Corrosion testing device for metal inside gaps under stripped coatings

A technology of metal corrosion and testing equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of anti-corrosion coating loss of cohesion, pipeline corrosion, etc., and achieve simple structure, convenient operation, and detection high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

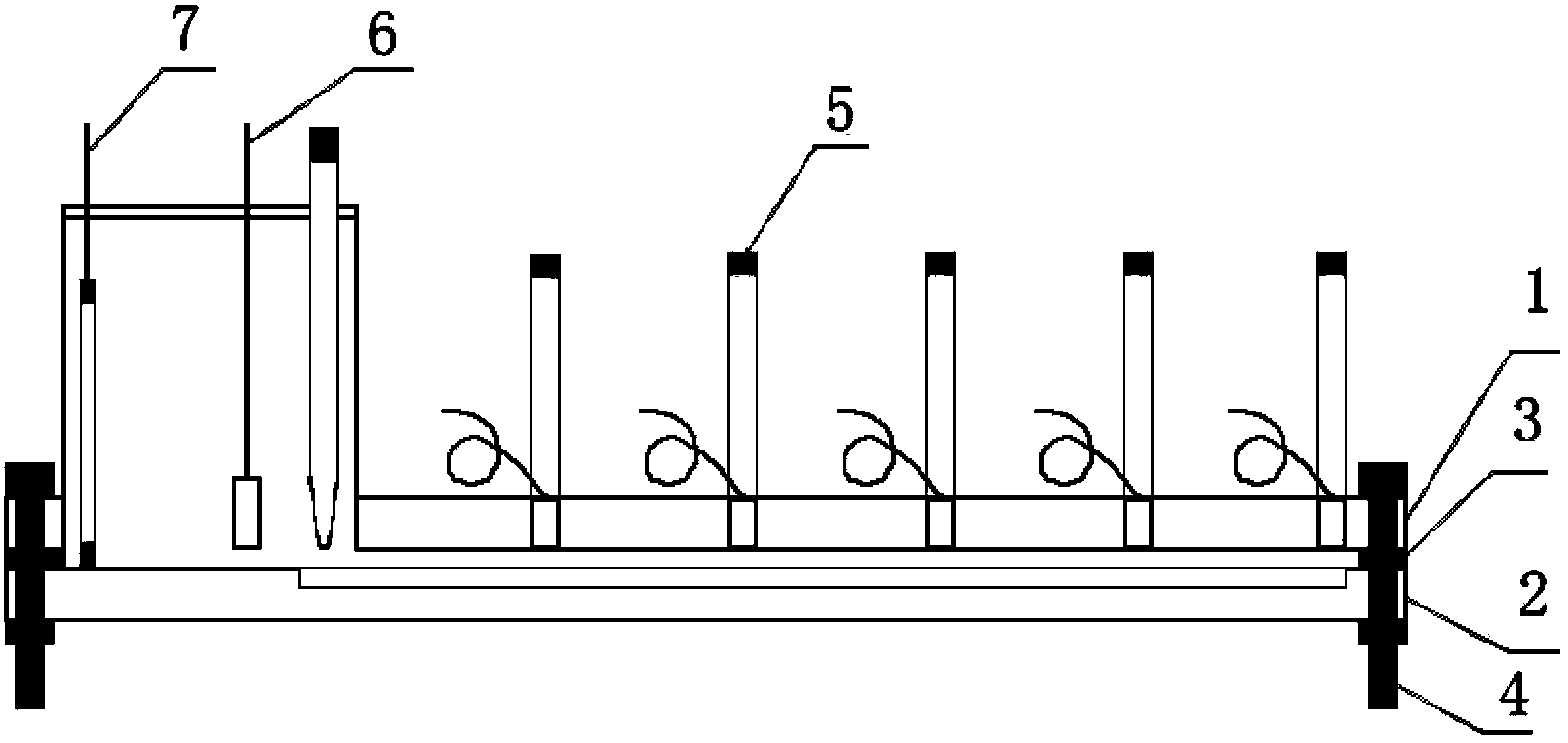

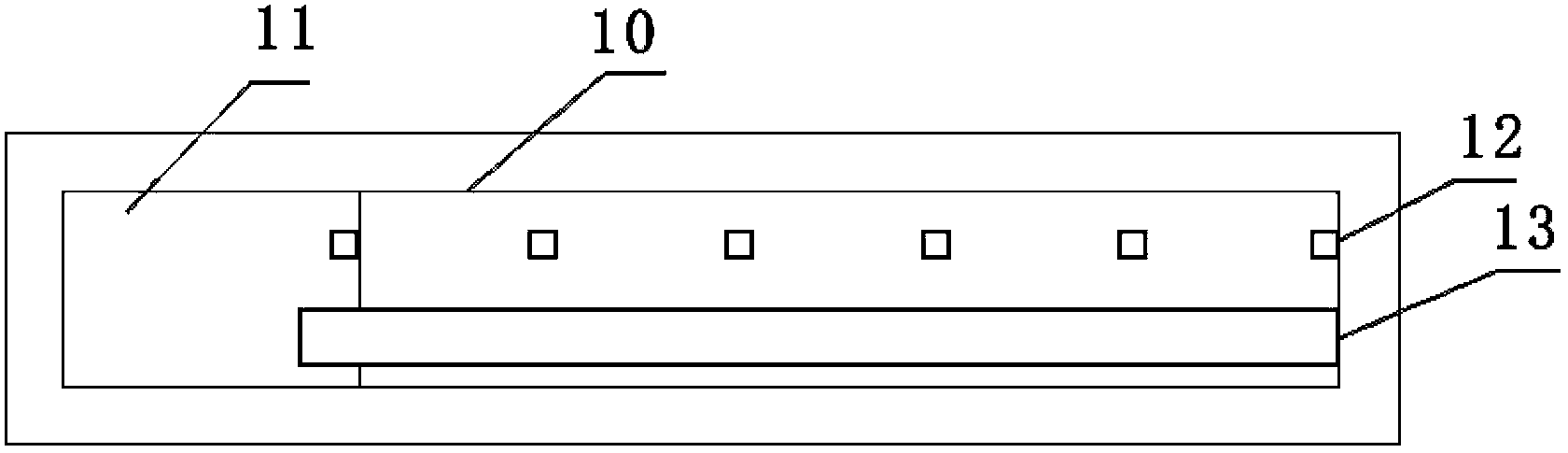

[0022] like Figure 1~3 As shown, the metal corrosion test device in the gap under the stripping coating of the present invention includes a base plate 2, a cover plate 1 placed on the base plate 2 and fixed with the base plate 2, wherein a gap is left between the cover plate 1 and the base plate 2, and the cover