Waste heat electricity-water cogeneration device and method for diesel power station in sea island

A technology for power stations and islands, which is applied to waste heat, electricity and water cogeneration devices and fields of island diesel power stations, which can solve the problems that people cannot live for a long time, and achieve the effect of reducing temperature and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

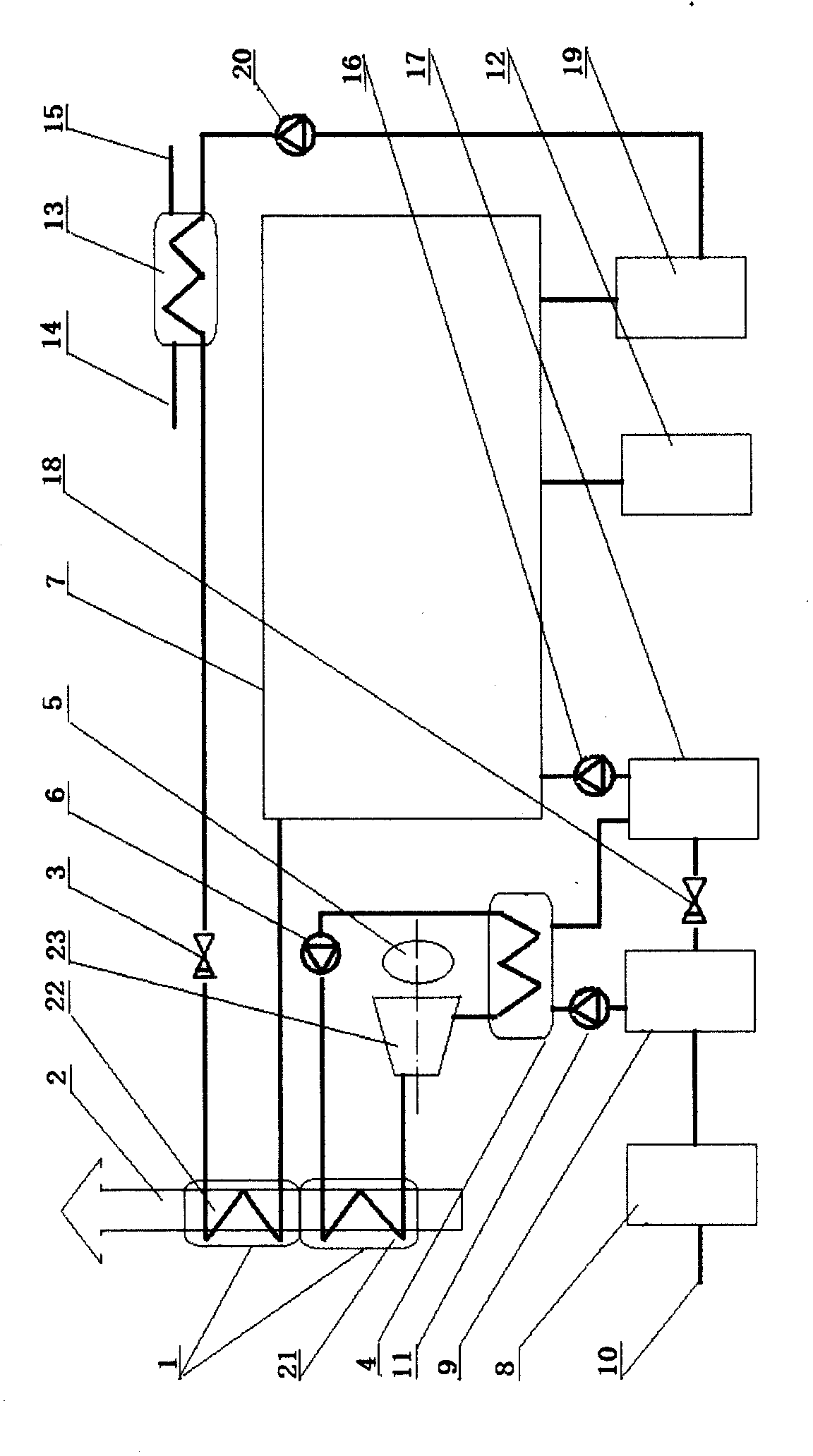

[0032] Example 1: Using an evaporative seawater desalinator

[0033] see figure 1 , The combined waste heat boiler 1 is installed on the exhaust channel 2 of the internal combustion engine of the island diesel power station, divided into two parts, a high temperature section and a low temperature section. The temperature of the high temperature section reaches 400-450 o C, low temperature section temperature 200-250 o C. The working medium evaporator 21 of the ORC power generation system is set on the high temperature section, and the steam generator 22 is set on the low temperature section. The working fluid evaporator obtains heat from the exhaust gas of the internal combustion engine, adjusts the working fluid booster pump 6 to evaporate the organic working fluid to a critical or supercritical state, and sends it to the turbo expander 23 to perform work, which drives the coaxial generator 5 to send out electricity. The exhaust gas of the organic working medium discharged from ...

