Isolated automatic scenting machine

A scented flower machine and an isolated technology, applied in the field of isolated automatic scented flower machines, can solve the problems of insufficient temperature and humidity control of scented flowers, insufficient automation, etc., and achieve the effects of avoiding sensor failure, saving labor costs, and ensuring accurate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

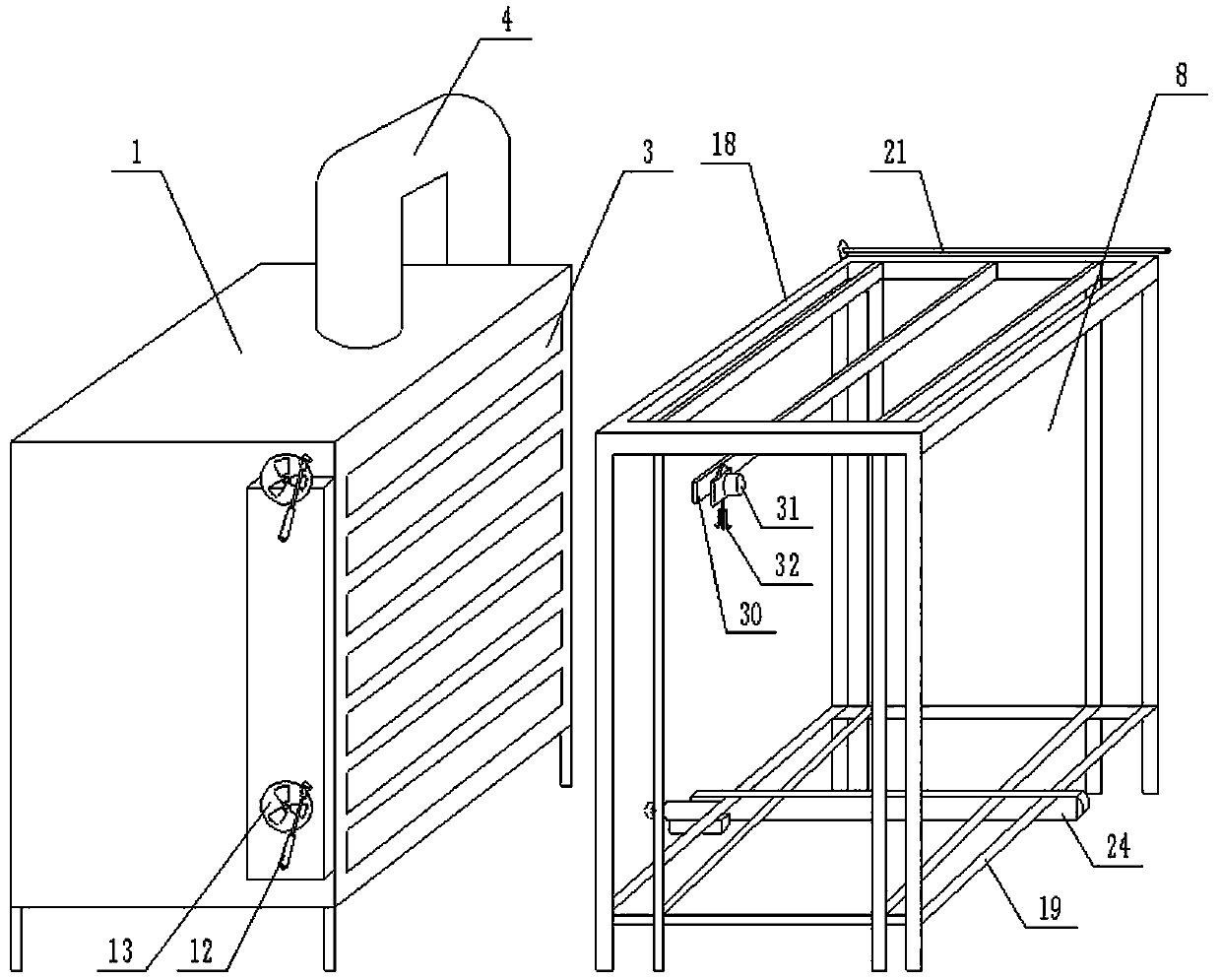

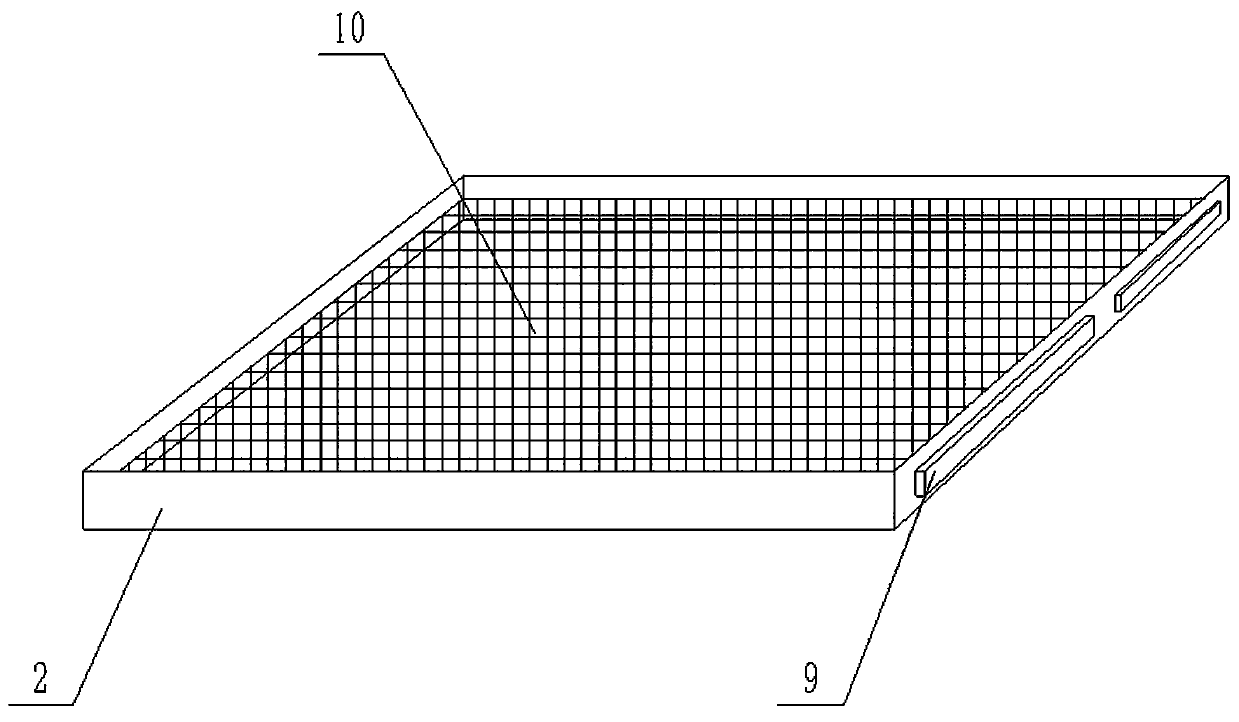

