Open vibration valve with electric proportional control function and pressure compensation function and used for road roller

A technology of pressure compensation and electric proportionality, which is applied in the field of hydraulic system of road rollers, can solve the problems that volumetric efficiency loss compensation cannot be realized, speed regulation function cannot be realized, and vibration system stepless speed regulation cannot be realized, so as to avoid low-speed resonance and good speed Rigidity, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

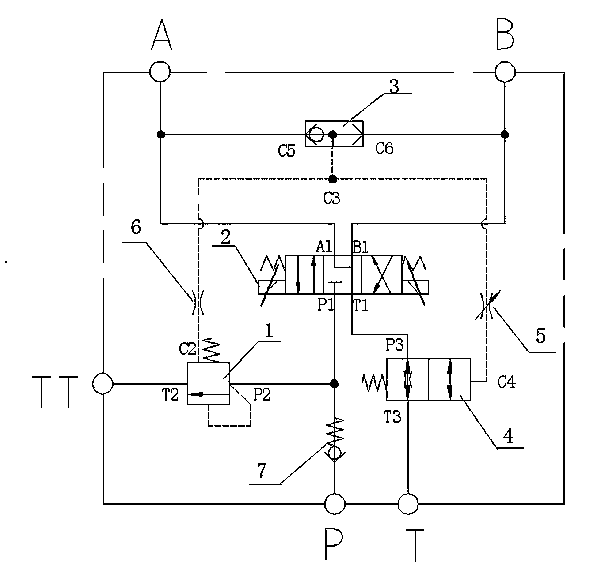

[0023] see figure 1 , the present invention is an electric proportional control and pressure compensation open-type vibrating valve for road rollers. The valve block is provided with a pressure compensation valve 1, a three-position four-way electric proportional valve 2, a shuttle valve 3, a two-position two-way reversing valve 4, Variable throttle valve 5, throttle orifice 6 and one-way valve 7, and five ports P, T, TT, A, B are opened on the valve block, among which P port is the oil inlet port of the valve block, generally connected to The outlet of the gear pump, the T port is the oil return port of the valve block, the TT port is the oil return port of the pressure compensation valve 1, the A port is connected to the oil inlet port of the vibration motor, and the B port is connected to the oil outlet port of the vibration motor.

[0024] The A1 port (the first oil outlet) of the three-position four-way proportional valve 2 is connected to the A port, the B1 port (the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com