A cold storage plate and a cold storage method thereof

A cold-storage plate and cold-storage technology, which can be applied to tank trucks, packaging items, special packaging, etc., can solve the problems of cold-storage or refrigerant leakage, cargo contamination, and long cooling time, so as to reduce cooling costs and cooling time. Short, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings.

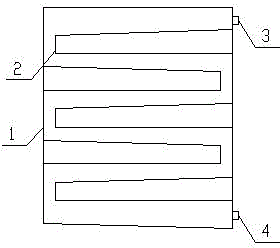

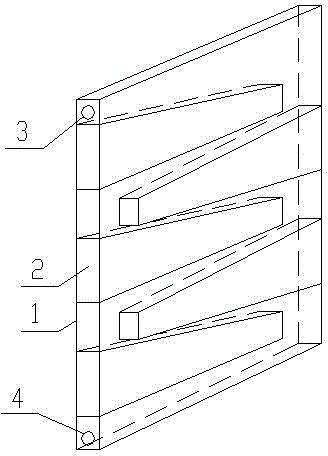

[0025] like figure 1 , 2 As shown, a cold storage plate, the cold storage plate 1 is a hollow metal plate, which includes left and right side surfaces, upper and lower bottom surfaces, and two side end surfaces. The cold storage board 1 can be used in refrigerated transport vehicles, refrigerated railway trucks and refrigerated containers for refrigerating goods.

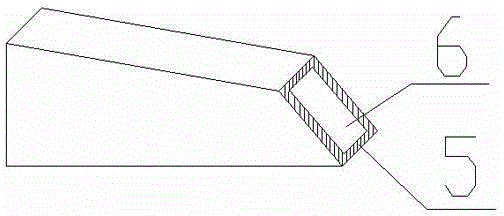

[0026] like figure 1 , 2 As shown, the cold storage plate 1 is provided with a plurality of cold storage bars 2 arranged in parallel up and down. One end face is connected to the cool storage plate 1 respectively, and the end faces of adjacent cool storage bars 2 are connected to different end faces of the cool storage plate 1 side. Since the upper surface, lower surface and one end surface of the cool storage bars 2 are in contact with the cool storage plates 1, a gap is formed between the adjacent cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com