Assembling and welding device

A welding equipment and welding device technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of hidden safety hazards for operators, low work efficiency, and prone to unqualified products, etc., to reduce operating costs The effect of wide range, high production efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

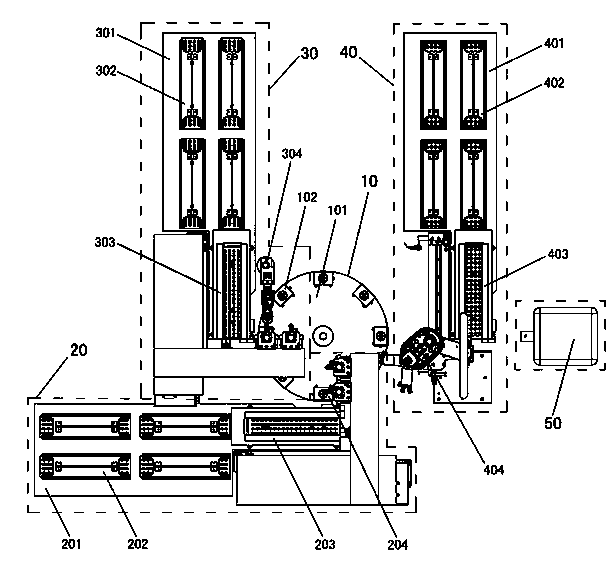

[0028] Such as figure 1 As shown, the assembly and welding equipment of the present invention includes a turntable device 10, a first automatic feeding device 20, a second automatic feeding device 30, an automatic unloading device 40 and a welding device 50, and in this embodiment, the The turntable device 10 is located in the middle of the first automatic loading device 20 , the second automatic loading device 30 and the automatic unloading device 40 , so as to conveniently and quickly realize the loading and unloading operation of the assembled components.

[0029] Specifically, the turntable device 10 includes a turntable 101 and an auxiliary jig 102 disposed on the turntable 101 for placing workpieces.

[0030] The first autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com