Step walking trolley

A walking trolley and ladder technology, which can be applied to trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of waste of manpower and material resources, high work intensity, damage to goods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

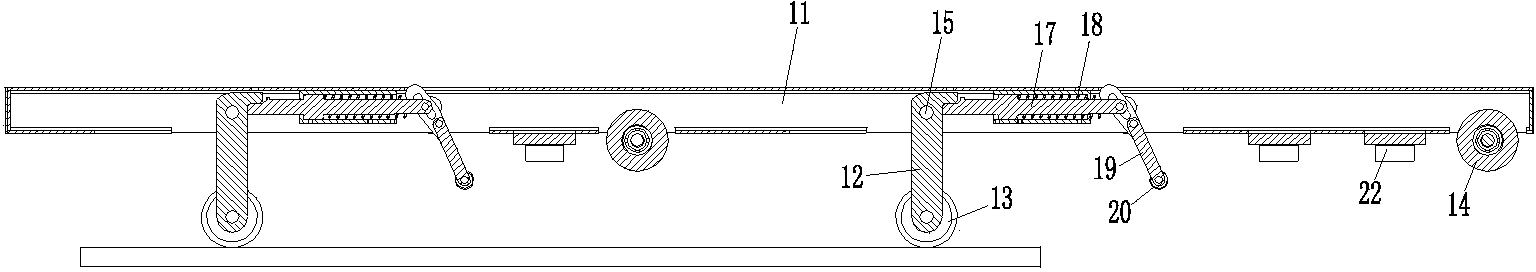

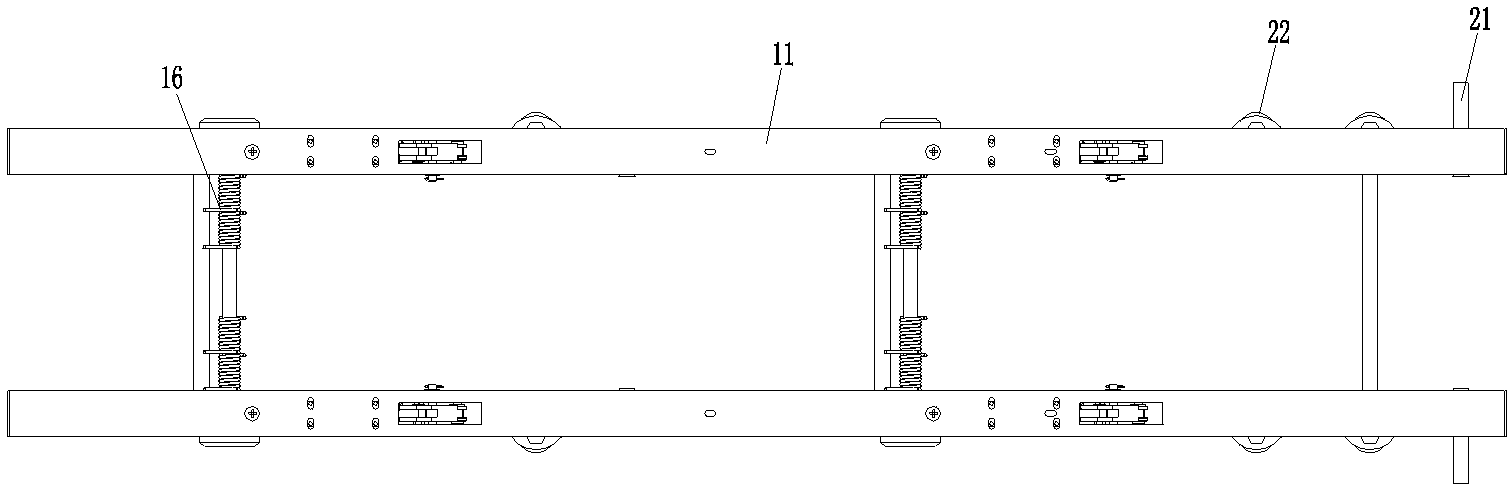

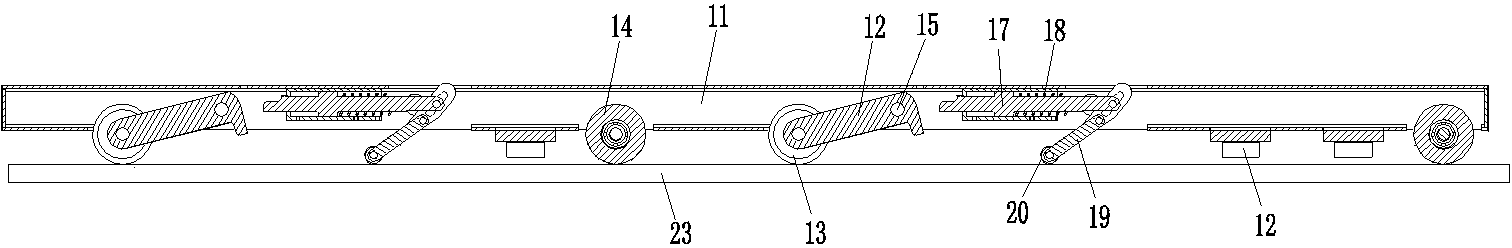

[0018] An embodiment of a ladder walking trolley, such as Figure 1-3 As shown, the ladder walking dolly includes a vehicle frame 11 and traveling wheels.

[0019] The vehicle frame 11 is rectangular and is a frame structure. The walking wheels include two pairs of folding casters 13 and two pairs of fixed height casters 14 assembled on the vehicle frame 11 through the folding wheel frame 12. The arrangement order of the folding casters 13 and the fixed height casters 14 is as follows from front to back: fixed height casters— Folding casters - fixed height casters - folding casters.

[0020] The height-fixing caster 14 directly rotates and is assembled on the vehicle frame 11, and its axis of rotation extends along the left-right direction. Folding caster 13 is assembled on the vehicle frame 11 by corresponding folding wheel frame 12 and its axis of rotation is parallel to the axis of rotation of fixed-height caster 14; Parallel to the rotation axis of the folding caster 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com