Full-automatic closed floor drain

A closed and fully automatic technology, applied in water/sludge/sewage treatment, indoor sanitary piping installations, drainage structures, etc., can solve problems such as difficult operation, slow drainage speed, and deodorization function, so as to reduce labor costs Operation, avoiding leakage, and lasting effect of drainage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

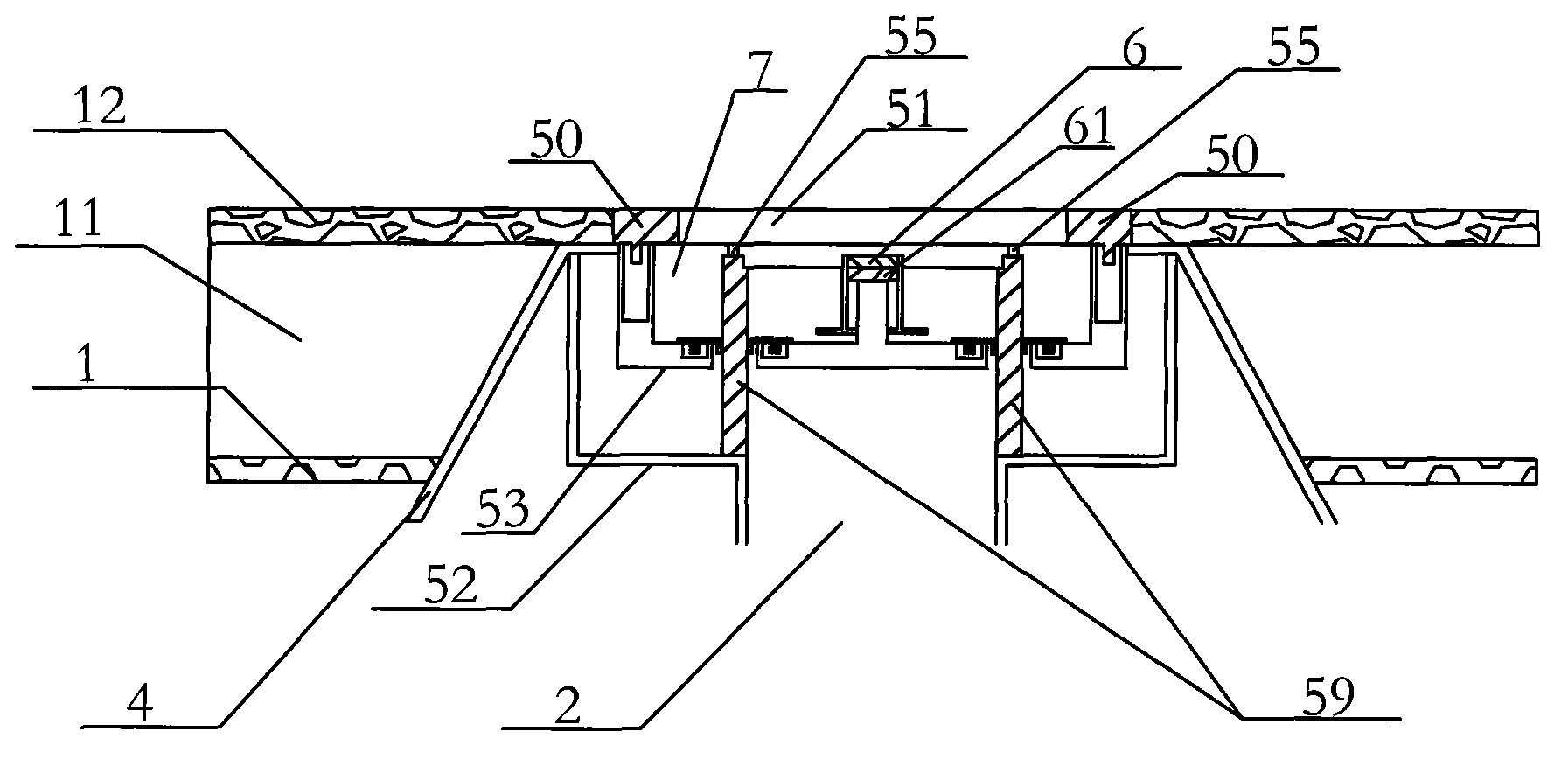

[0030] The following description will be made in conjunction with the accompanying drawings and specific implementation methods, the purpose is for the public to better understand the content, not to limit the content. In fact, the improvement of the floor drain with the same or similar principles , including its shape, size, material used, and the addition, subtraction or replacement of each component, all for the purpose of achieving basically the same effect, are all within the technical solution claimed by the present invention.

