Crane control method, controller, and control device

A control method and control device technology, applied to cranes, transportation and packaging, load hanging components, etc., to achieve the effect of improving convenience and increasing the operable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

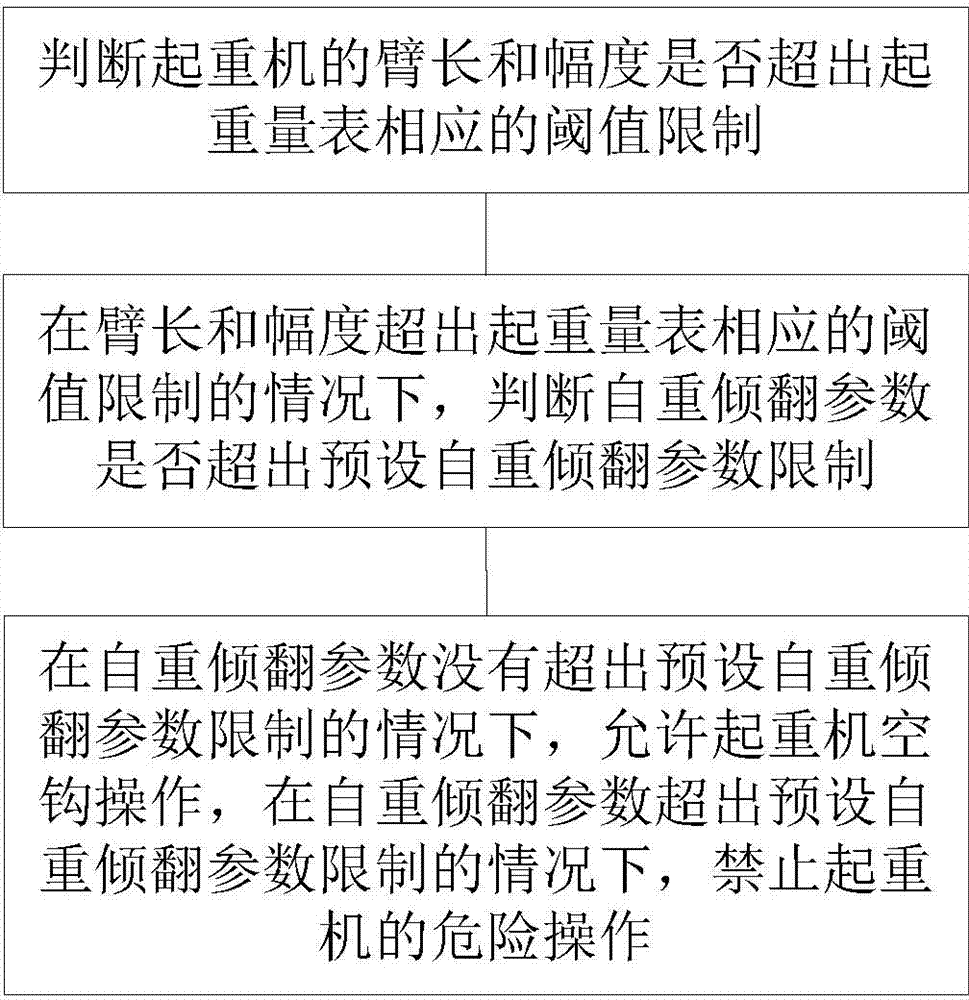

[0021] Such as figure 2 As shown, the crane control method according to the present invention includes the following steps: a first judging step: judging whether the arm length and amplitude of the crane exceed the corresponding threshold limit of the lifting capacity table; second judging step: when the arm length and amplitude exceed the lifting capacity In the case of the corresponding threshold limit in the table, judge whether the self-weight tipping parameter exceeds the preset self-weight tipping parameter limit; control step: when the self-weight tipping parameter does not exceed the preset self-weight tipping parameter limit, allow the crane to operate with an empty hook , when the self-weight tipping parameter exceeds the preset self-weight tipping parameter limit, the dangerous operation of the crane is prohibited; wherein, the dangerous operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com