Pneumatic slag discharge valve with continuous automatic opening and closing

A technology for automatic opening and closing and slag discharge valves, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of being unable to discharge molten ash, inconvenient detection, and the inability to realize automatic opening and closing of valves, etc., to achieve Improve overall reliability, facilitate processing and installation, and effectively control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

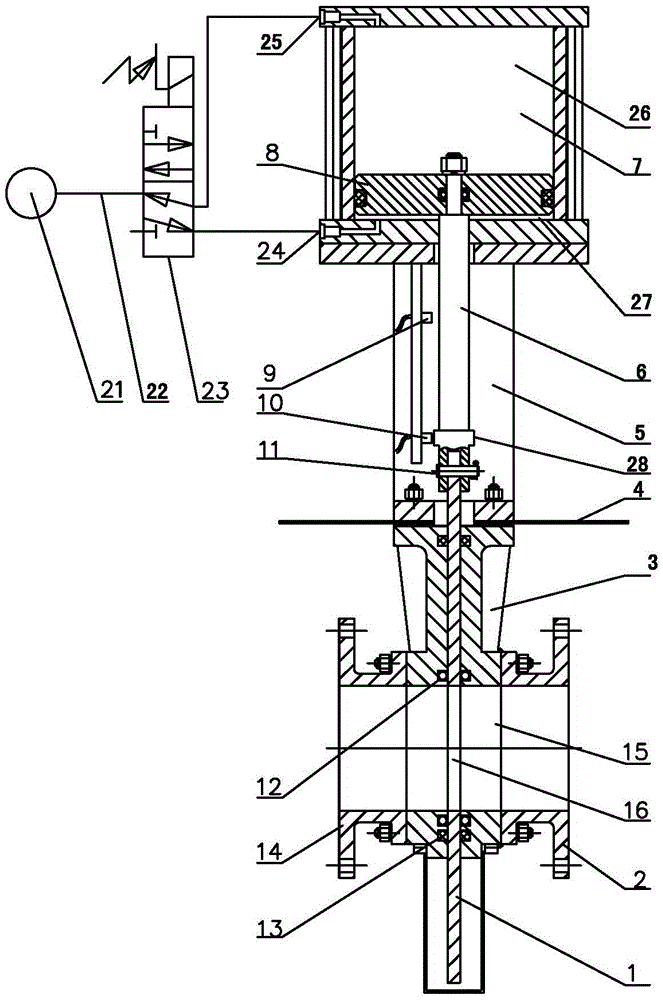

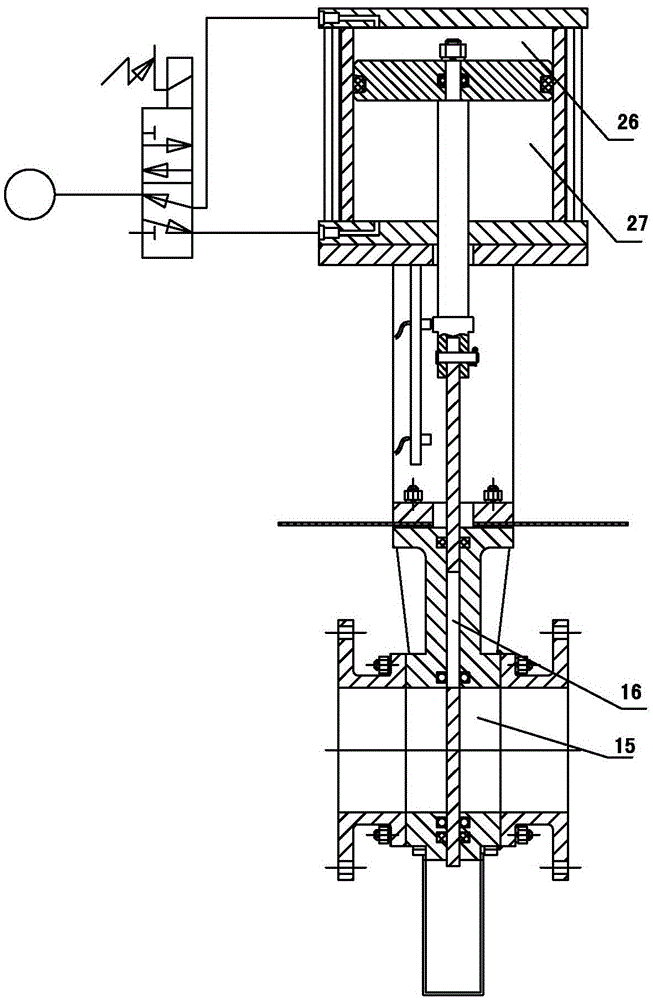

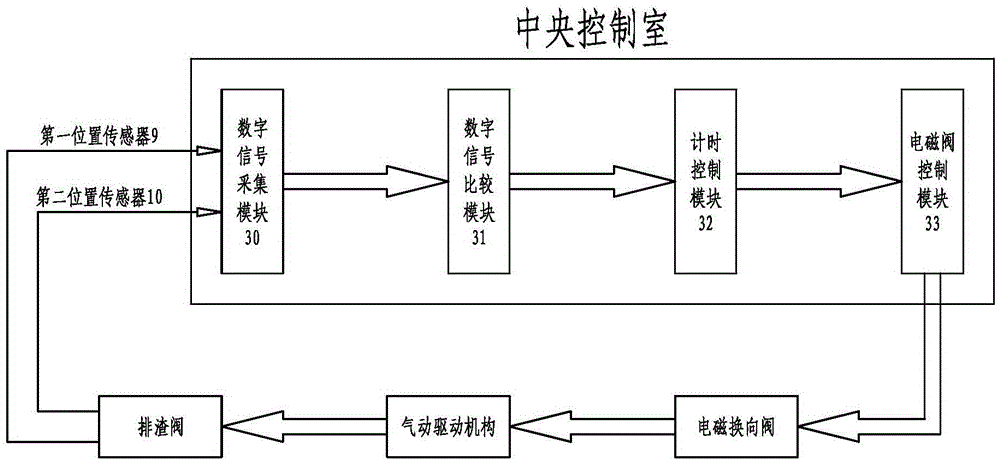

[0027] as attached figure 1 As shown, a pneumatic slag discharge valve that can be continuously and automatically opened and closed includes a slag discharge valve, a drive mechanism, a position sensor unit and a central control room. The slag discharge valve and the drive mechanism are connected together through a bracket 5. Including gate 1, valve body 3, hollow metal O-ring 12, and sealing packing 13, valve body 3 is provided with a slag discharge channel, and the gate 1 moves to realize opening and closing of the slag discharge channel in valve body 3. The driving mechanism controls the opening and closing of the slag discharge valve by driving the movement of the gate 1. The position sensor unit is arranged on the bracket, and the central control room is connected with the position sensor unit. The position sensor unit can sense the movement information of the piston rod and send it to the central control unit. Room, the central control room is used to control the action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com