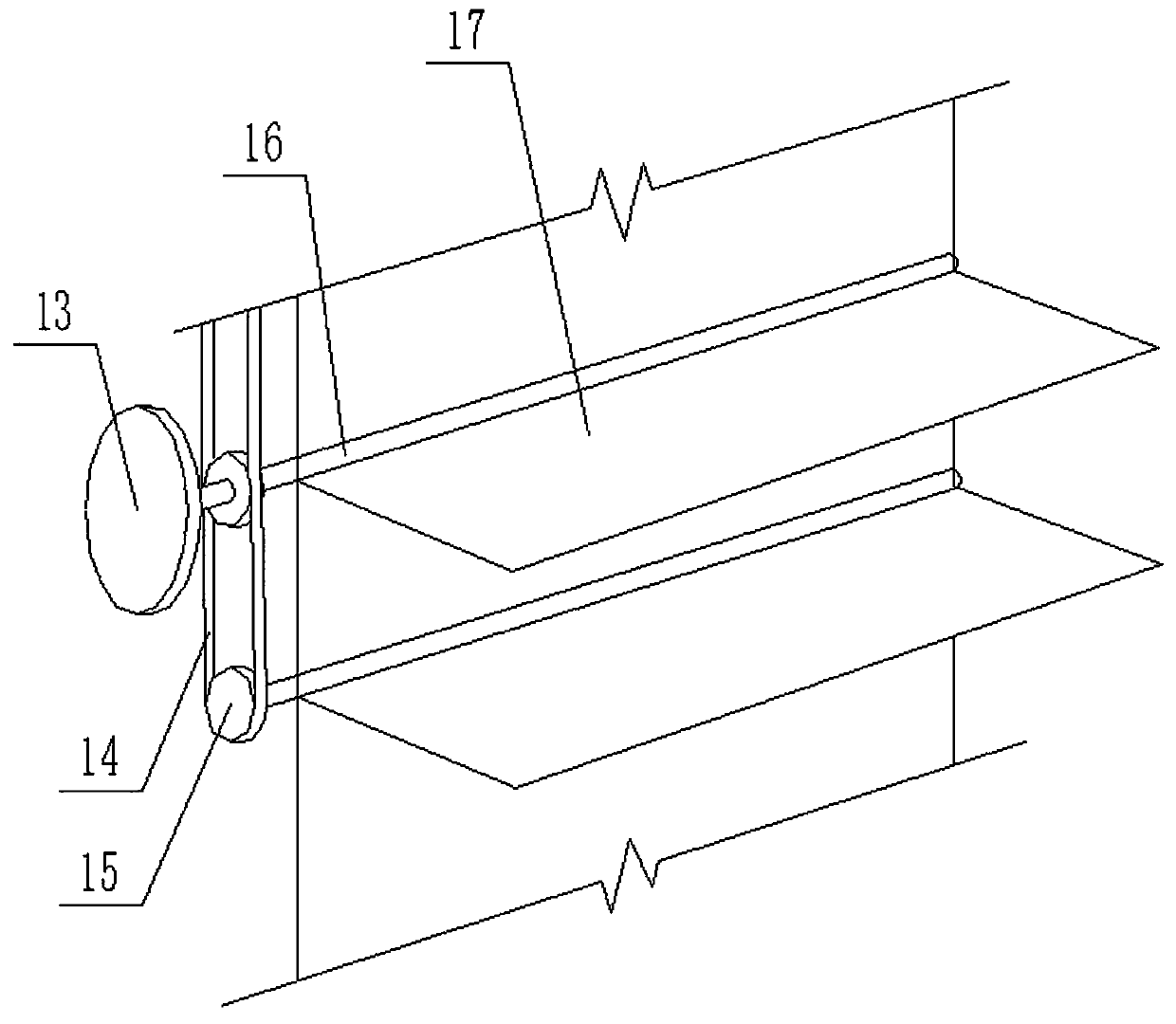

[0031] An isolated automatic scenting machine, comprising: a scenting box 1, a tray 2, a louvered baffle door 3, a circulating air duct 4, an induced draft fan 5, a temperature and humidity sensor 6, a water tank 7 and an automatic feeding and discharging device 8. A plurality of horizontal guide rails are evenly distributed from top to bottom on both sides of the scenting flower box 1, and a plurality of trays 2 are installed on the guide rails from top to bottom. The board corresponds to the position of each tray 2, and the top and bottom of the scenting box 1 are provided with a circulating air duct 4, the circulating air duct 4 communicates with the induced draft fan 5, and the connection between the induced draft fan 5 and the circulating air duct 4 is externally connected to the water tank 7 through a water pipe. A temperature and humidity sensor 6 is provided, and an automatic feeding and discharging device 8 is positioned at the front of the scenting flower box 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com