A rail vehicle pivoting arm type axle box positioning node assembly device

A technology for positioning nodes and rail vehicles, which is applied in the field of rail transit, and can solve problems such as the inability to ensure that the fastening force of bolts 3 is similar, the installation of positioning nodes 1 is not in place, and the labor intensity of operators is high, so as to overcome the rebound force and have strong versatility , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

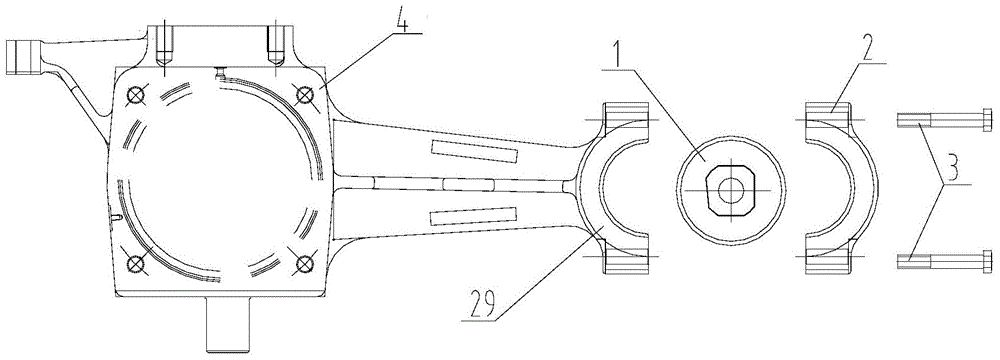

[0035] Such as figure 1 As shown, a rail vehicle pivoting arm type axle box positioning node assembly device provided by the present invention includes a positioning node 1, a gland 2, a bolt 3 and an axle box body 4, and the positioning node 1 passes through the gland 2 and four bolts 3 Installed on the end of axle box body 4. The assembly device is used to complete the assembly of the positioning node 1, the gland 2, the bolt 3 and the axle box 4.

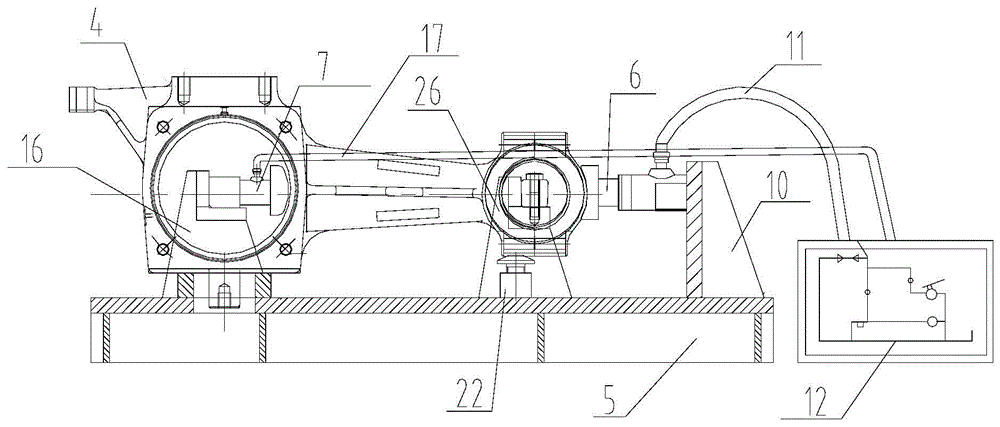

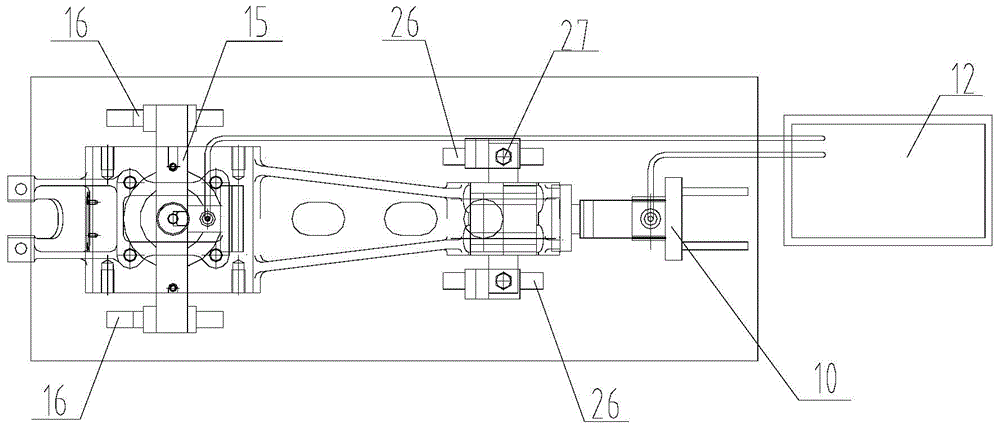

[0036] Such as figure 2 and image 3 As shown, the assembly device includes a press-fitting platform 5, a first clamping device 6 and a second clamping device 7, and the axle box 4, the positioning node 1, the first clamping device 6 and the second clamping device 7 are all fixed On the pressing platform 5. The first clamping device 6 presses the gland 2 from one side so that it is pressed ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com