Batch preparation device and method of scanning tunneling microscope (STM) probes

A preparation device and probe technology, which is applied in the batch preparation device and field of STM probes, can solve the problems of time-consuming and labor-consuming, single STM probe preparation, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

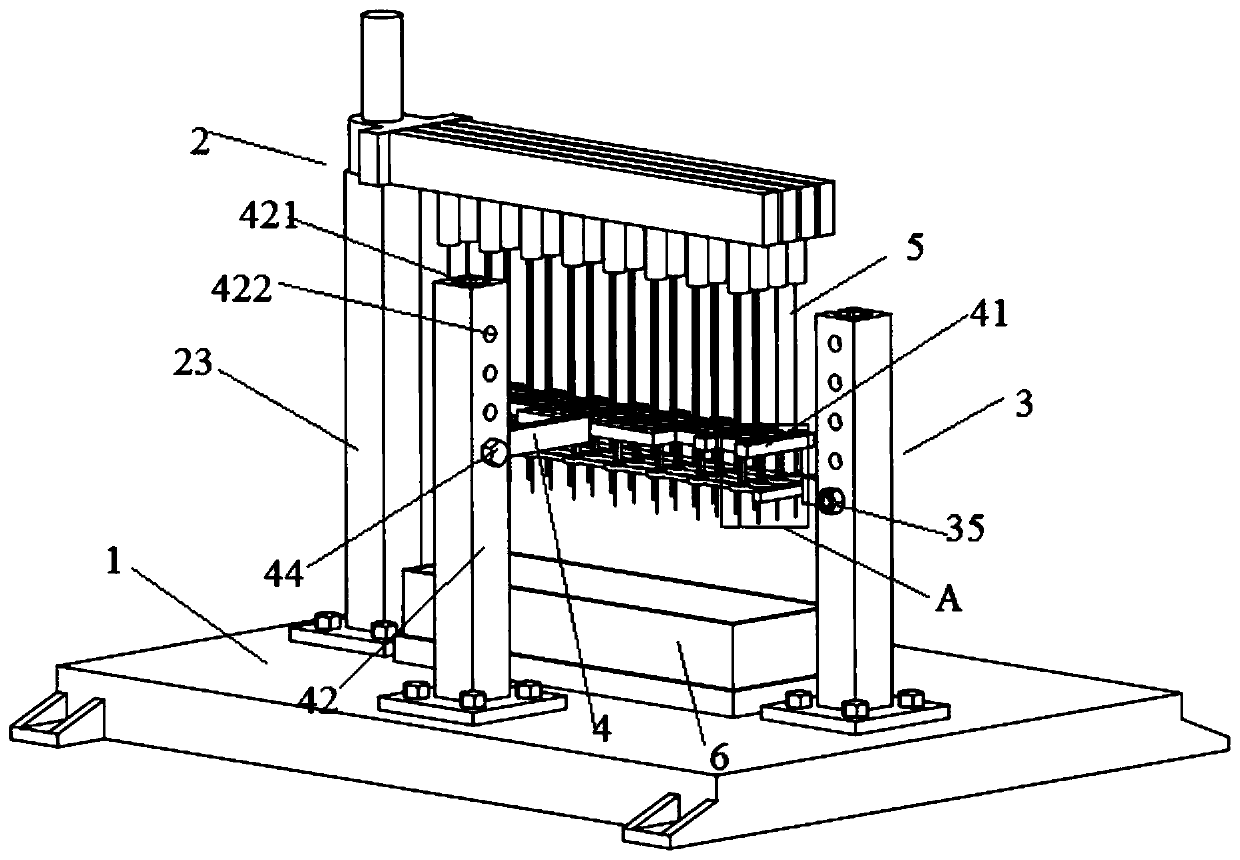

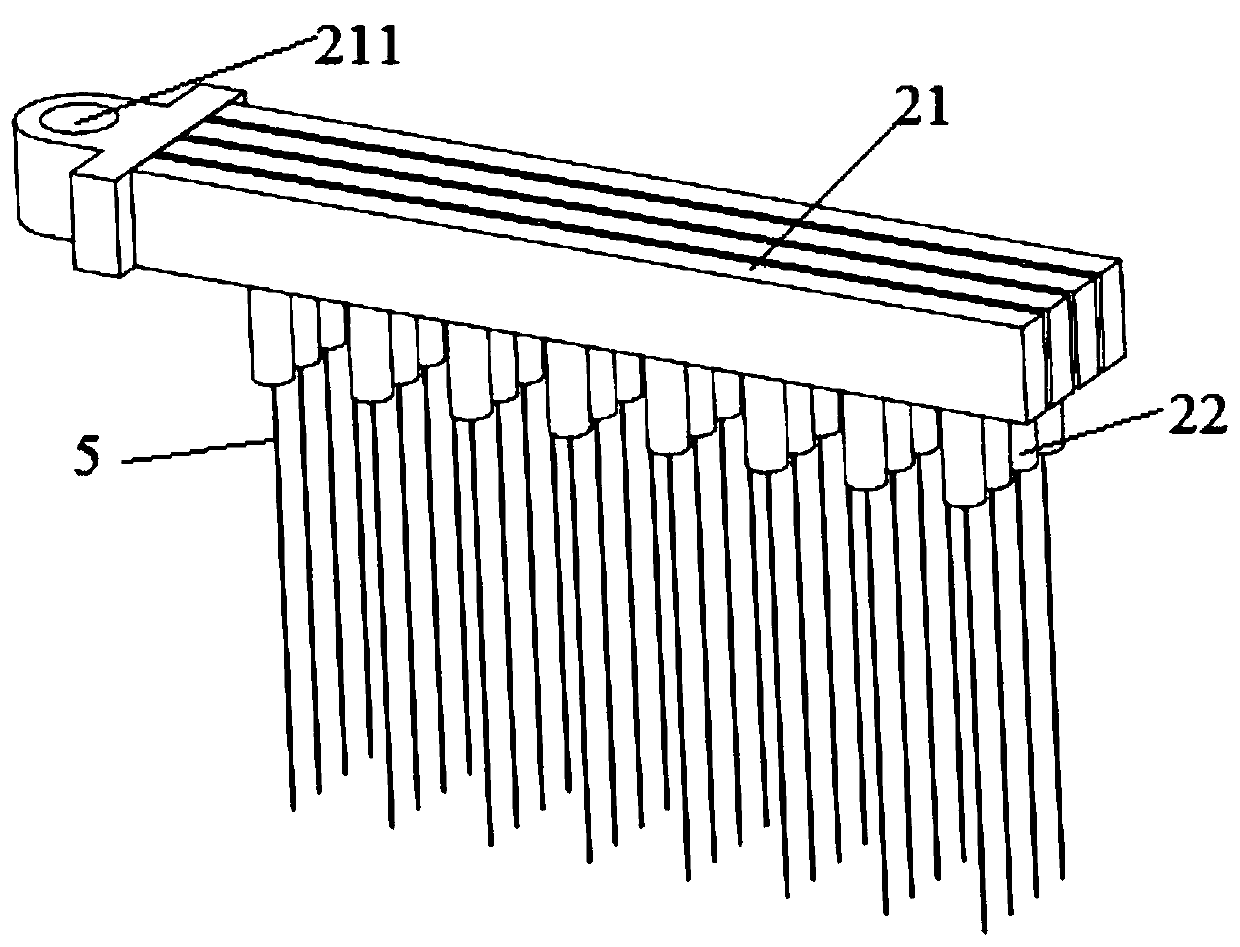

[0036] refer to Figure 1-7 , a batch preparation device for STM probes provided by an embodiment of the present invention, including a mounting base 1, a metal rod assembly 2, a metal ring assembly 3, and a liquid replenishment assembly 4, and the metal rod assembly 2, the metal ring assembly 3, and the liquid replenishment assembly 4 are all Set on the installation base plate 1. The distance between the metal ring assembly 3 and the liquid replenishment assembly 4 relative to the metal rod assembly 2 is adjustable, so that after the probe is prepared by electrochemical corrosion at the lower end of the metal rod fixed in the metal rod assembly 2, the metal ring assembly 3 and the liquid replenishment assembly can be placed Component 4 approaches the metal rod component 2, and continues to prepare probes through electrochemical corrosion on the metal rod, so that multiple probes can be prepared for each metal rod by only adjusting the metal ring component 3 and the liquid rep...

Embodiment 2

[0049] Basically the same as embodiment 1, the difference is:

[0050] This embodiment also provides a batch preparation method for STM probes, including:

[0051] Prepare 32 metal rods 5. In this embodiment, the size of the metal rods is 0.3 mm in diameter and 100 mm in length. Use sandpaper to remove oxides on the surface of the metal rods, and use acetone to ultrasonically clean the metal rods for 20 minutes. The metal rods are treated before the reaction , to prevent the oxide on the surface of the metal rod from affecting the electrochemical corrosion.

