Projection Heat Press Device

A projection type, substrate technology, used in printing, rotary printing presses, printing presses, etc., can solve the problems of wasting heat and destroying the original performance of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

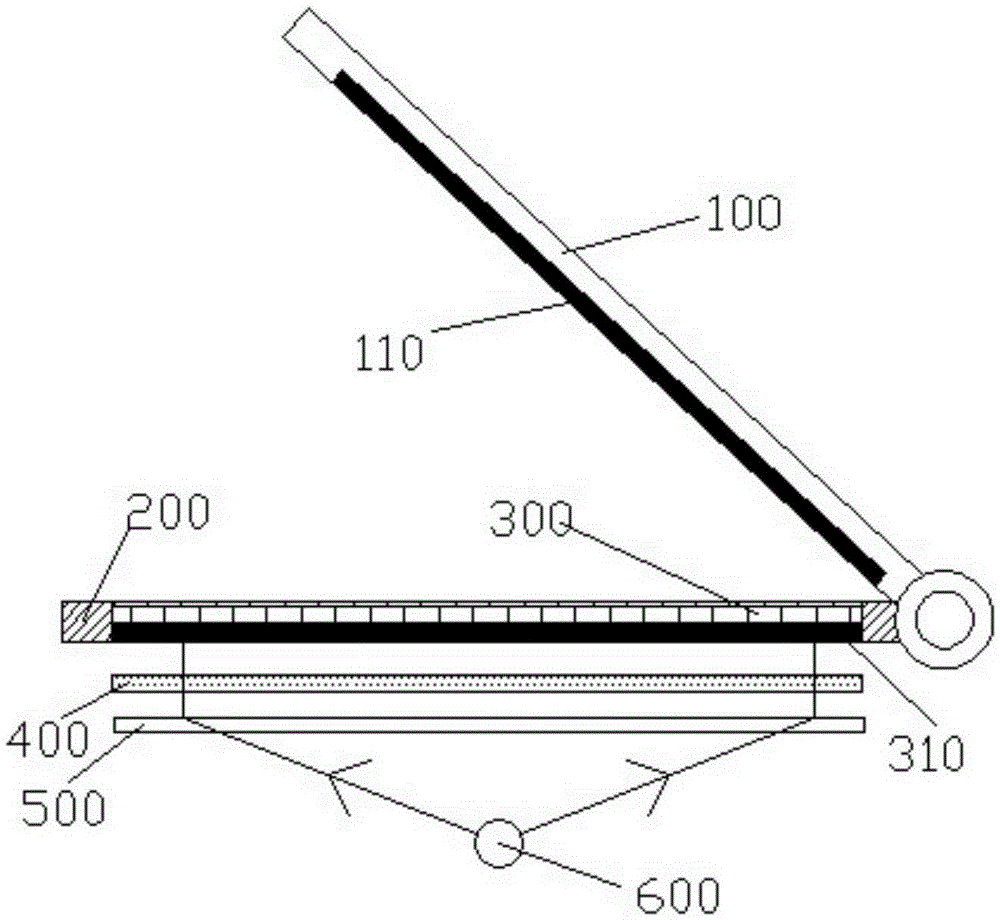

[0015] In this example, see figure 1 , the projection type heat press device includes a first substrate 100 and a second substrate 200 that cooperate with each other, the first substrate 100 is provided with a heat conducting plate 110 with a heater, and the second substrate 200 includes a frame surrounded A transparent substrate 310 and a temperature-sensitive film 300 whose thickness is controlled by temperature, the temperature-sensitive film 300 is arranged on the transparent substrate 310, and a liquid crystal panel 400, a condenser lens 500 and a light source 600 are sequentially arranged below the transparent substrate 310 .

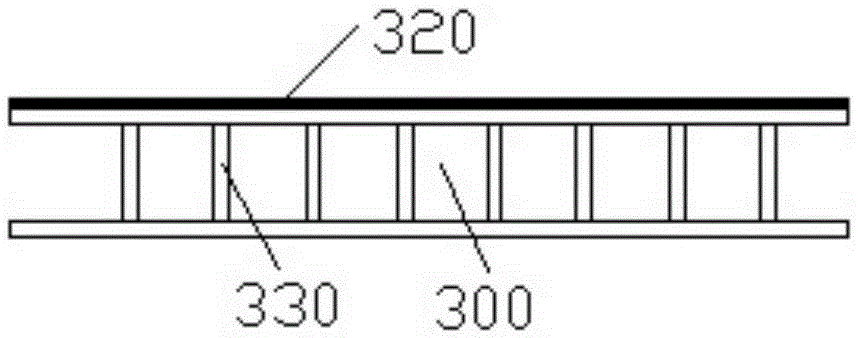

[0016] refer to figure 2 , the temperature-sensitive film 300 is composed of a double-layer film, and a closed chamber is uniformly laid in the double-layer film, and a heat insulating layer 330 is arranged between the closed chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com