Cold accumulation type refrigerated transporting system and refrigerating method

A transportation system and cold storage technology, which is applied in the direction of transporting passenger cars, tank cars, railway car body parts, etc., can solve the problems of large area of cold storage strips, low heat exchange efficiency, long charging time, etc., and achieve good heat exchange effect and full charge Cooling time is short and the effect of reducing cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings of the description.

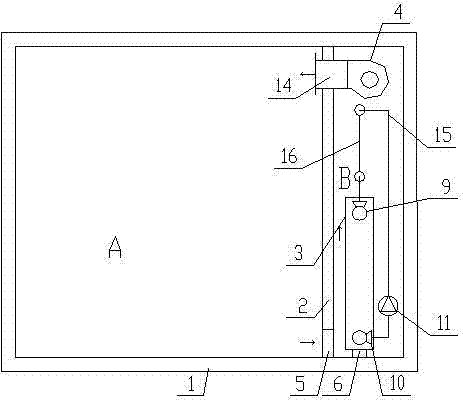

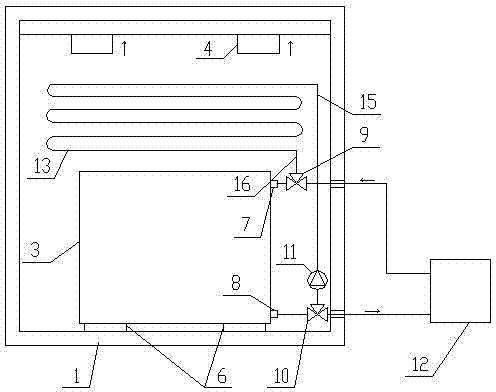

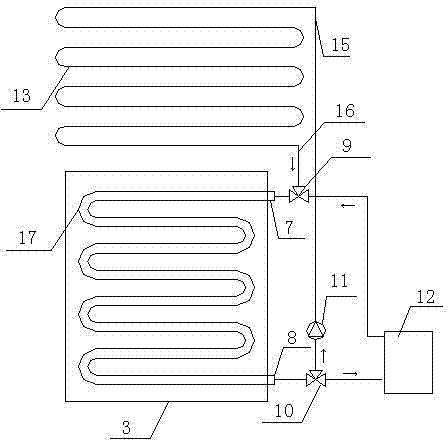

[0023] Such as figure 1 , 2 As shown, a cold storage type refrigerated transportation system includes an insulated box 1 with a parallelepiped structure, and a partition 2 is arranged inside the insulated box 1, and the partition 2 divides the inner space of the insulated box 1 into The larger refrigerating chamber A and the smaller cold storage chamber B, the cold storage chamber B is specifically located between the partition plate 2 and the end wall of the heat preservation box 1 . The cold storage chamber B is provided with a cold plate 3 , a circulating fan 4 and an external coil 13 . The upper end of the partition 2 is provided with two air outlet holes 14, and the lower end is provided with two air inlet holes 5. The above-mentioned circulation fan 4 is fixed on the top wall of the box, and the input end of the circulation fan 4 faces downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com