Brake machine for belt conveyor in coal mine roadway

A technology of belt conveyor and coal mine roadway, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of belt conveyor equipment damage, many loading points, and coal mine production cannot be carried out normally. The effect of speeding, avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

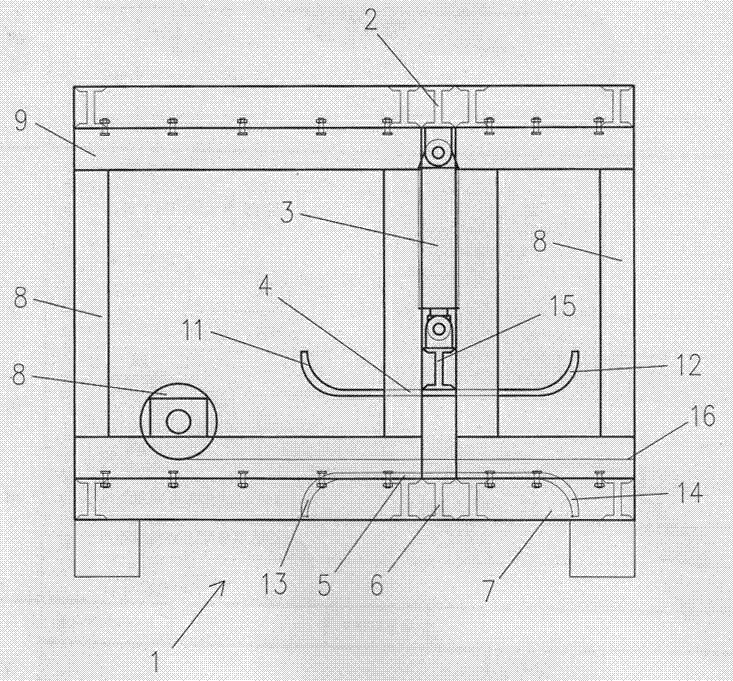

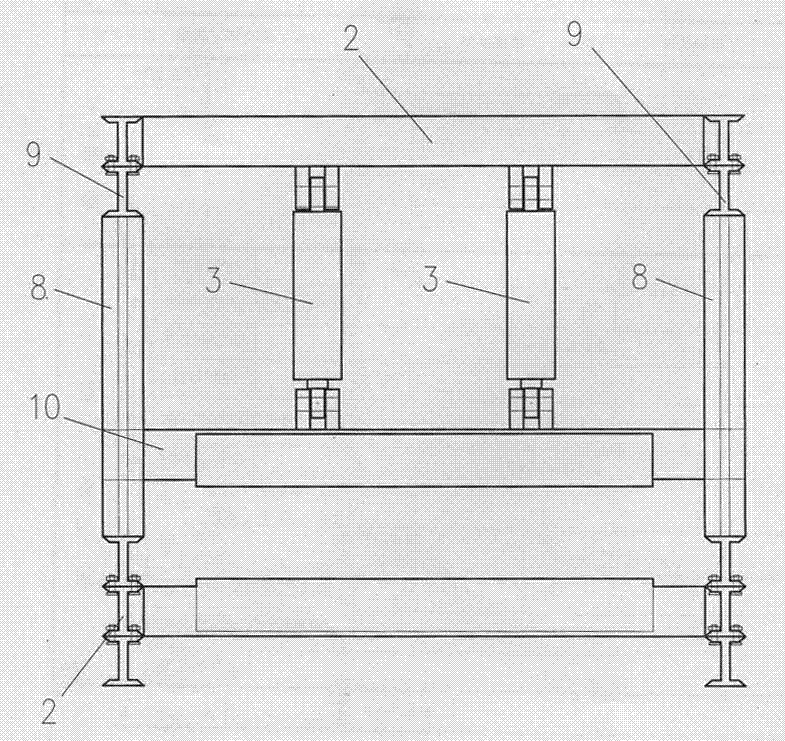

[0013] Such as figure 1 and figure 2 As shown, the belt conveyor gate in the coal mine roadway of the present invention includes a frame 1, the top of the frame 1 is provided with a top beam 2 along the front and rear horizontal directions, and a plurality of jacks or oil cylinders 3 are provided below the top beam 2, The axis of the jack or oil cylinder 3 is in the vertical direction, the base of the cylinder body of each jack or oil cylinder 3 is hingedly connected with the lower end of the beam 2 respectively, and the piston rod of each jack or oil cylinder 3 is fixedly connected with the top of the upper belt splint 4 respectively , the plate surface of the upper belt splint 4 is located in the horizontal direction, and the bottom end of the upper belt splint 4 is fixed with an upper flexible pad (not shown in the figure); The board surface is located in the horizontal direction, and the top of the lower belt splint 5 is fixed with a lower flexible pad (not shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com