Automatic-leveling 3D printer and printing method thereof

A 3D printer, automatic leveling technology, applied in the field of 3D printing, to achieve rapid calibration work, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

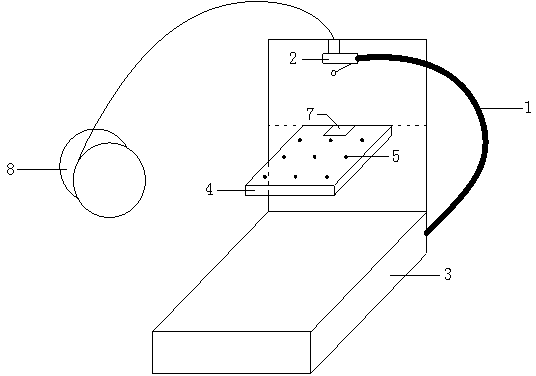

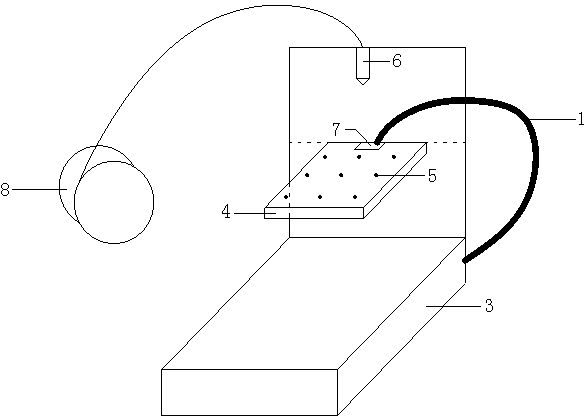

[0021] The technical solution of the present invention will be described below in conjunction with the accompanying drawings. Apparently, the accompanying drawings describe only a part of the present invention rather than all embodiments.

[0022] Such as figure 1 As shown, a self-leveling 3D printer provided by the present invention includes a base 3 on which a mobile bracket 9 is fixed, and the mobile bracket 9 is connected with a nozzle 6 and a working platform 4, and the nozzle 6 is located above the working platform 4 , a plurality of calibration points 5 are evenly distributed on the working platform 4, a horizontal calibrator 2 is fixed on the nozzle 6, and the horizontal calibrator 2 is used to measure the vertical distance between it and the calibration points 5, and the horizontal calibrator 2 is fixed by measuring The relative height positions between the initial point and each calibration point 5 determine the levelness between each calibration point 5 . The horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com