Method for making full linen lining collar of high-grade men's suit

A production method and technology of hemp lining, which are applied to clothing, tools for sewing clothes, clothing, etc., can solve the problems of non-compliant and round collars, poor air permeability, easy wrinkling and deformation, etc., and achieve a natural, crisp and elastic appearance. Good recovery, not easy to wrinkle and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

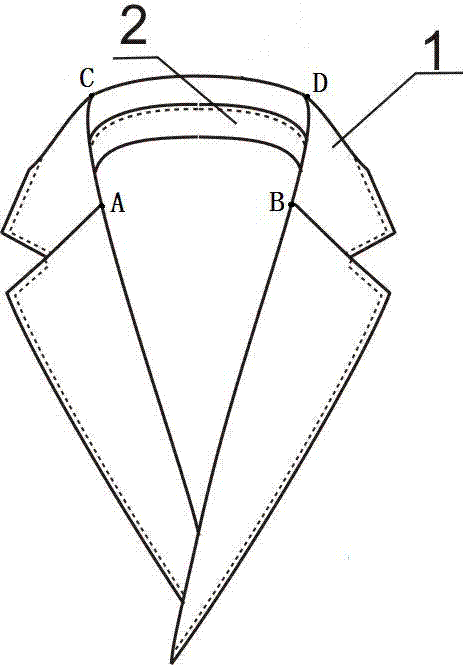

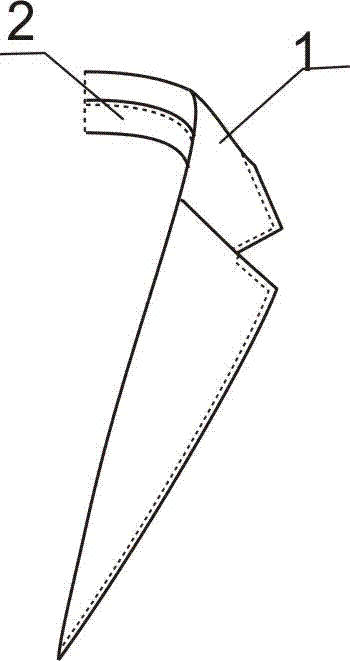

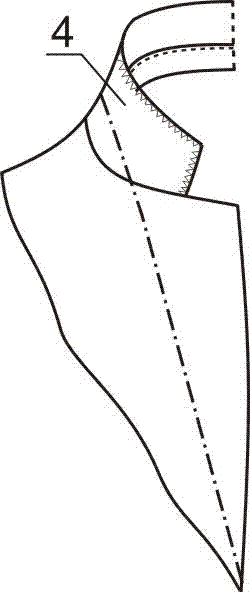

[0020] as attached figure 1 , 2 , 3 and 4, the present invention comprises a lapel surface 1, a sitting collar surface 2, a collar bottom fabric 4 and a collar core black carbon lining 3, and is produced by the following process steps:

[0021] 1. Put the collar core black carbon lining 3 in a steaming box, steam it with steam at 110-120°C for 12-16 hours, take it out, cool it naturally, and dry it to stabilize the elasticity of the collar core black carbon lining , to match the shrinkage rate of the collar, and the steaming box is an ordinary steaming box;

[0022] 2. The lapel surface 1 and the sitting collar surface 2 are humidified with a humidifier for 30 minutes and taken out to dry naturally; the collar fabric will not deform the collar due to dry and wet weather after wearing; the humidifier is Midea KS8U_06N humidifier device;

[0023] 3. Sew the collar bottom fabric 4 and the collar core black carbon lining 3 with hand stitches 5, the manual stitches 5 are wave st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com