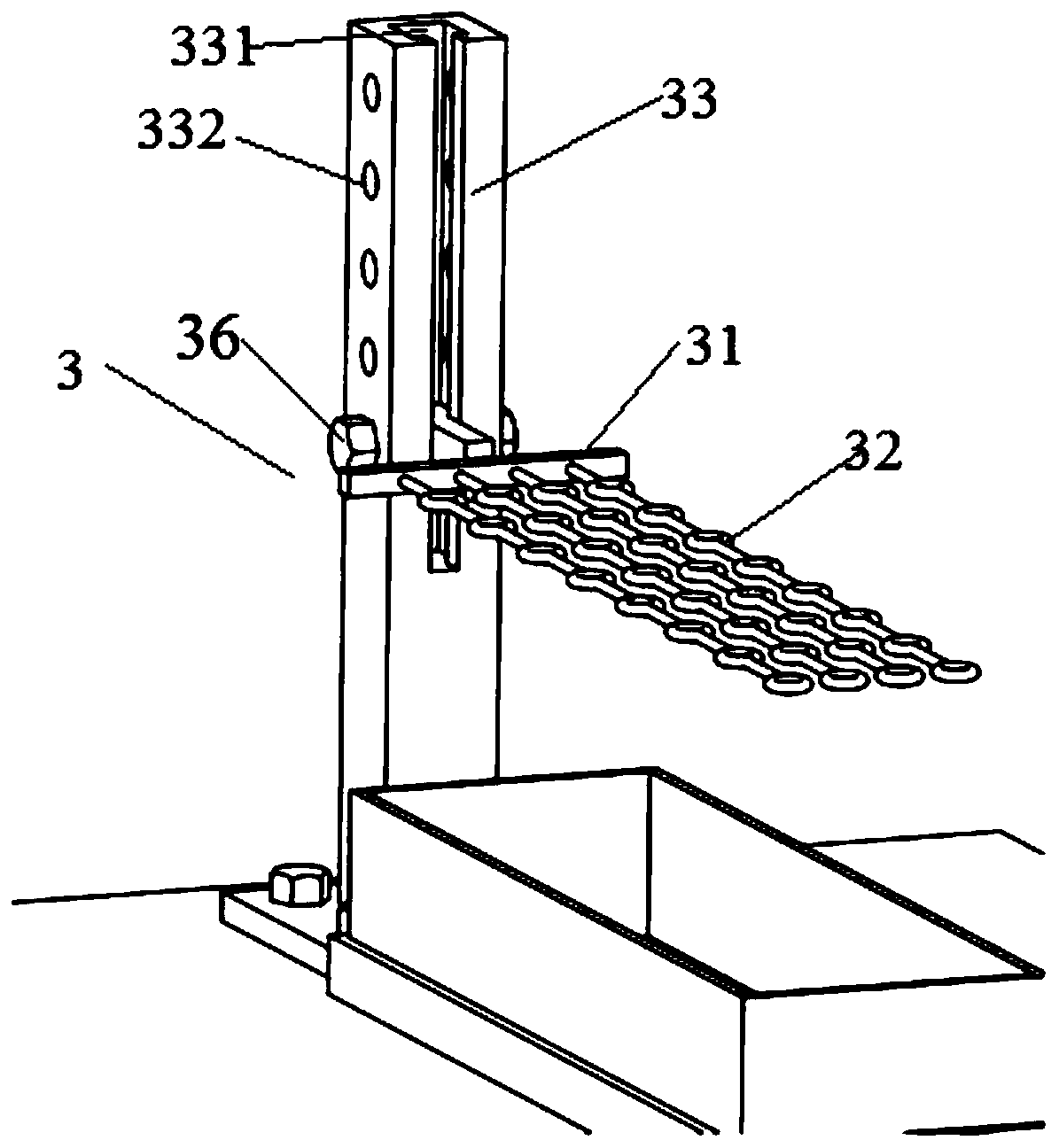

[0052] Put the metal rings 32 in the metal ring assembly 3 into the electrolyte as a whole, so that a liquid film is formed in all the metal rings 32;

[0053] Insert the metal ring slider 34 in the metal ring assembly 2 into the first chute 331, slide the metal ring slider 34 along the first chute 331 to the first positioning hole 332 located at the bottom, adopt the metal ring assembly Fasteners 36 secure the ferrule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com