First folding device in linen folding machine

The technology of a linen folding machine and a folding device is applied in the direction of a folder, a washing device, a laundry room device, etc., which can solve the problems of bending deformation of the conveying roller, high failure rate, low folding efficiency, etc., so as to avoid unfolding and falling. , The failure rate is low, and the effect of improving the folding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

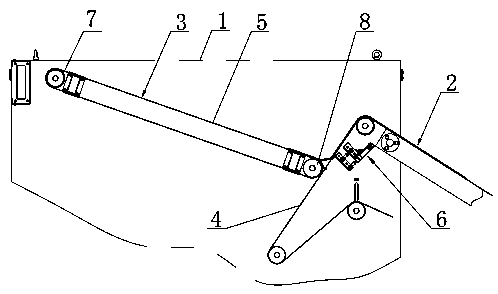

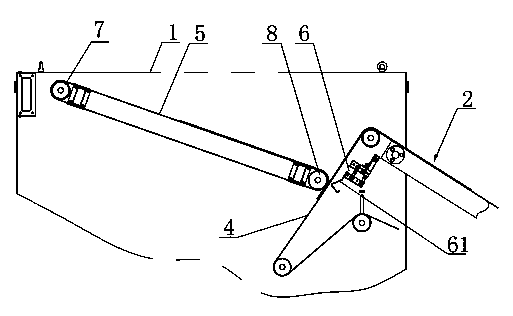

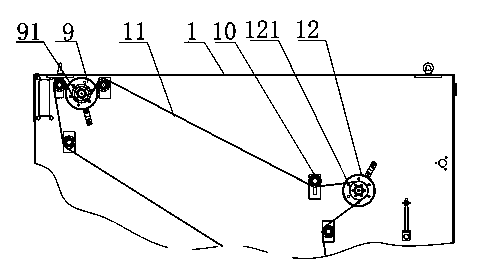

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the first folding and folding device in the linen folding machine includes: a frame 1, which is provided with a feed conveying mechanism 2 and a first folding conveying mechanism 3, and the feed conveying mechanism 2 includes: installed on the machine The feeding conveying roller set on the frame 1 and the feeding conveying belt 4 wound on the feeding conveying roller set, as well as the feeding driving device used to drive the feeding conveying belt 4 to run, can use a deceleration motor in actual work as The feeding driving device; the first folding conveying mechanism includes: the first folding conveying roller set and the first folding conveying belt 5 wound on the first folding conveying roller set, and the first folding conveying belt 5 for driving the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com