A kind of torsion cylinder assembly in the middle part of mining dump truck

A torsion cylinder and assembly technology, which is applied in the direction of vehicles with tilted bearing movement, can solve the problems that the coaxiality is difficult to meet the design requirements, reduce the reliability of the middle torsion cylinder, and reduce the overall life of the frame, so as to improve the rigidity and improve the Reliability, the effect of overcoming stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

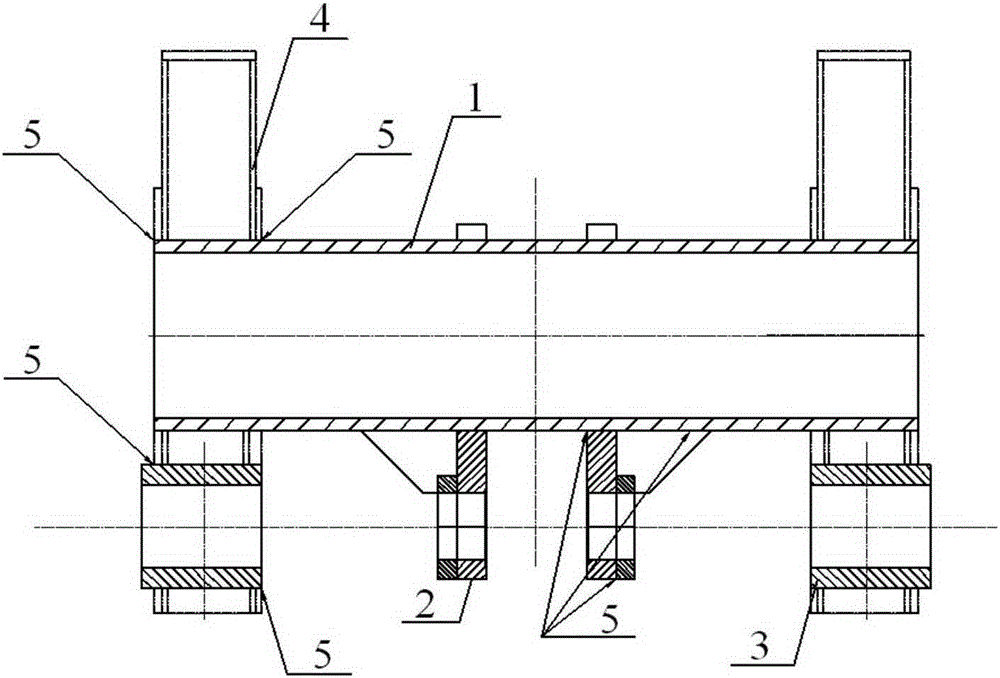

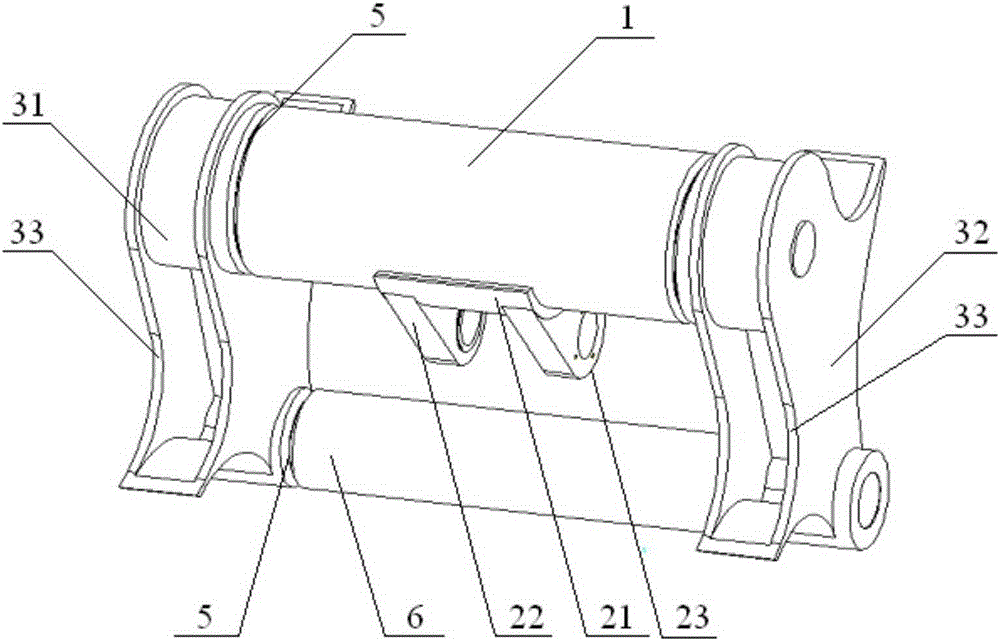

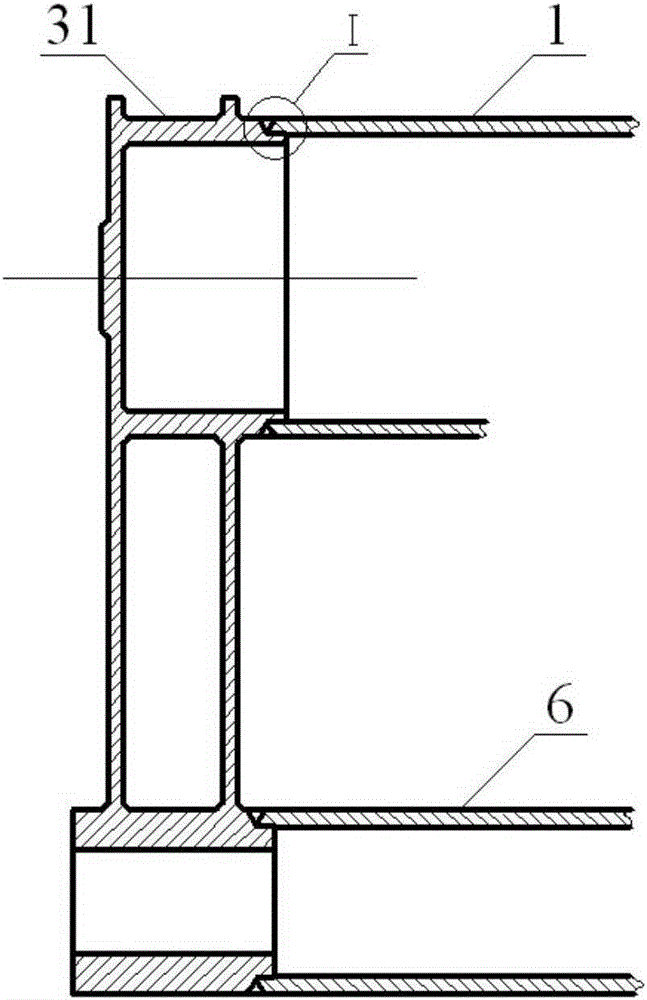

[0032] like figure 2 As shown, the middle torque tube assembly of the mine dump truck in this embodiment includes a torque tube 1 , a thrust frame, a lift cylinder support and a lift cylinder shaft sleeve 6 .

[0033] The lift cylinder support of this embodiment includes a left support 31 and a right support 32, and the lift cylinder shaft holes are respectively arranged opposite to each other on the left support 31 and the right support 32, which are arranged on the lift cylinder shaft. The corresponding position is used to fix the lift cylinder shaft. On the left support 31 and the right support 32, there are respectively opposite torsion cylinder shaft holes, which are located above the lift cylinder shaft holes, and are used to fix the torque cylinder 1. The torque cylinder 1 of this embodiment The two ends are sheathed in the shaft holes of the torque cylinder of the left support 31 and the right support 32 respectively.

[0034] In this embodiment, the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com