Coffee capsule clamping and discharging device for capsule coffee machine

A technology for coffee capsules and coffee machines, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of low stability, low reliability, waste of coffee capsules, and insufficient firm structure, and achieve compact structure, avoid waste, The effect of low unloading failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

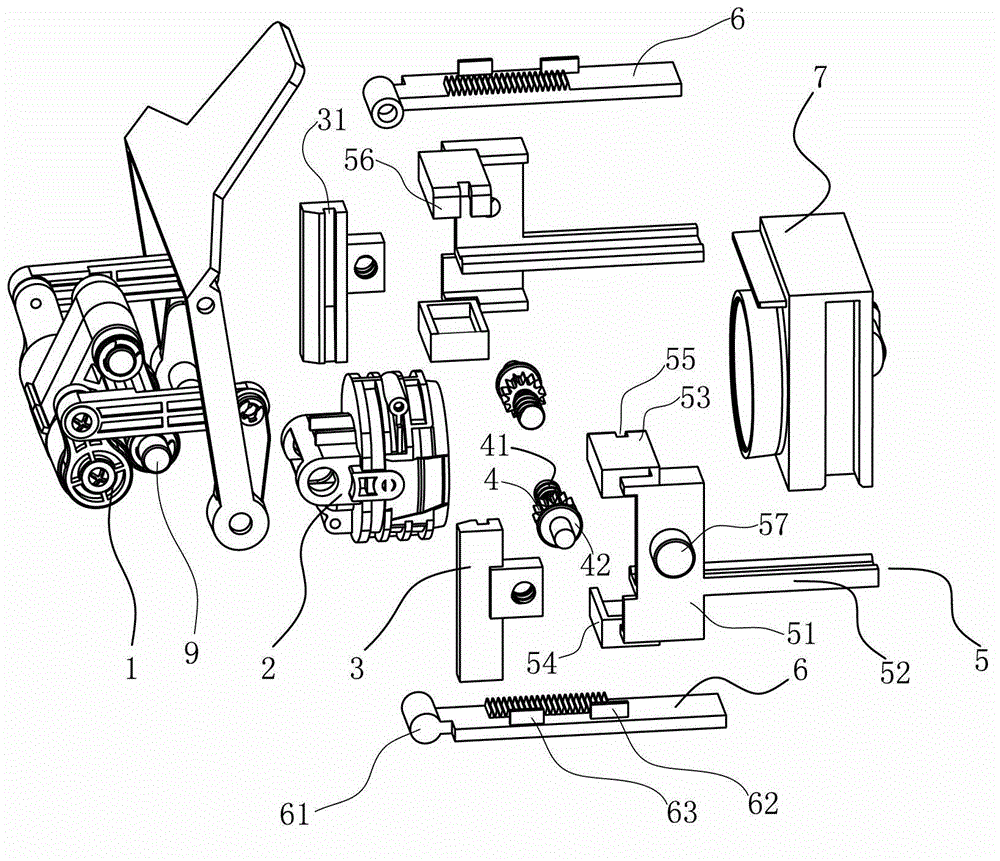

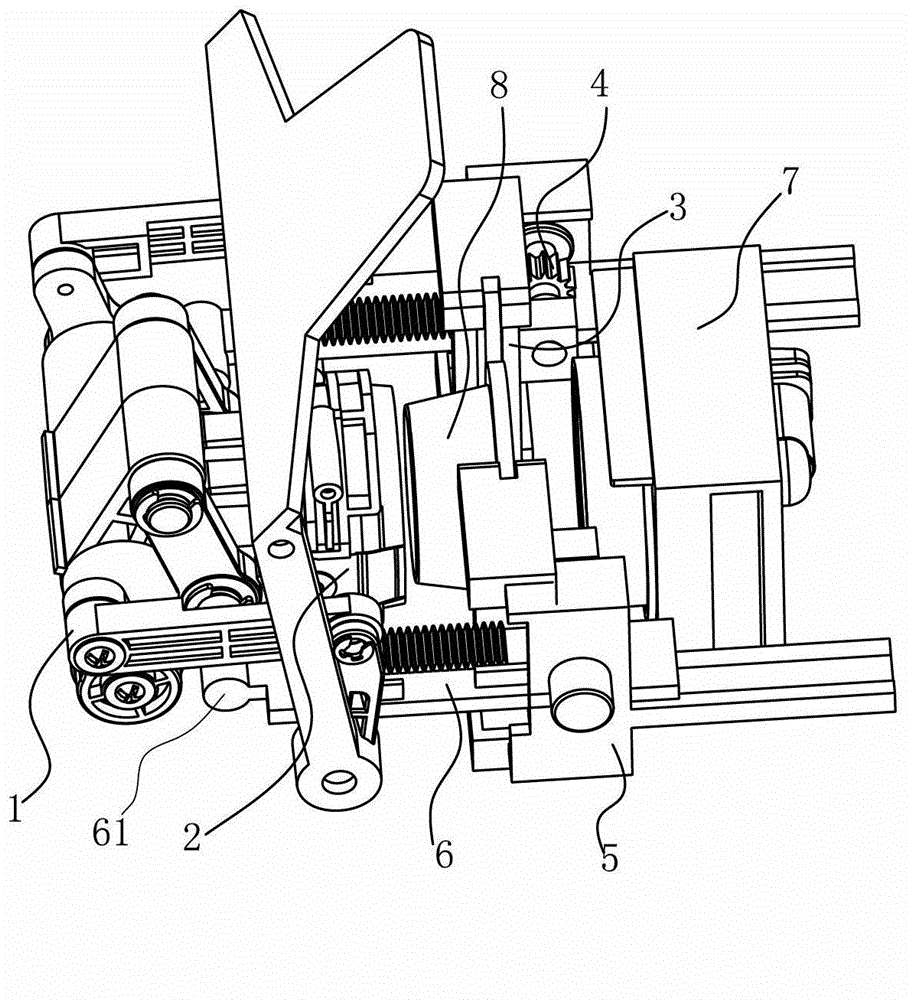

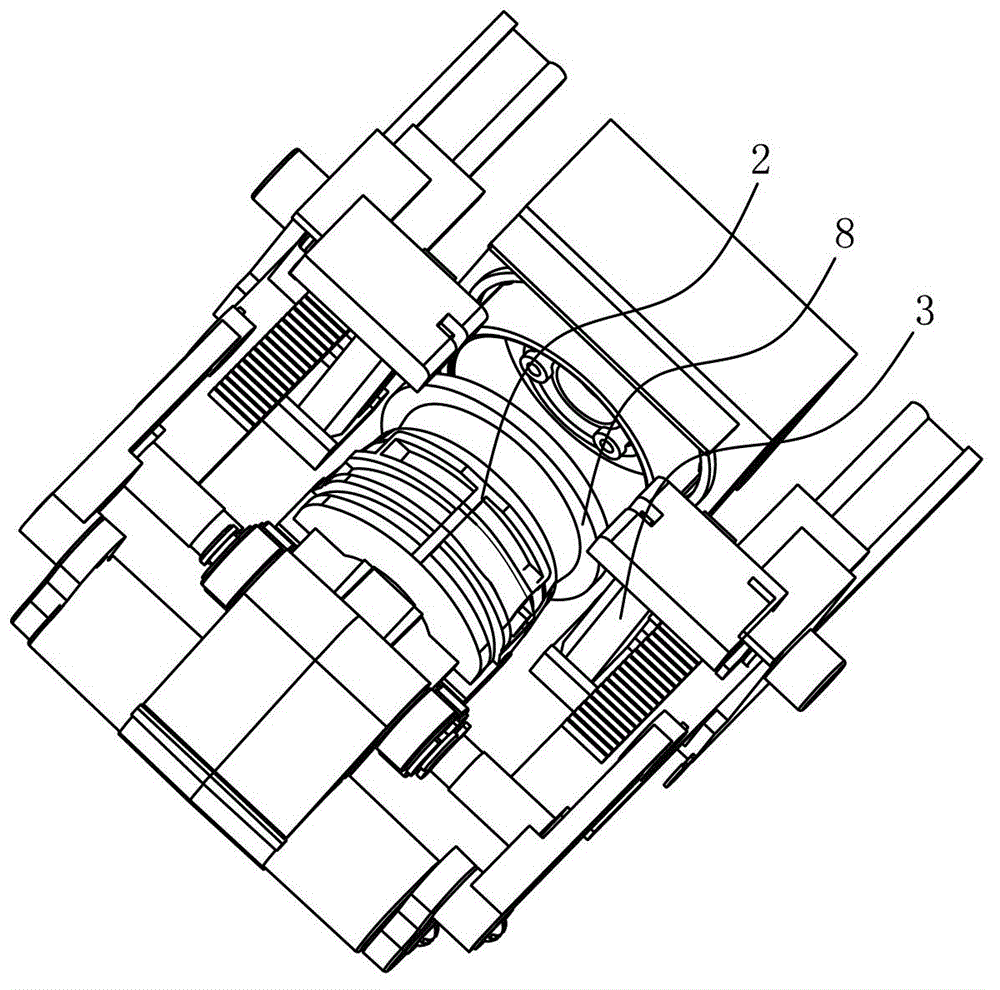

[0029] Such as figure 1 As shown in the coffee capsule clamping and unloading device for a capsule coffee machine, the brewing base 7 is located in front of the opening side of the brewing chamber, and the brewing chamber driving mechanism 1 moves the brewing chamber, and the brewing chamber is moved by two symmetrically arranged connecting shafts 9. The brewing chamber drive mechanism 1 is connected to the brewing chamber 2 . Both sides of the brewing base 7 are respectively provided with a fixed bracket 5, and the inboard of each fixed bracket 5 is equipped with a vertically arranged clamping and unloading bar 3 and a horizontal setting between the clamping unloading bar 3 and the inner wall of the fixing bracket 5. gear shaft 4. Each fixed bracket is made up of a vertical side plate 51 and upper and lower positioning plates 53, 54 formed on the same side of the vertical side plate, the upper positioning plate 53 is positioned at the top of the vertical side plate 51, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com