Preparation method of ferroboron alloy coated lithium iron phosphate

A technology for coating lithium iron phosphate and boron-iron alloy, which is applied in the direction of lithium battery, positive electrode, active material electrode, etc., can solve the problems of large interface impedance between electrodes, poor interface compatibility, large interface resistance, etc., and achieve low interface resistance. , High density, the effect of reducing the interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The properties of the finally obtained lithium iron phosphate are shown in Table 3:

[0039] Example 3

[0040] The properties of the finally obtained lithium iron phosphate are shown in Table 4:

[0041] Example 4

[0042] The properties of the finally obtained lithium iron phosphate are shown in Table 5:

[0043] Example 5

[0044] The properties of the finally obtained lithium iron phosphate are shown in Table 6:

[0045] Example 6

[0046] Table 7 Example 6 lithium iron phosphate product performance

[0047] The properties of the finally obtained lithium iron phosphate are shown in Table 8:

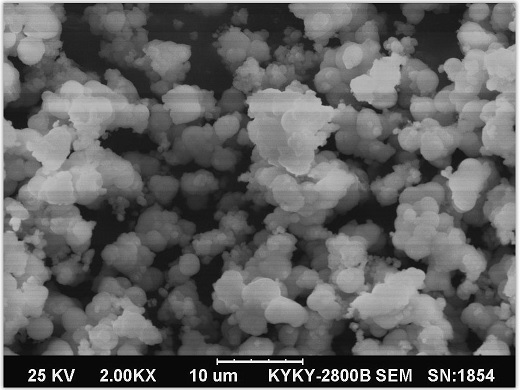

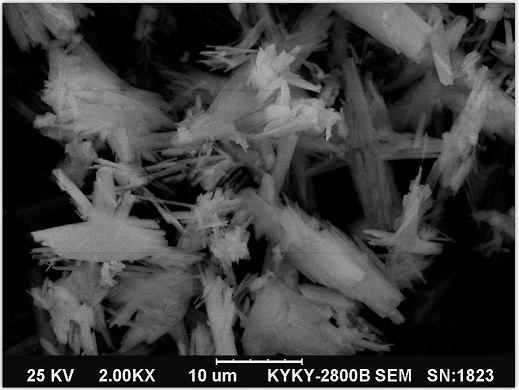

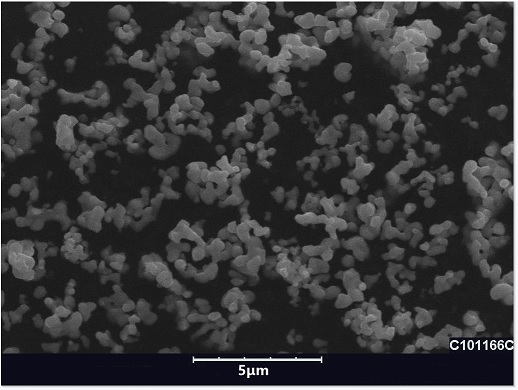

[0048] It can be seen from the above examples that the present invention eliminates or weakens the space charge effect by introducing a stable conductive buffer layer (iron-boron alloy), suppresses the generation of the interface layer, and reduces the interface resistance, thereby being suitable for use in solid-state battery materials; and due to the use of different T...

Embodiment 1

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com