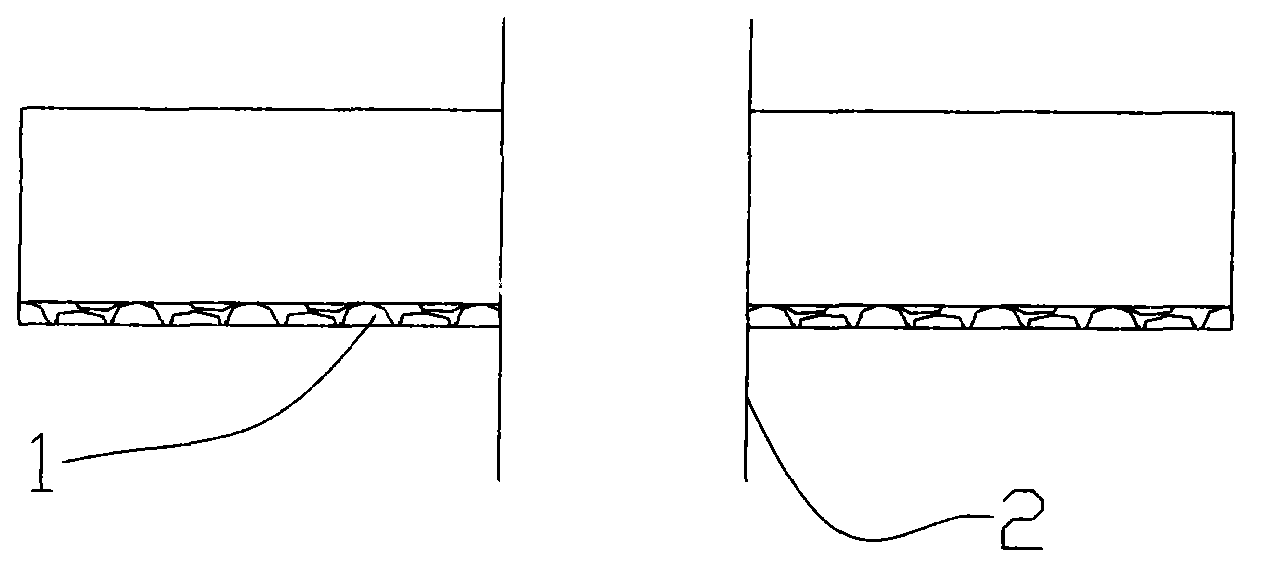

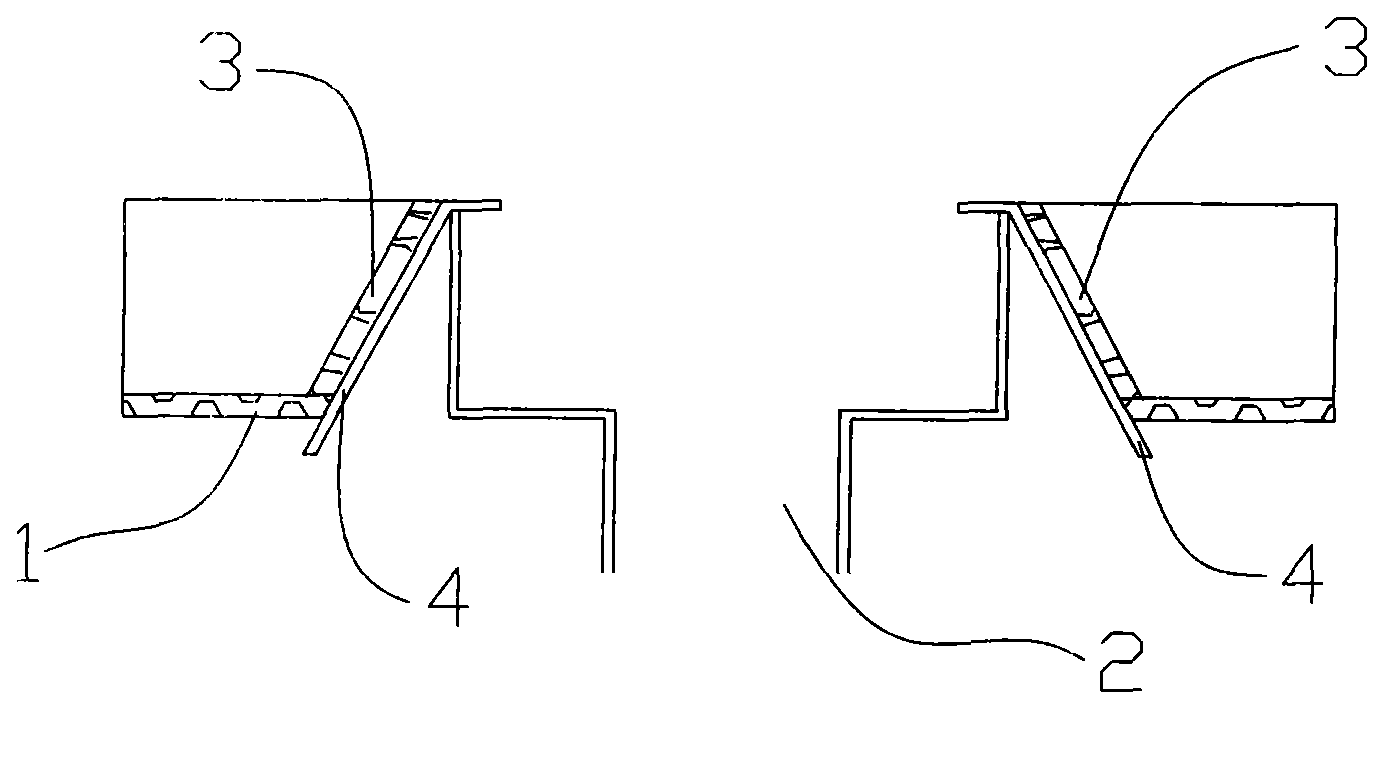

[0031] figure 1 It shows the waterproof design of the existing floor drain. As shown in the figure, the sewer pipe 2 is at a vertical angle to the horizontal plane of the ground waterproof layer 1. Since the sewer pipe 2 is perpendicular to the ground, it is not easy to operate when brushing the waterproof layer. When brushing the waterproof layer, it is often The protection of the waterproof layer is not comprehensive, so that water leaks from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com