plate 1 and the two ends of the bottom plate 2 are sealed and fixed together by rivets 4, and a gasket 3 with a thickness is arranged between the cover plate 1 and the bottom plate 2 to form a gap. In this embodiment, the gasket 3 is made of PTFE material.

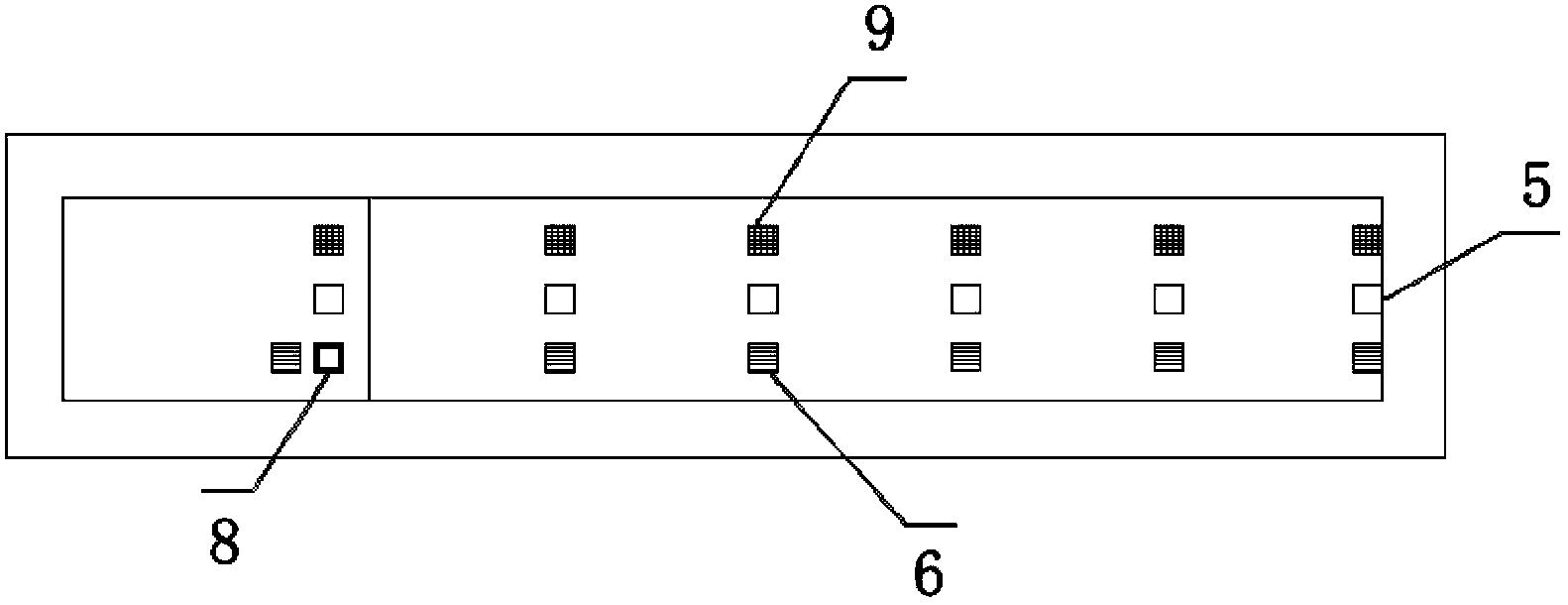

[0023] One side of the cover plate is the solution area 11 ( image 3 ), the solution area 11 communicates with the gap area, and more than two salt bridges 5 are evenly spaced on the other side to connect with the reference electrode, and the gap area 10 is between the salt bridges ( image 3 ). In the present embodiment, the number of salt bridges is 5, and auxiliary electrodes 9 and composite microelectrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com