Detection method for degree of graphitization of cast iron

A technology of graphitization degree and detection method, applied in the direction of measuring device, specific gravity measurement, instrument, etc., can solve problems such as insufficient accuracy, troublesome operation, and inability to fully reflect the condition of cast iron, so as to ensure accuracy, improve testing rate, and measure The effect is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take the treated molten cast iron, pour it into the sand mold made by the sample mold, wait for the sample to cool, shot blast, polish the burrs, and then measure the weight with an electronic balance; then put the sample into a 500mml Put the water in a 1000ml measuring cup, then observe the scale line, and calculate the volume of the sample; divide the mass of the sample by the volume to get the density, and bring the density value into the formula to get the degree of graphitization of cast iron under this process condition.

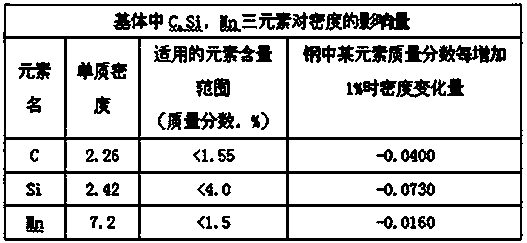

[0032] Cast iron can be seen as a steel matrix mixed with graphite flakes (balls), so the matrix has the properties of steel. Knowing the influence value of the main elements in the steel on the steel density, the corresponding approximate value of the steel density can be obtained. Among them, the calculation formula is: r1=7.88+nDr.X%, among them, r1-steel density (g / cm 3 ), 7.88-the density of pure iron (g / cm 3 ), the change in density (g / ...

Embodiment 2

[0058] Take the treated molten cast iron and pour it into the sand mold made of the blackened sample mold and the white sample mold for spectral analysis. After the sample is cooled, the blackened sample is shot blasted and the flash is polished. Burr, then use an electronic balance to measure the weight; then put the sample into a 1000ml measuring cup filled with 500mml of water, then observe the scale line to calculate the volume of the sample; divide the mass of the sample by the volume to obtain the density. After the spectroscopic sample is polished, the composition of the molten iron is determined. Bring the density value and composition value into the formula to get the degree of graphitization of cast iron.

[0059] Among them, the calculation formula is: r=1 / ((1-a%G) / r1+a%G / 2.26)=1 / ((1-a%G) / (7.88-0.04a(1-G) / (1-a%G)-0.073b / (1-a%G)-0.016 c / (1-a%G)+a%m / 2.26), r is the density of cast iron, r1 is the density of steel (g / cm 3 ), the degree of graphitization is G, the ...

Embodiment 3

[0064] Take the treated molten cast iron, pour it into the sand mold made by the sample mold, wait for the sample to cool, shot blast, polish the burrs, and then measure the weight with an electronic balance; then put the sample into a 500mml Put the water in a 1000ml measuring cup, and then observe the scale line to calculate the volume of the sample; divide the mass of the sample by the volume to obtain the density, and bring the density value into the formula to obtain the degree of graphitization of cast iron.

[0065] Among them, the calculation formula is: r=1 / ((1-a%G) / r1+a%G / 2.26)=1 / ((1-a%G) / (7.88-0.04a(1-G) / (1-a%G)-0.073b / (1-a%G)-0.016 c / (1-a%G)+a%m / 2.26), r is the density of cast iron, r1 is the density of steel (g / cm 3 ), the degree of graphitization is G, the composition: C:a%, Si:b%, Mn:c%; from the above formula we can see that there are only 2 unknowns in the formula, we calculate the degree of graphitization in cast iron according to the matrix density , so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com