Multi-gap spark plugs

A spark plug, multi-gap technology, applied in the field of spark plugs, can solve the problems of inability to generate sparks to ignite the mixed gas of the cylinder, inability to break down the spark plugs, and low service life, achieving high reliability, improving service life, and reducing the degree of ablation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

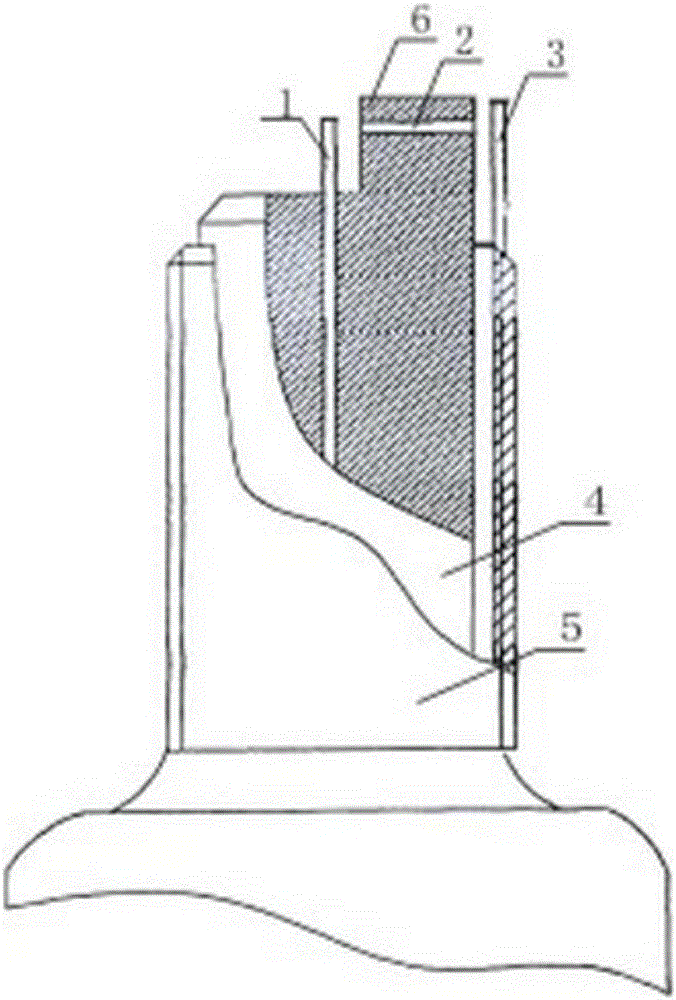

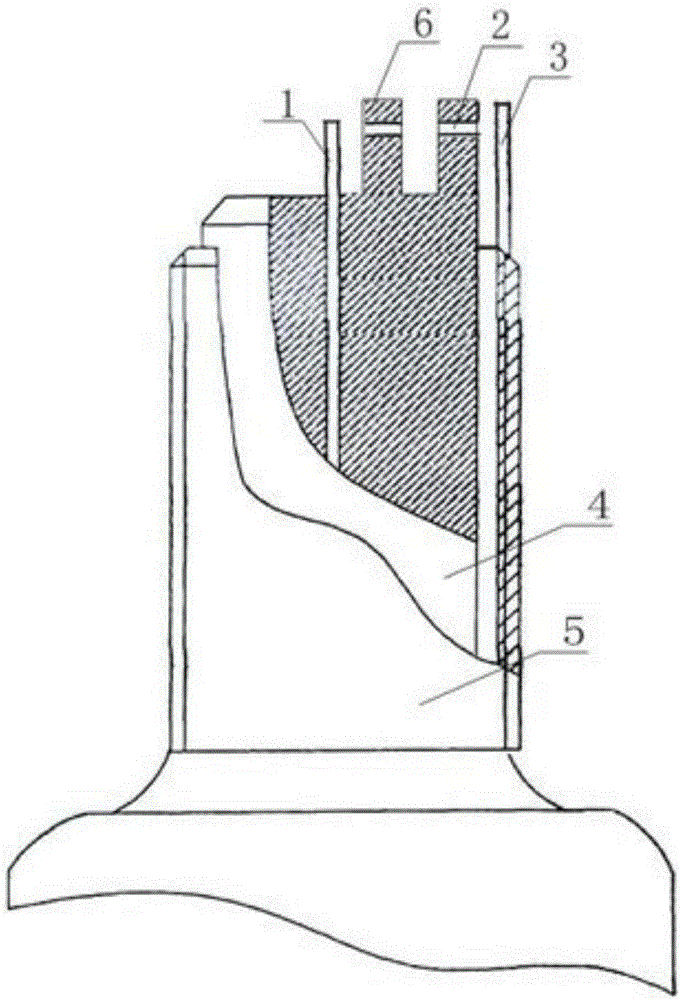

[0019] Such as figure 1 As shown, a multi-gap spark plug of the present invention includes a cylindrical metal shell 5 and an insulating ceramic core 4 arranged in the metal shell 5. The side electrode 3 is provided with a main electrode 1 arranged in the same direction as the axial direction of the insulating ceramic core 4 in the insulating ceramic core 4, and the main electrode 1 and the side electrode 3 are parallel to each other. A guide electrode 2 is arranged between the main electrode 1 and the side electrode 3, and the guide electrode 2 is arranged laterally on the boss 6 protruding upwards of the insulating ceramic core 4, and the two ends of the guide electrode 2 are exposed outside the boss 6, and the guide electrode 2 The axis of the electrode 2 is perpendicular to the main electrode 1 and the side electrode 3 . The main electrode 1 , the guide electrode 2 and the side electrode 3 are arranged in parallel, all in the same plane.

[0020] The upper end face of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com