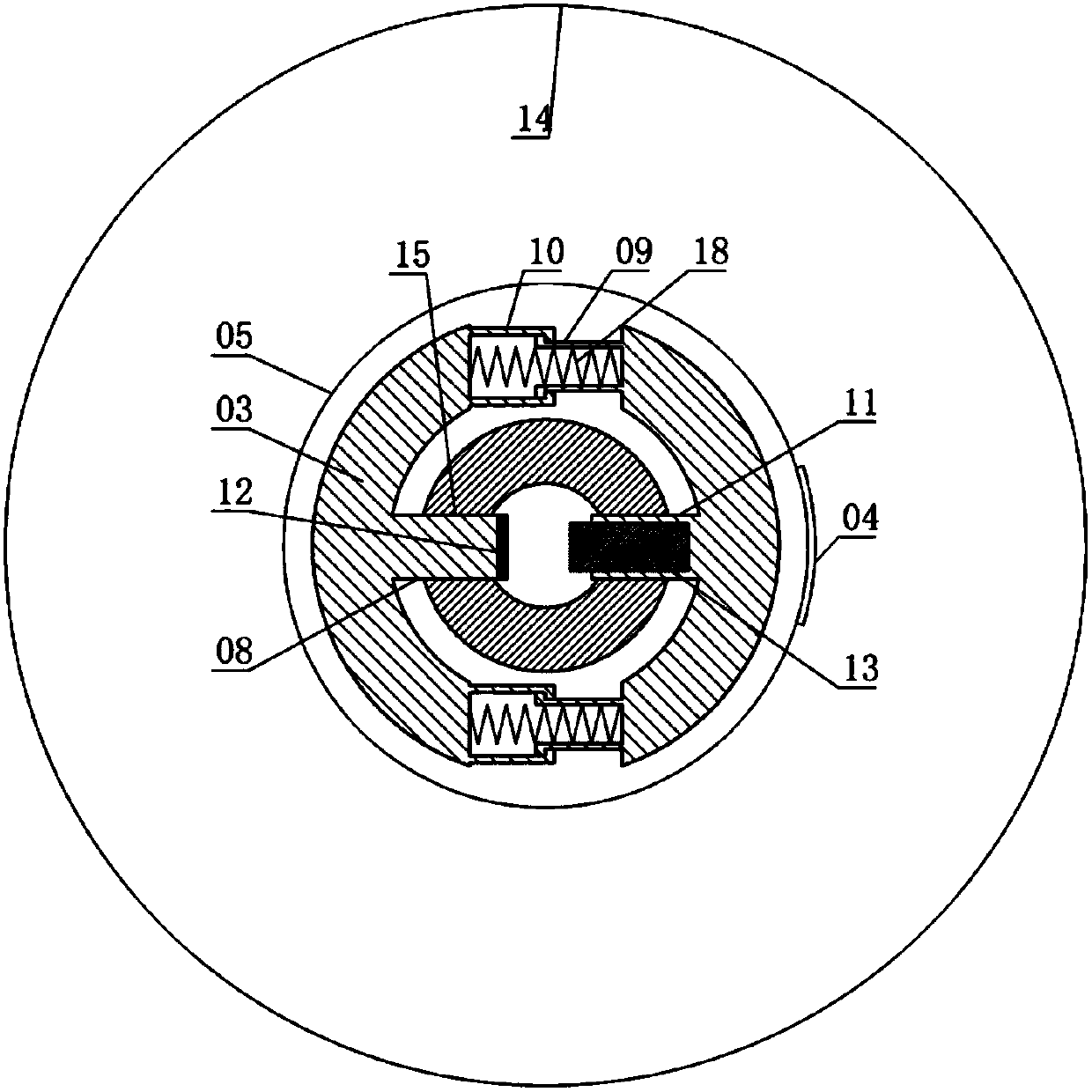

[0024] Displacement cutting sharps separation and recovery device consists of guide shield 01, cutting tube 02, pressure block 03, anti-skid pad 04, sliding cylinder 05, bottom cover 06, bottle body 07, left latch piece 08, guide shaft 09, guide Axle sleeve 10, right latch plate 11, cutting plate 12, blade 13, limit cover 14, latch opening 15 and return spring 16 constitute.

[0025] The cutting tube 02 is a vertical cylinder, and the side wall of the cutting tube 02 is provided with two latch openings 15 on the left and right. The lower end of the shield 01 and the cutting tube 02 is a cylindrical bottle body 07 integrated with the cutting tube 02, and the bottom of the bottle body 07 has a bottom cover 06 screwed together with the bottle body 07. The materials of the guide shield 01, the cutting tube 02 and the bottle body 07 are all transparent plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com