Automatic torque return wind load avoiding mechanism

An automatic avoidance and wind load technology, applied in the directions of signs, instruments, display devices, etc., to achieve the effect of increasing the amount of steel, simplifying maintenance work, and eliminating manual reset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

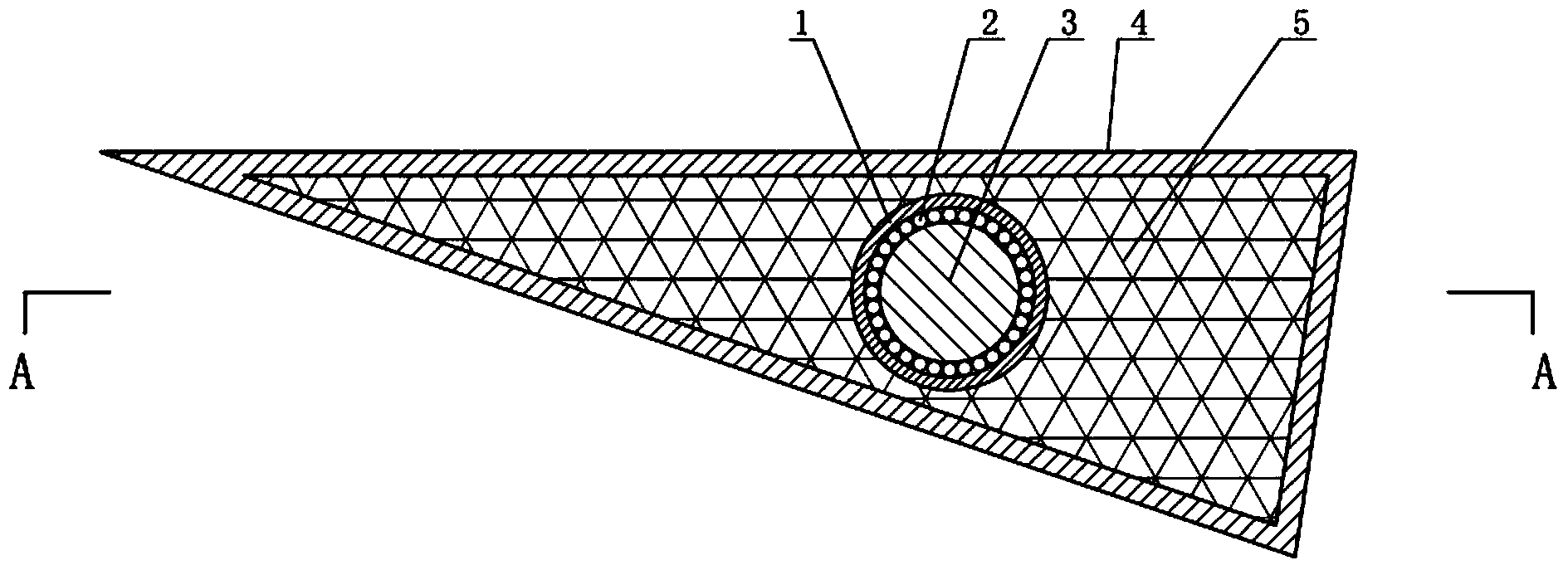

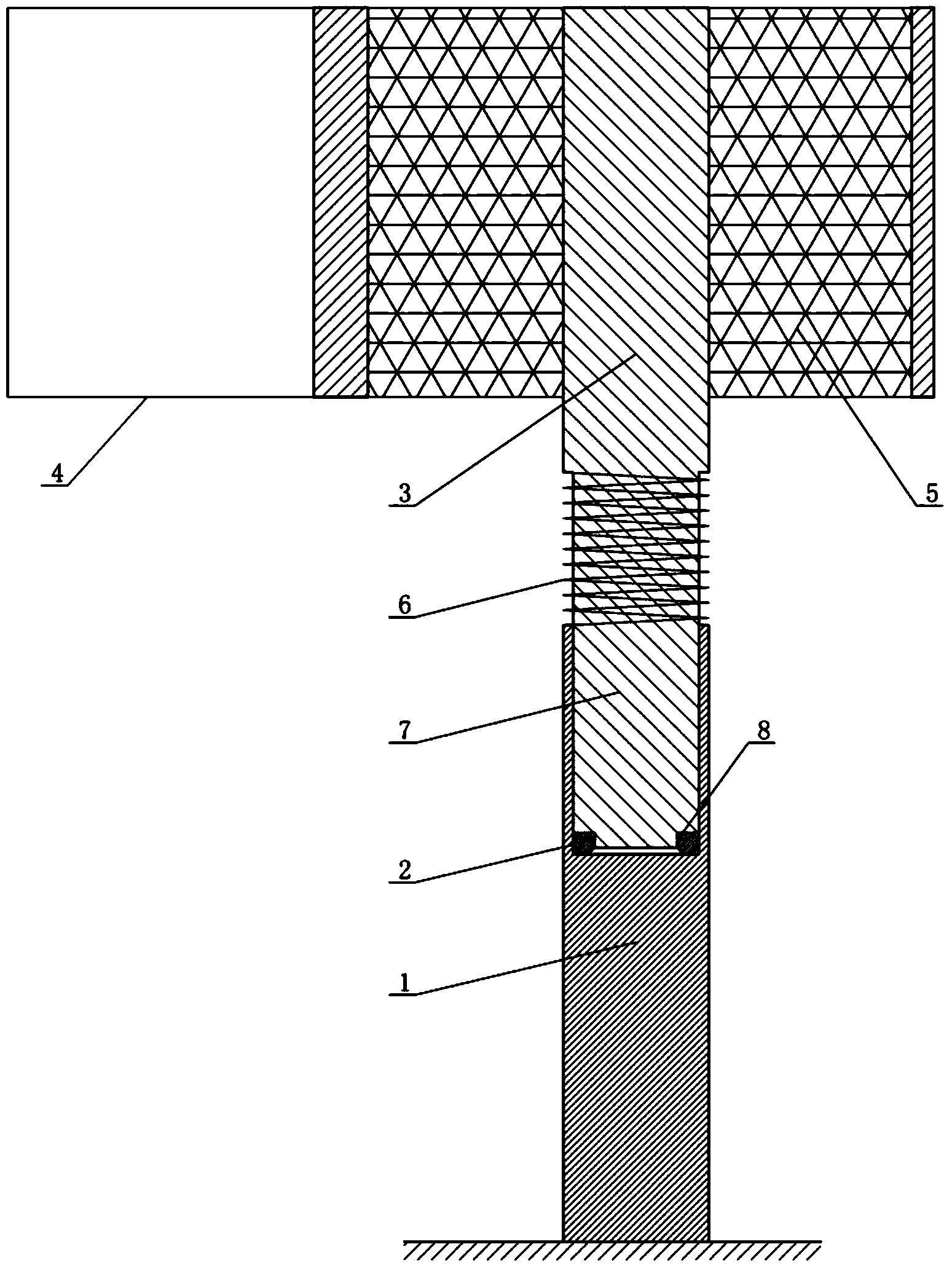

[0014] The torque return wind load automatic avoidance mechanism is composed of a mother column 1, a steel ball 2, a child column 3, a panel 4, a steel structure frame 5, a torsion spring 6, a rotating shaft 7 and steps 8. Three rectangular panels 4 are connected end to end to form a triangular prism, and the horizontal projection of the triangular prism is an isosceles triangle. The apex angle of the isosceles triangle is not greater than 30°, the vertically arranged sub-column 3 is located in the triangular prism, and the center of gravity of the isosceles triangle is located on the axis of the sub-column 3 . There is a steel structure frame 5 between the inner wall of the panel 4 and the sub-column 3, and the steel structure frame 5 is welded together with the inner wall of the panel 4 and the sub-column 3 as a whole. The lower end of the sub-column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com