An Improved Steam Flooding Oil Recovery Method

A steam flooding and steam technology, which is applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of short half-life of oil displacement effect, unfavorable heavy oil collection, etc., so as to reduce the steam injection rate and improve the heat resistance. , the effect of reducing the spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

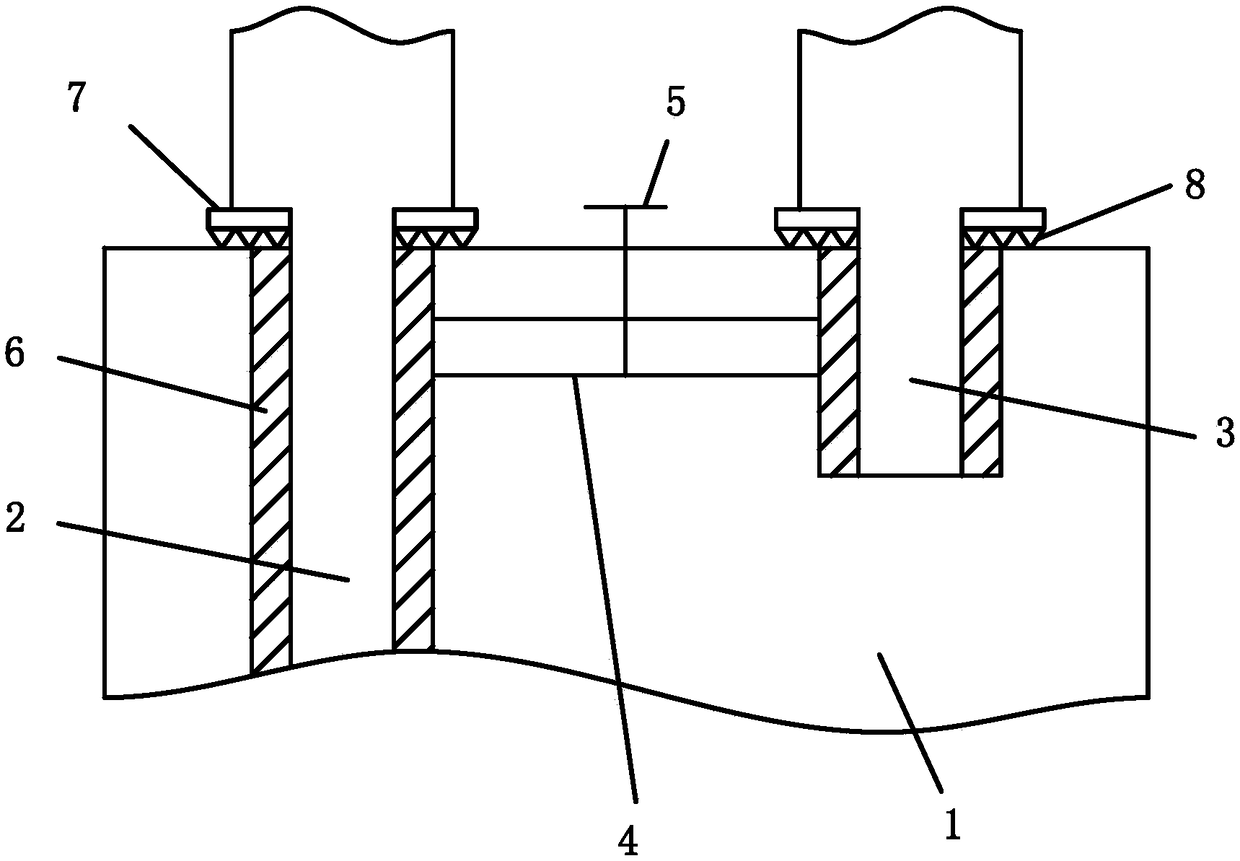

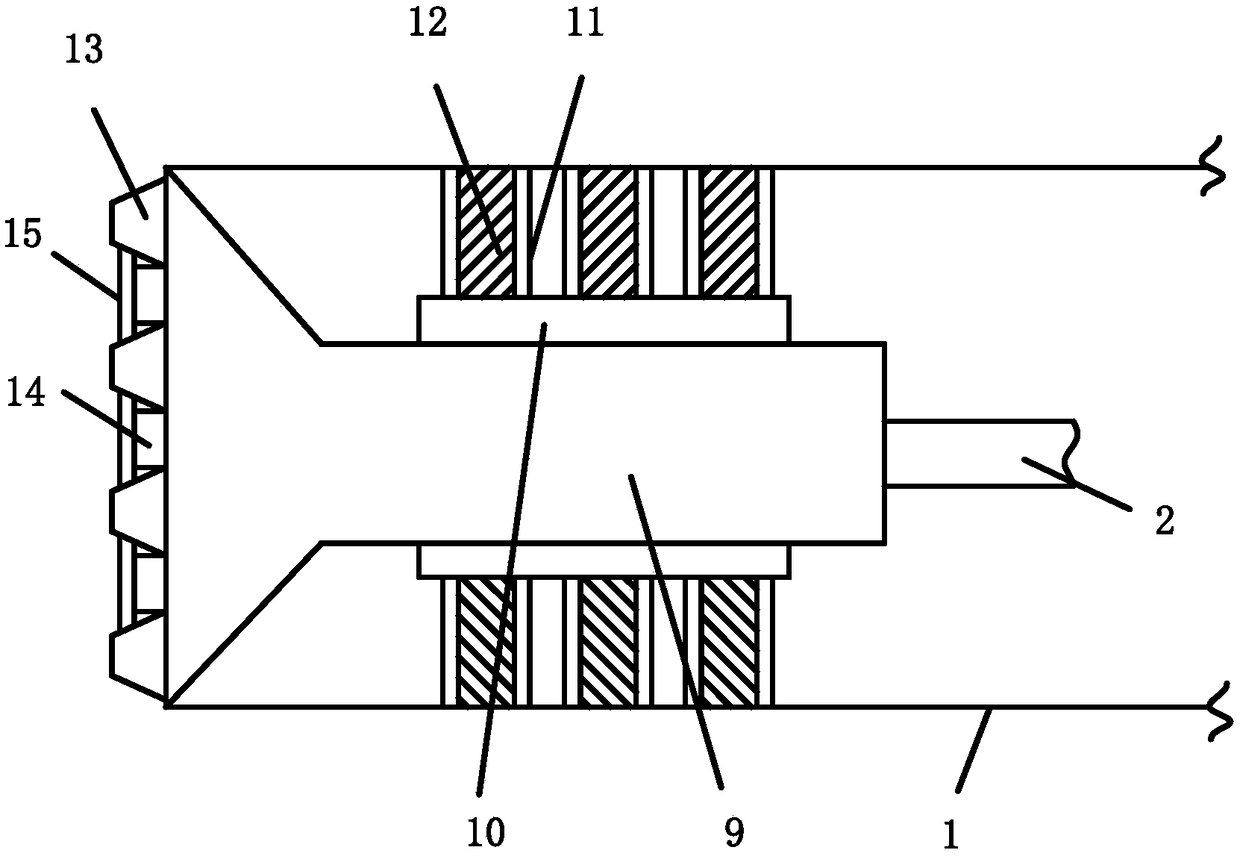

[0023] A specific embodiment of the invention comprises the following steps:

[0024] A. Inject steam into the injection well to build a steam cavity in the oil layer, and stew the well for 3 days;

[0025] B. The production well was put into production for 6 hours. During the production process of the production well, the mixture of steam and diluent was injected into the injection well synchronously, and then the well was soaked for 12 hours again; the above process was repeated 3 times;

[0026] C. Inject the mixture of steam and anti-coagulation agent into the production well, and resume production after 10 hours of simmering.

[0027] The diluent comprises the following components in parts by weight,

[0028] 22 parts of 2,2,2-trifluoroethyl methyl ether, 11 parts of p-chloroacetanilide, 5 parts of 2-thiophene methyl mercaptan, 1 part of 2',5'-dihydroxypropiophenone, 15 parts of 2-ethylbromobutane, 12 parts of 3-fluoro-o-xylene, 9 parts of trans-2,4-decadienal.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com