Fracture-resistance copper and aluminum transition plate

A technology of anti-fracture and transition plate, which is applied in the direction of connecting contact materials, electrical components, clamping/spring connections, etc., to ensure rigidity and avoid fatigue fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The specific embodiment: the best embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

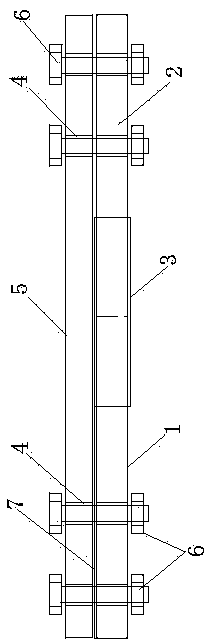

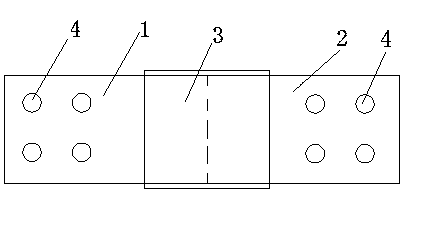

[0017] Embodiment: a kind of fracture-resistant copper-aluminum transition plate (see figure 1 , figure 2 ), which includes a copper end plate 1, the copper end plate 1 is fixedly connected to the aluminum end plate 2, and an anti-corrosion tube 3 is arranged outside the connection between the copper end plate 1 and the aluminum end plate 2, and the anti-corrosion tube 3 adopts heat Shrink tube or cold shrink tube, copper end plate 1 is provided with four fixed connection holes 4, the four fixed connection holes 4 are arranged in a rectangular shape, aluminum end plate 2 is provided with four fixed connection holes 4, the four A fixed connection hole 4 is arranged in a rectangle, and the copper end plate 1 and the aluminum end plate 2 are connected with a strip aluminum plate 5 by a bolt 6 through the fixed connection hole 4 . An insulating layer 7 is provided between the strip-shaped aluminum plate 5 and the copper end plate 1 to avoid electric corrosion; the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com