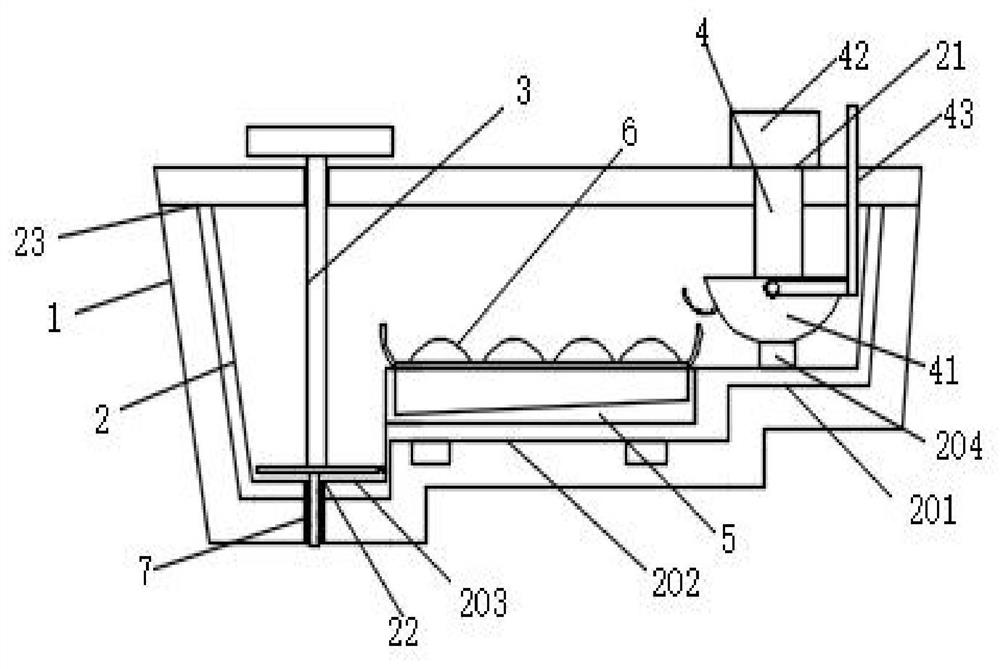

Tundish for molten steel casting

A tundish and molten steel technology, used in foundry equipment, casting melt containers, manufacturing tools, etc., can solve the problems of breakout, difficult salvage of sundries, and tundish damage, so as to improve quality, reduce collisions, and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

