Control device and control method of thermal power plant

A thermal power plant and control device technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as changing control algorithms, and achieve the effect of suppressing the deterioration of characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

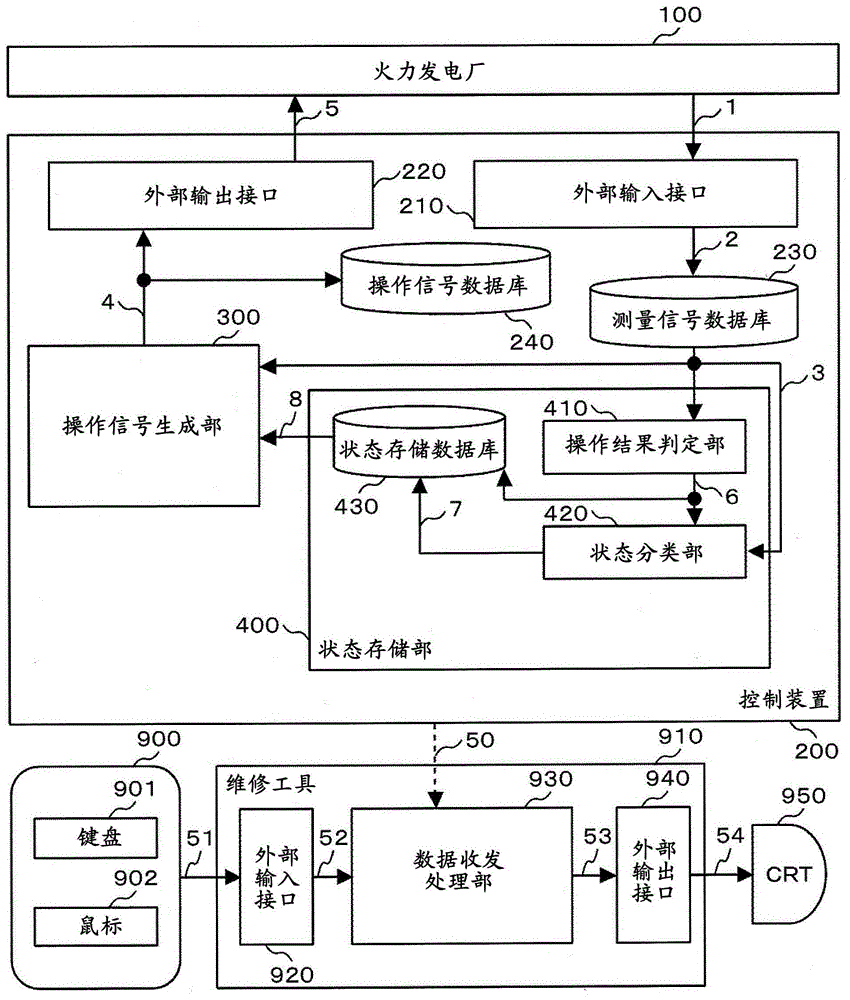

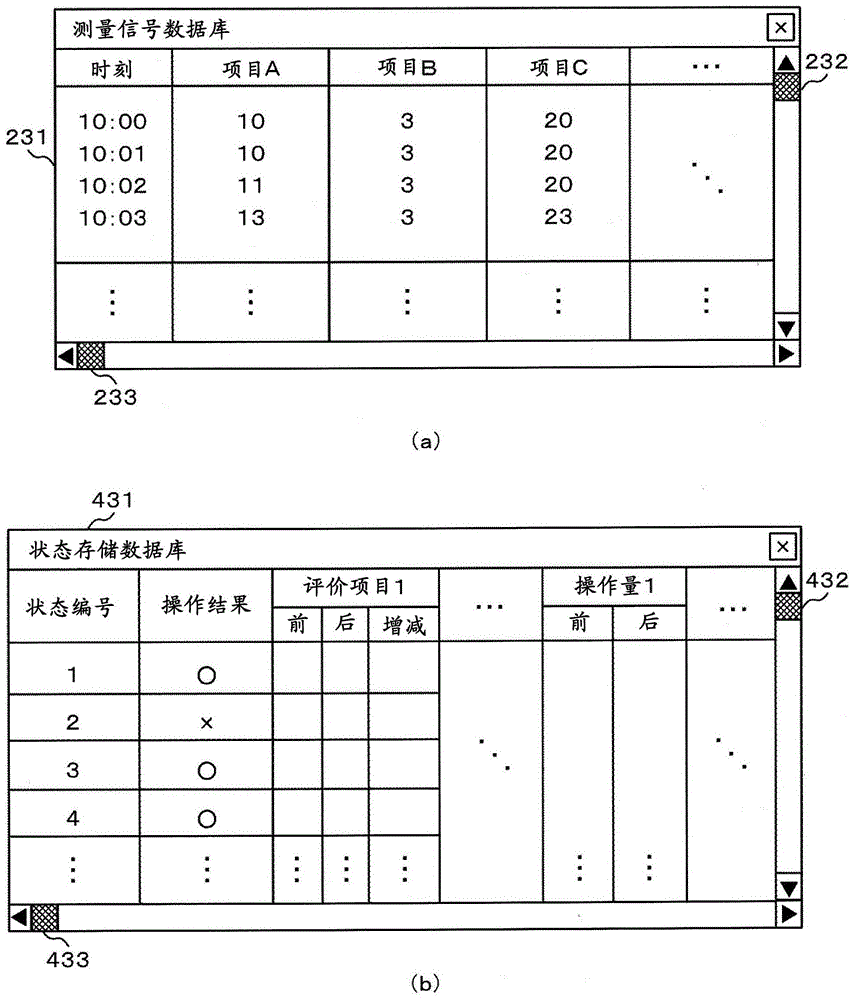

[0029] figure 1 It is a block diagram of the first embodiment of the control device of the thermal power plant. The control device 200 controls the thermal power plant 100 as a control object.

[0030] The control device 200 has an operation signal generation unit 300 , an operation result determination unit 410 , and a state classification unit 420 . The control device 200 has a measurement signal database 230 , an operation signal database 240 , and a state storage database 430 as databases. In addition, in this embodiment, the operation result determination unit 410 , the status classification unit 420 , and the status storage database 430 are collectively referred to as the status storage unit 400 .

[0031] In addition, the control device 200 has an external input interface 210 and an external output interface 220 as interfaces with the outside. The control device 200 inputs the measurement signal 1 from the thermal power plant 100 to the control device 200 via the ext...

Embodiment 2

[0148] Figure 9 It is a configuration diagram of the second embodiment of the control device 200 of the thermal power plant 100 . The control device 200 of the thermal power plant 100 of the present embodiment has a configuration in which an operation method learning unit 500 is added to the control device 200 of the thermal power plant 100 of the first embodiment.

[0149] The operation method learning unit 500 is constituted by a model 520 , an evaluation value calculation unit 530 , a calculation unit of the learning unit 540 , a model database 510 , and a database of learning information database 550 .

[0150] In the operation method learning unit 500 , the learning information database information 16 is obtained by referring to the measurement signal 3 .

[0151] The learning information database information 16 stored in the learning information database 550 is generated by the model 520 , the evaluation value calculation unit 530 , and the learning unit 540 .

[0152...

Embodiment 3

[0171] Figure 12 It is a block diagram of the third embodiment of the control device of the thermal power plant. The control device 200 of the thermal power plant 100 of the present embodiment is configured by adding a feature extraction unit 440 to the state storage unit 400 of the control device 200 of the thermal power plant 100 of the second embodiment.

[0172] The feature extraction unit 440 compares the result of the operation and the improvement and deterioration of the characteristics of the thermal power plant 100 to extract data items of the operation signal 5 that generate characteristic differences in the state of the thermal power plant 100 . Model accuracy is improved by adding the extracted data items to the model input items of the model 520 .

[0173] Figure 13 It is a figure explaining the operation|movement of the control apparatus 200 of this Example.

[0174] Figure 13 (a) is a diagram explaining the operation of the feature extraction unit 440 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com