Method of manufacture of group iii nitride semiconductor

A technology of nitride semiconductor and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, manufacturing tools, etc., can solve the problem of high cost, and achieve the effect of suppressing the deterioration of characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

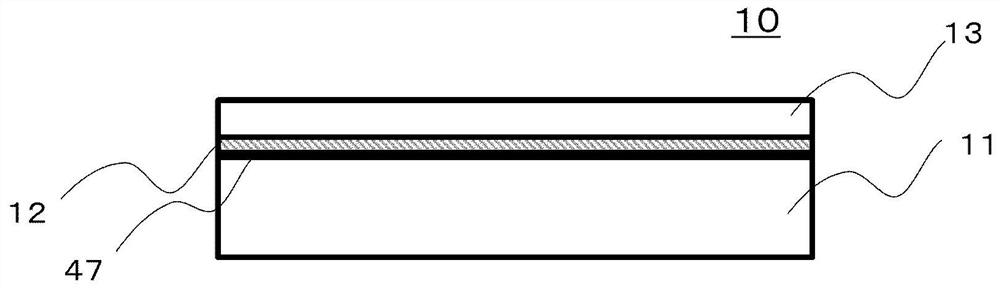

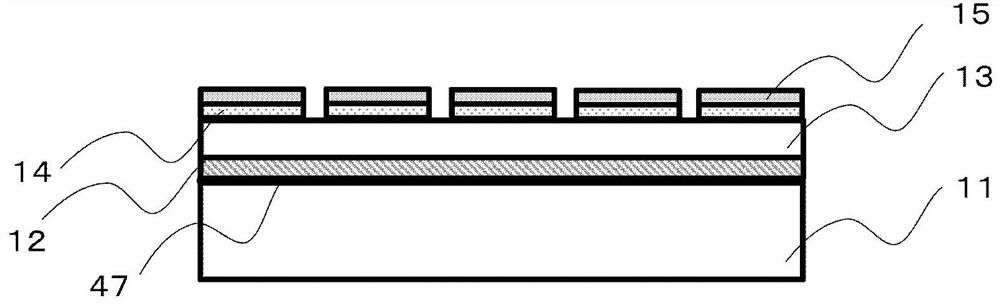

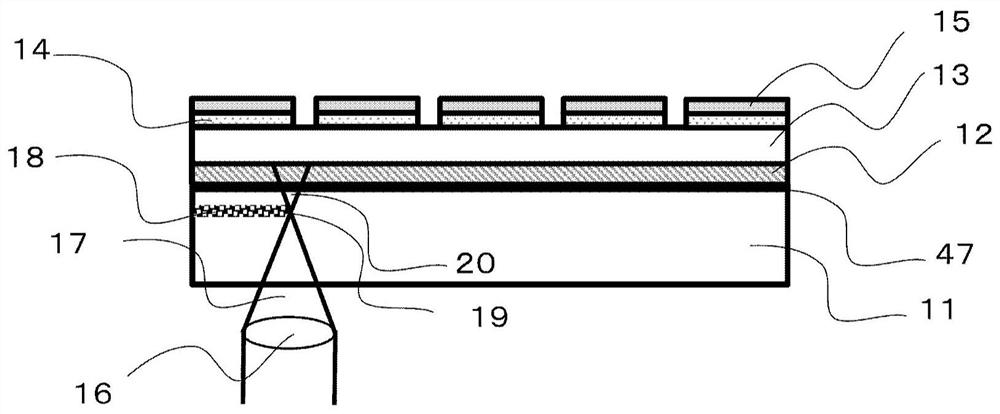

[0118] Figure 1-1 to Figure 1-4 It is a schematic cross-sectional view showing each step of the method for manufacturing a group III nitride semiconductor described in Embodiment 1.

[0119]The method for manufacturing a group III nitride semiconductor described in Embodiment Mode 1 includes the step of preparing to stack the first group III nitride layer 11 , the second group III nitride layer 12 , and the third group III nitride layer sequentially from the back side to the front side. The process ( Picture 1-1 ); a step of forming a device structure on the surface side of a group III nitride substrate ( Figure 1-2 ); and a step of dividing the III-nitride substrate by irradiating laser light from the first III-nitride layer on the back side of the III-nitride substrate ( Figure 1-3 with Figure 1-4 ). The first group III nitride layer 11 has a transmittance of 60% or more with respect to a predetermined wavelength of 400 nm to 700 nm. The second III-nitride layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com