ZnO-based composite material, preparation method thereof and QLED device

A composite material and amine-based technology, which is applied in the field of QLED devices, ZnO-based composite materials and their preparation, can solve the problems of increasing interface complexity, high electron transmission rate, and small transmission barrier, so as to improve external quantum efficiency and use Lifetime, suppression of fluorescence quenching effects, and reduction of non-radiative recombination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In the present invention, the source of the ZnO nanoparticles is not particularly limited, and the ZnO nanoparticles can be prepared by a method well known to those skilled in the art. In the present invention, the preparation method of the ZnO nanoparticles preferably includes:

[0053] The soluble zinc salt solution is mixed with the alkali solution for hydrolysis reaction to obtain ZnO nanoparticles.

[0054] In the present invention, the solute of the soluble zinc salt solution is preferably one or more of zinc sulfate, zinc chloride, zinc nitrate, zinc acetate, zinc acetylacetonate and zinc gluconate.

[0055] In the present invention, the solvent of the soluble zinc salt solution is preferably water, ethanol, methanol, propanol, isopropanol, acetone, dimethyl sulfoxide, tetrahydrofuran, dimethylformamide, methyl acetate, ethyl acetate One or more of esters, propyl acetate, chlorobenzene and acetonitrile.

[0056] In the present invention, the concentration of th...

