Double-station wide-travel clamping type fork for grabbing optical fiber discs

A technology of optical fiber disk and double station, applied in the direction of lifting device, etc., can solve the problems of unstable operation, low efficiency, and affecting the efficiency of optical fiber three-dimensional warehouse, and achieve the effect of improving the efficiency of entering and exiting the warehouse and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

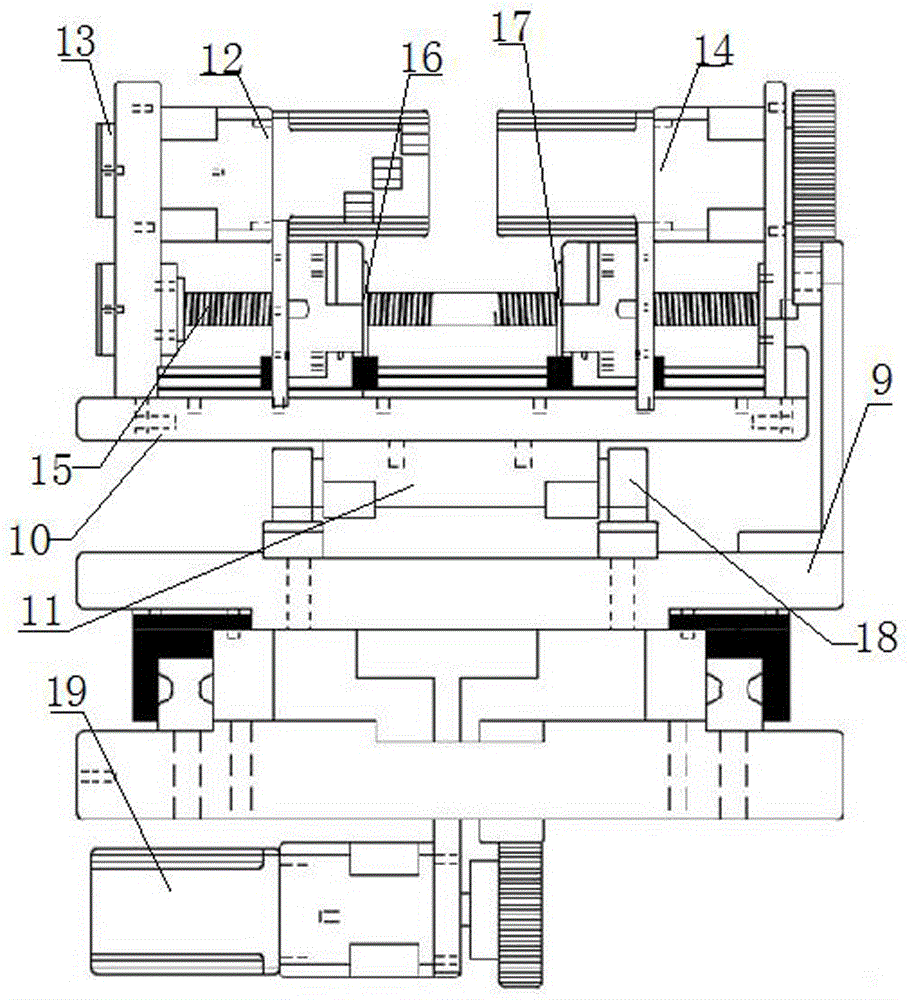

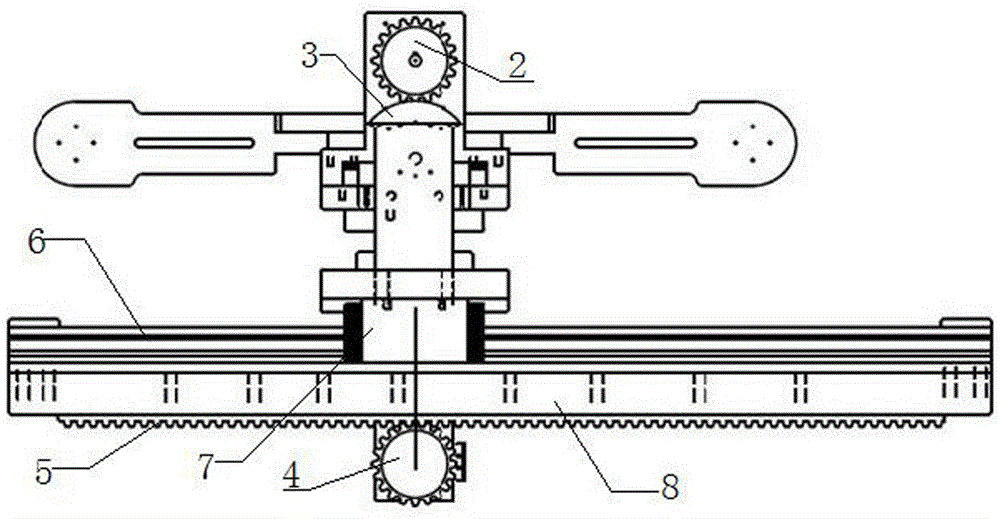

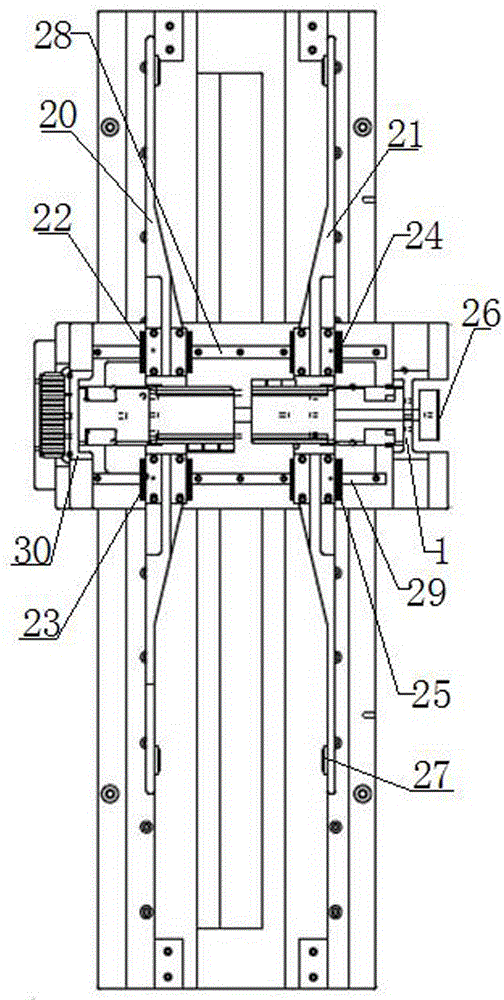

[0014] Such as Figure 1-3 As shown, a double-station wide-travel clamp-type fork for grasping an optical fiber reel includes a traveling motor 19, a fixed bottom plate 8, a moving pallet 9, a flipping fixed plate 10, a fork arm, and a traveling motor 19. A traveling gear 4 is installed at the end, a traveling slide rail 6 is installed on the upper part of the fixed base plate 8, a rack 5 is installed on the lower part, the rack 5 meshes with the traveling gear 4, a traveling slider 7 is arranged on the traveling slide rail 6, and the traveling slide The block 7 is provided with a movable carriage 9, and the movable carriage 9 is fixedly connected with an overturning seat 18 with an overturning shaft 11. The overturning seat 18 is provided with an overturning fixed plate 10, and both sides of the overturned fixed plate 10 are provided with lifting motor fixing seats. 30 and the clamping servo motor fixing seat 1, the lifting motor 14 with the lifting gear 2 is fixed on the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com