Sealed range hood

A range hood, sealed technology, applied in the field of kitchen utensils, can solve the problems of low oil fume extraction efficiency, easy splashing of oil droplets, pollution of the kitchen environment, etc., to reduce the degree of oil adhesion, reduce the connection and penetration area, and improve the filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

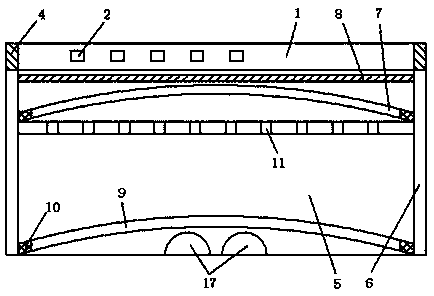

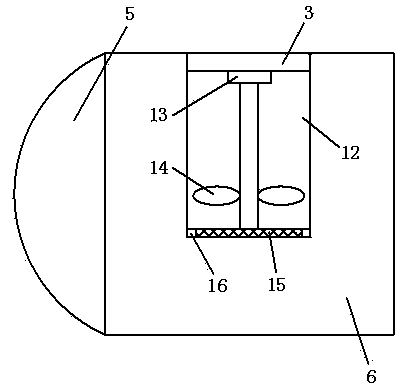

[0015] refer to Figure 1-2 , a specific embodiment of the present invention includes a casing 1, a control button 2 is arranged on the outside of the casing 1, a smoking port 3 is arranged on the inside of the casing 1, two chute 4 is arranged on the front side of the casing 1, and the chute 4 slides A transparent front baffle 5 is provided, transparent fixed side baffles 6 are provided on both sides of the housing 1, a first oil retaining groove 7 is provided on the lower edge of the front side of the housing 1, and a first oil retaining groove 7 is provided on the outside of the first oil retaining groove 7. The oil cleaning brush 8, the lower edge of the transparent front baffle 5 is provided with a second oil retaining groove 9, the first oil retaining groove 7 and the second oil retaining groove 9 are arcs raised in the middle, and the first oil retaining groove 7 and the two sides of the second oil retaining groove 9 are provided with oil-absorbing sponges 10 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com