Totally-enclosed high-voltage resistant magnetomotive multi-ball injector

A high-pressure, magneto-dynamic technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of restricting the operation capacity and development efficiency of oil and gas fields, large and complex equipment, and high labor intensity, and achieve the effect of pitching Ideal, safe operation, small size of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

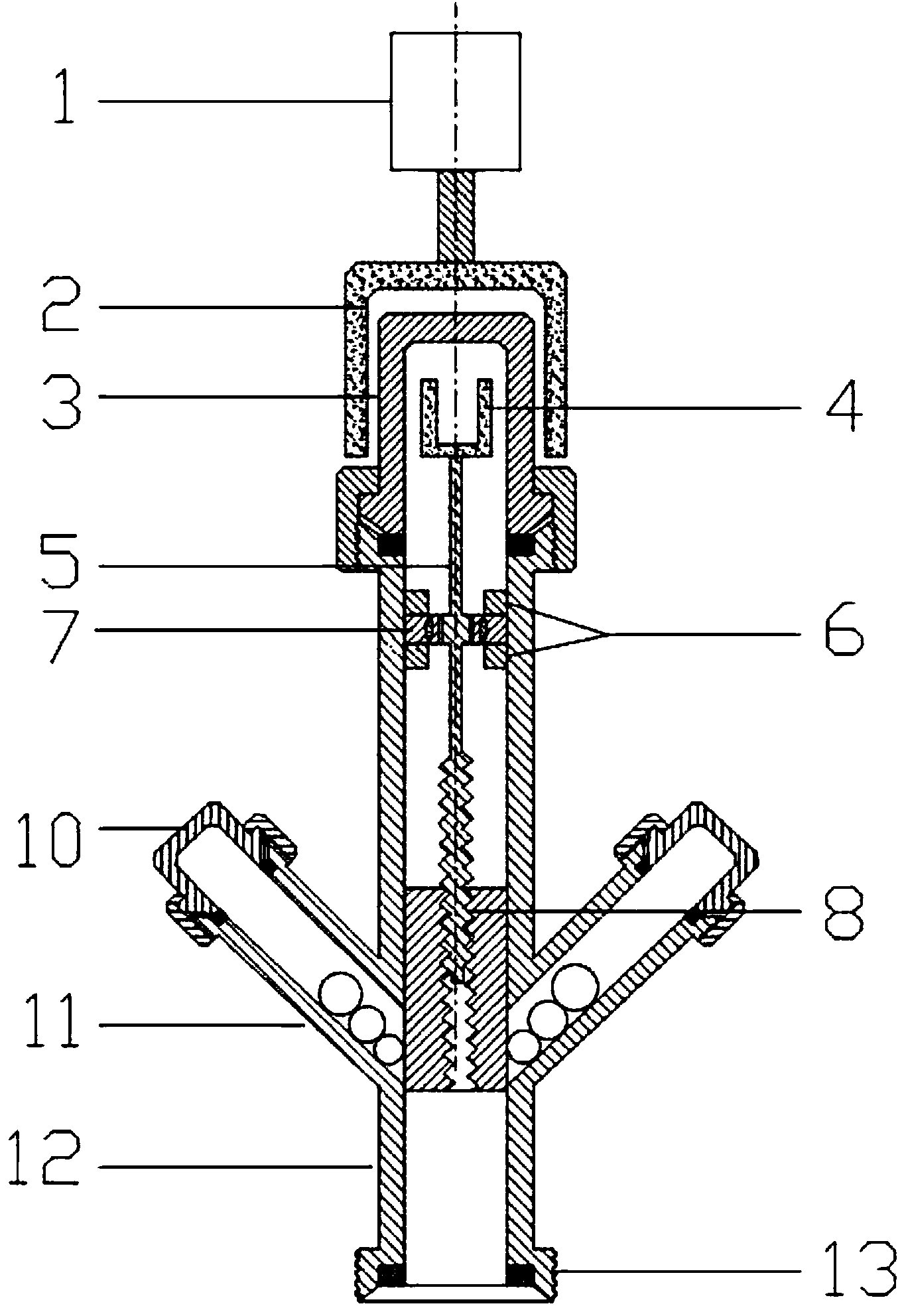

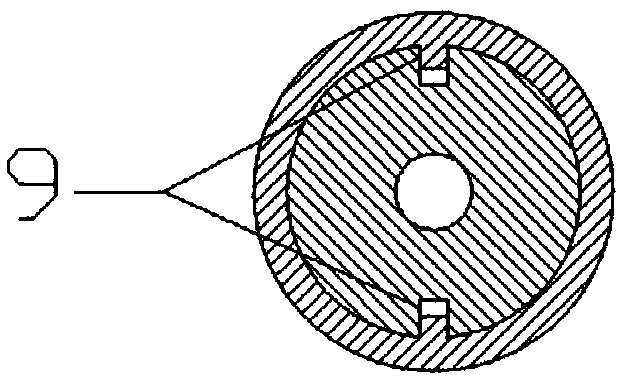

[0017] see figure 1 and figure 2 , the fully enclosed high-voltage resistant magnetic power multi-ball pitcher of the present invention comprises a housing 12, a union plug 3 sealed and installed on the upper end of the housing 12, a stepping motor 1 arranged above the union plug 3, and affixed to the On the output end of the stepping motor 1 and the strong magnetic active rotor 2 that can rotate around the union plug 3, the lead screw 5 that can be rotatably installed in the inner cavity of the housing 12, is fixed on the upper end of the lead screw 5 and can be rotated in a strong Driven by the magnetic active rotor 2, the driven rotor 4 that rotates, the ball selection stick 8 that is threadedly connected to the bottom of the lead screw 5, and two ball-loading tubes 11 that are arranged on both sides of the housing 12 are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com