Embodiment 1

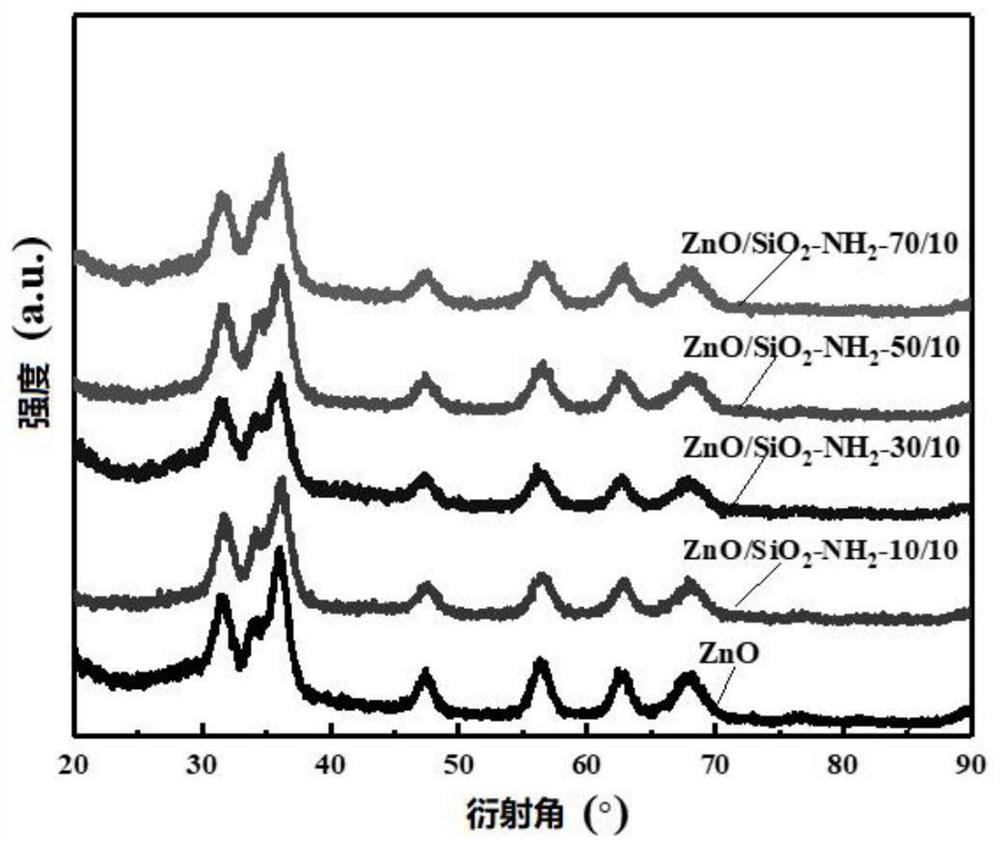

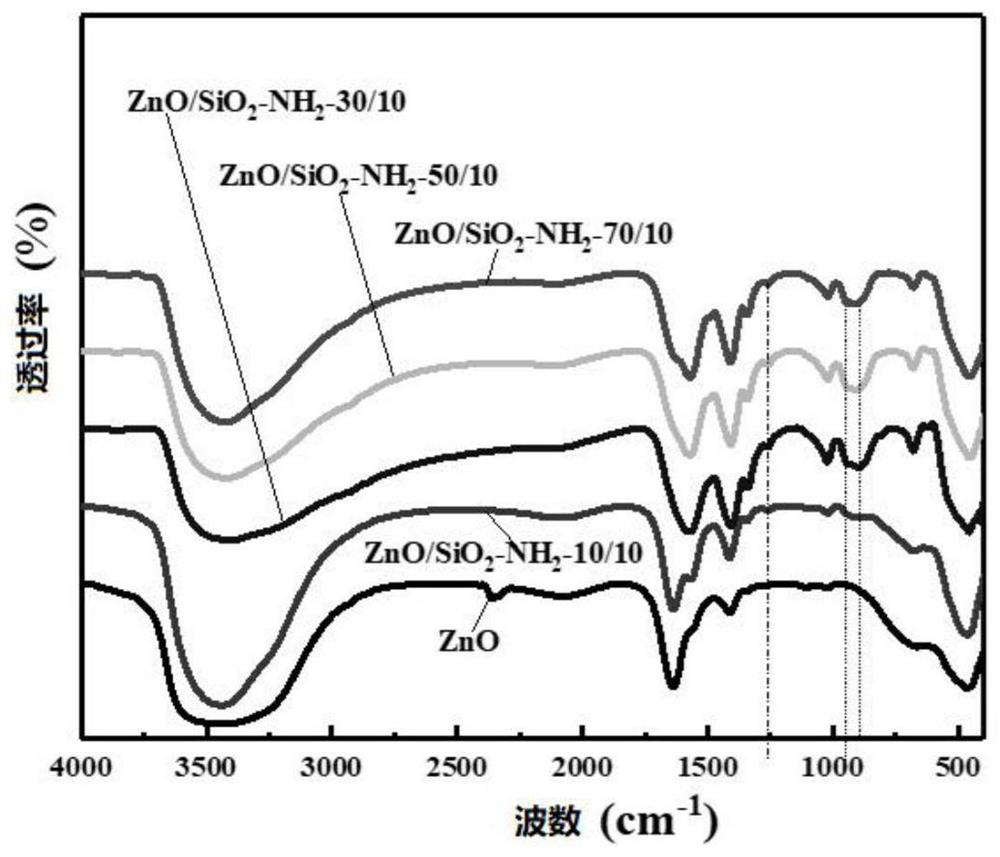

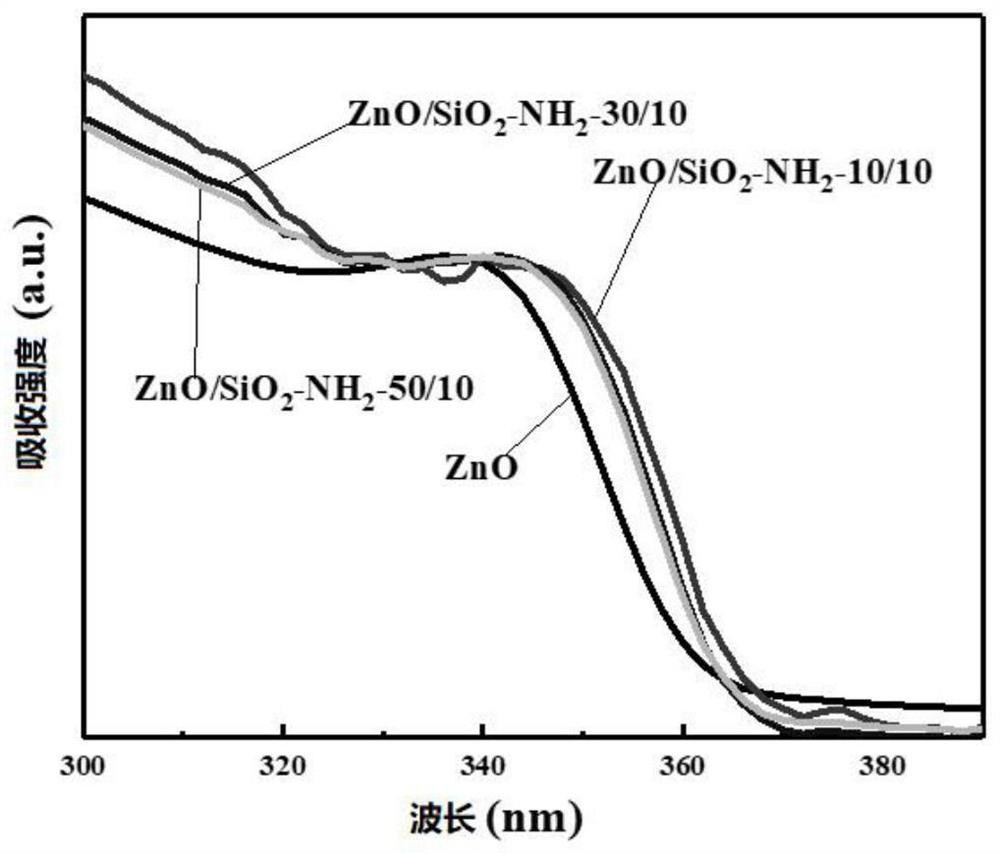

[0093] A ZnO-based composite material consisting of ZnO nanoparticles and SiO coated on the surface of the ZnO nanoparticles in turn 2 Coating layer and amine-modified SiO 2 cladding composition; the SiO 2 Coating layer and amine-modified SiO 2 The mass ratio of the coating layer is 1:1.

[0094] Among them, ZnO nanoparticles and SiO 2 The mass ratio of the cladding layer is 100:1.5; SiO 2 Coating layer and amine-modified SiO 2 The overall average thickness of the cladding layer is ~0.9 nm; the average particle size of the ZnO-based composite is 4.4 nm.

[0095] The ZnO nanoparticles used in this example were prepared by the following preparation method: dissolving zinc acetate in dimethyl sulfoxide to obtain a zinc acetate solution with a concentration of 0.1M, and dissolving tetramethylammonium hydroxide in absolute ethanol , to obtain a tetramethylammonium hydroxide solution with a concentration of 0.45M, the above two solutions were mixed under stirring conditions fo...

Embodiment 2

[0109] A ZnO-based composite material consisting of ZnO nanoparticles and SiO coated on the surface of the ZnO nanoparticles in turn 2 Coating layer and amine-modified SiO 2 cladding composition; the SiO 2 Coating layer and amine-modified SiO 2 The mass ratio of the coating layer is 3:1.

[0110] Among them, ZnO nanoparticles and SiO 2 The mass ratio of the cladding layer is 100:4.5; SiO 2 Coating layer and amine-modified SiO 2 The total average thickness of the cladding layer is 1.4nm; the average particle size of the ZnO-based composite material is 4.9nm.

[0111] The ZnO nanoparticles used in this example are the same as those in Example 1.

[0112] The preparation method of the above-mentioned ZnO-based composite material comprises the following steps:

[0113] (1) Mix ZnO nanoparticles (240mg) with solvent (40mL) (a mixture of absolute ethanol and dimethyl sulfoxide with a mass ratio of 1:5) and silicon source (ethyl orthosilicate, 10.8mg) carry out hydrolysis rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com