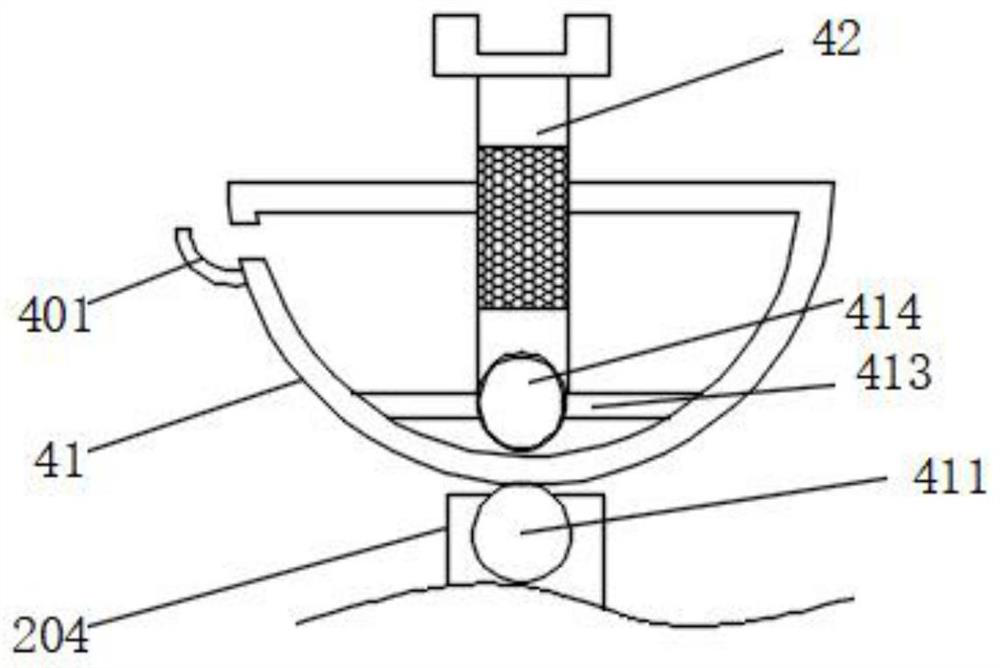

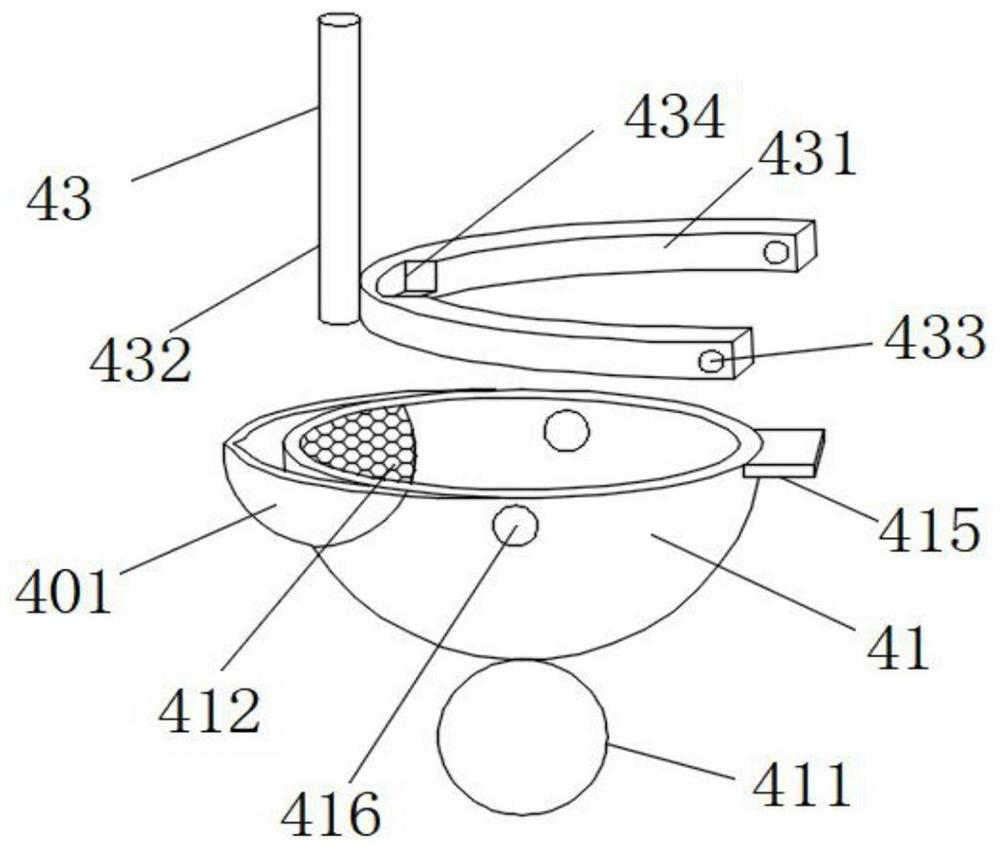

[0045] As an embodiment of the present invention, the lifting mechanism 43 is composed of a semicircular frame 431 and a straight rod 432, and the straight rod 432 is fixedly installed on the right outer surface of the semicircular frame 431, and the straight rod 432 runs through the top cover 23 , the semicircular frame 431 is clamped on the outside of the semicircular housing 41 at a position close to the right side of the upper end, and the front and rear ends of the semicircular frame 431 are provided with a second limiting hole 433 at a position close to the left side of the lower end. The second limiting hole 433 corresponds to the two first limiting holes 416, and the inside of the second limiting hole 433 and the first limiting hole 416 are connected with bolts. There is a rectangular slot 434, and the clamping plate 415 is clamped inside the rectangular slot 434. During operation, the lifting mechanism 43 is clamped inside the semicircular housing 41, and the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com