Floating ball valve dedicated to high-pressure steam

A floating ball valve, high-pressure steam technology, applied in valve devices, engine components, cocks including cut-off devices, etc., can solve the problems of short life, long production cycle, poor performance, etc., achieve high pressure levels, achieve localization, resistance Excellent abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

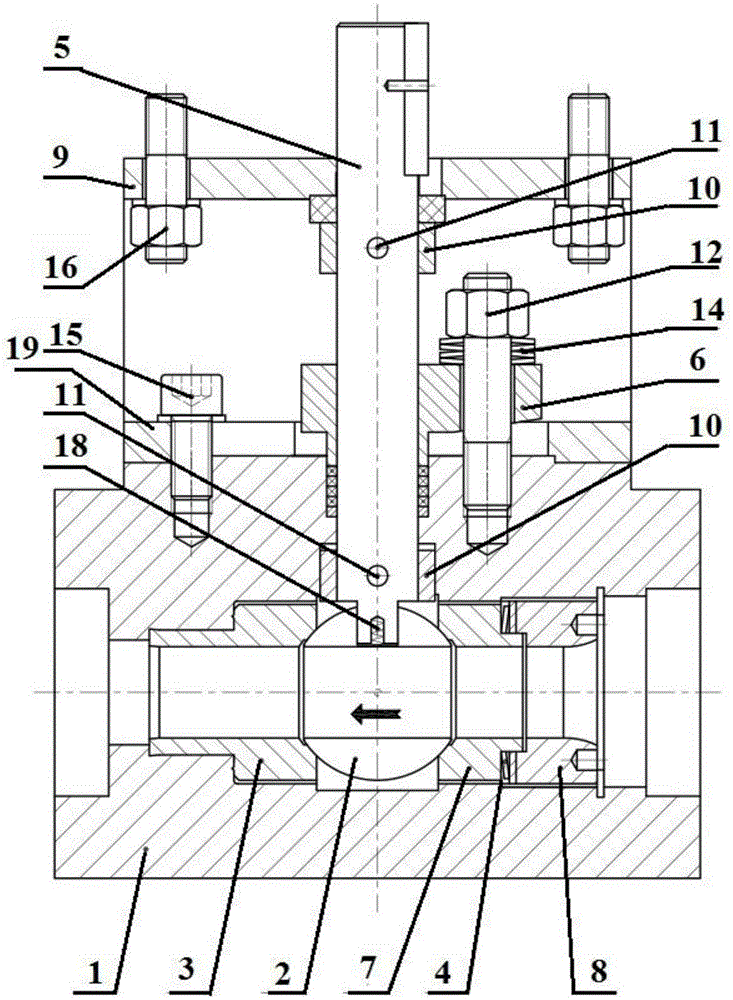

[0018] as attached figure 1 As shown, the special floating ball valve for high-pressure steam described in this embodiment includes a valve body 1, a ball body 2 and a valve stem 5, one end of the valve stem 5 is connected to the ball body 2, and the other end extends out of the valve body. The medium inlet side of the valve body is provided with a first metal valve body 7, the medium outlet side of the valve body is provided with a second metal valve seat 3, and the ball 2 is arranged on the first metal valve body. Between the seat 7 and the second metal valve seat 3, and the first metal valve seat 7 and the second metal valve seat 3 are attached to the ball 2 to form a metal sealing pair. The valve stem 5 and the valve body 1 are filled with valve stem packing, and the outer side of the first metal valve seat 7 is provided with a valve seat pressure ring 8, and the valve seat pressure ring 8 is screwed into the valve body 1, and is passed through the disc spring. 4 Press th...

Embodiment 2

[0021] In this embodiment, in order to endow the sphere with durability, wear resistance and corrosion resistance under high pressure and high temperature steam conditions, the valve seats (the first valve seat and the second valve seat) and the sphere are made of hardened steel become. The chemical composition of the hardened steel is as follows: 0.12-0.20wt% of C, 1.50-1.80wt% of Cu, 1.20-1.50wt% of Ni, 1.80-2.10wt% of Cr, 0.15-0.20wt% of Al, 0.15 ~0.50wt% Mo, 0.005~0.015wt% N, 0.002~0.005wt% B, Si≤0.5wt%, Mn≤0.5wt%, P≤0.030wt%, S≤0.030wt%, the balance is Fe and unavoidable impurities. Preferably, the content of C in the hardened steel is 0.12-0.15wt%, the content of Cu is 1.60-1.80wt%, the content of Ni is 1.25-1.35wt%, the content of Cr is 1.80-2.00wt%, and the content of Al The content of Mo is 0.18-0.20wt%, the content of Mo is 0.20-0.30wt%, the content of N is 0.008-0.015wt%, and the content of B is 0.002-0.003wt%. The hardened steel is casted, then treated with wate...

Embodiment 3

[0027] In this embodiment, a sealing coating is formed on the surface of the first metal valve seat facing the sphere through a laser cladding process, and the thickness of the sealing coating is 0.5mm˜5.0mm. The seal coat needs to combine good heat resistance, low friction and abrasion resistance. The raw material composition of the sealing coating is: 8.0-10.0wt% zirconium phosphate, 5.0-6.0wt% zirconium dioxide, 10.0-12.2wt% graphite, 10.0-12.0wt% chromium, 5.0-5.5wt% aluminum, 0.2-0.8wt% boron, and the rest nickel. The preparation method of the sealing coating is as follows: (1) prepare raw materials according to the above composition, and perform ball milling in a ball mill so that the particle size of the powder is 10 μm; (2) adopt a power density of 10 μm 4 W / cm 2 The laser beam is irradiated to form a molten pool, which is fed into the prepared raw material powder synchronously, and the powder-carrying gas is N 2The laser is a carbon dioxide gas laser, the scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com