Embodiment 2

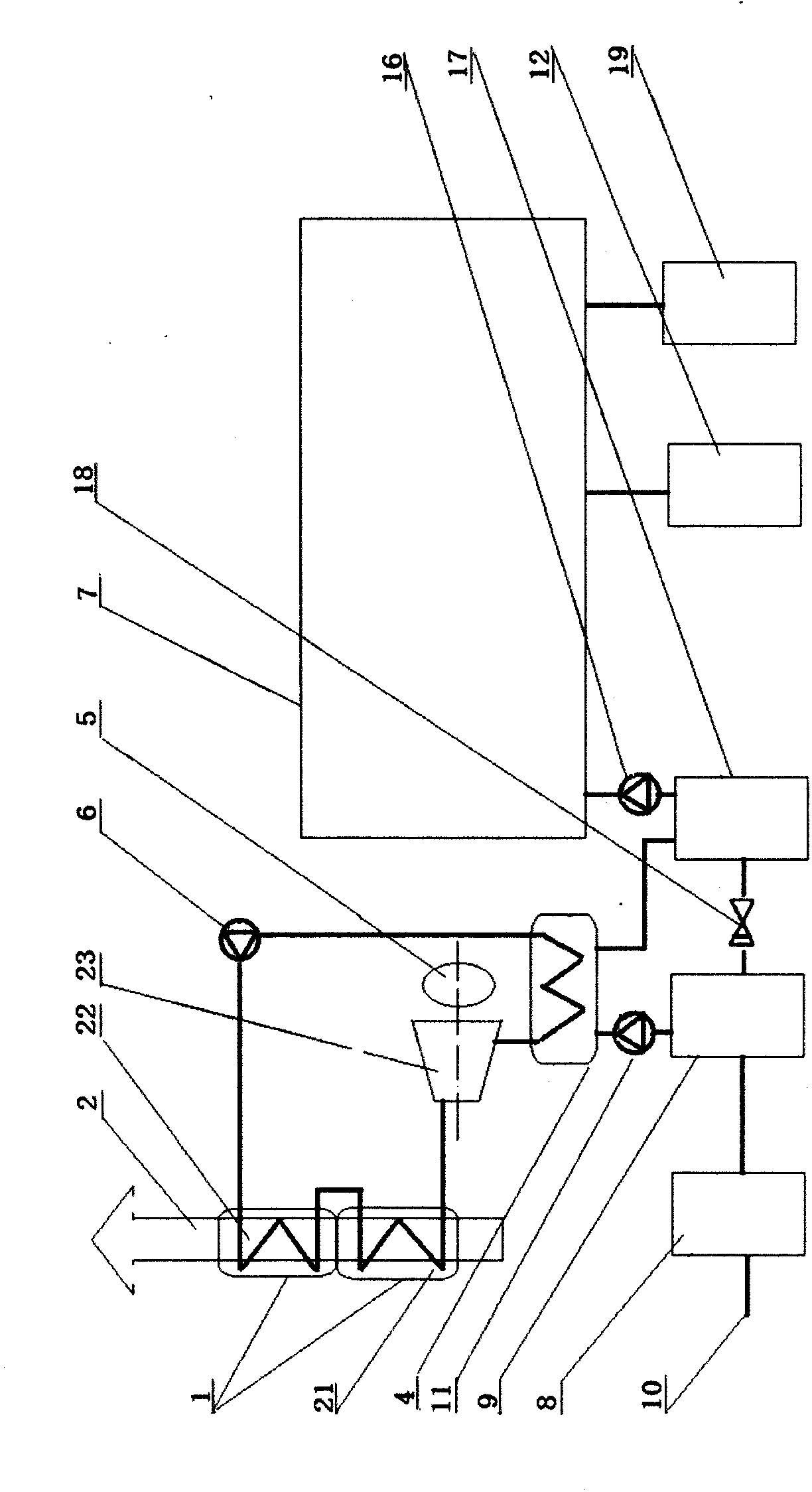

[0036] Example 2: Using reverse osmosis membrane type seawater desalinator

[0037] see figure 2 , The combined waste heat boiler 1 is installed on the exhaust channel 2 of the internal combustion engine of the island diesel power station, divided into two parts, a high temperature section and a low temperature section. The temperature of the high temperature section reaches 400-450 o C, low temperature section temperature 200-250 o C, an evaporator 22 is provided on the low temperature section. A superheater 21 is provided on the high temperature section. The organic working fluid is pressurized and sent to the evaporator 22 by the working fluid booster pump 6, and then sent to the superheater 21 after evaporation, reaching a critical or supercritical state, and sent to the turbo expander 23 to perform work, which drives the coaxial generator 5 to send out electricity. The exhaust gas of the organic working medium discharged from the turboexpander 23 is sent to the working me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com