An isolating grounding switch

A technology of isolating grounding switch and grounding switch, which is applied in switchgear, switchgear setting, electrical components, etc., can solve the problems of reducing the isolation grounding switch, the inability of both sides of the disconnection switch to be grounded at the same time, and the large volume of the isolating grounding switch. Achieve the effect of volume reduction, easy grounding, stable and reliable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

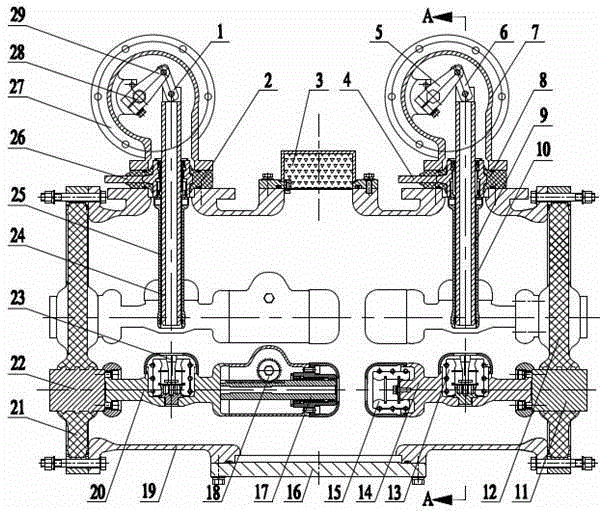

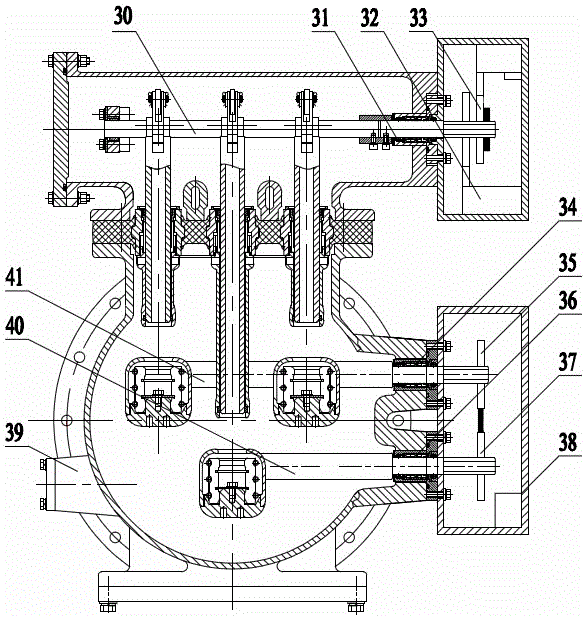

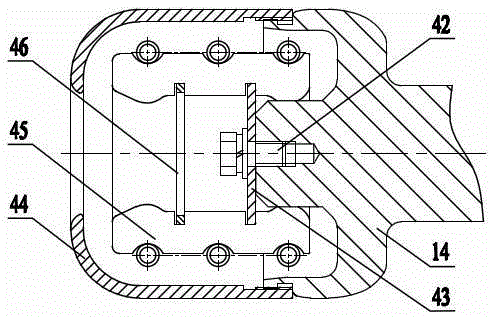

[0027] Embodiment 1: as Figure 1-3 As shown, an isolating grounding switch includes three parts: isolating switch, grounding switch I, and grounding switch II, specifically including connecting rod I1, insulating basin I2, desiccant 3, grounding terminal II4, crank arm II5, connecting rod II6, Grounding shell II7, insulating basin II8, earthing switch movable contact II9, earthing switch movable contact shield II10, body insert I11, disc insulator I12, earthing switch static contact II13, static side conductor 14, isolating switch static contact Head 15, cover plate 16, rack moving contact rod 17, gear 18, metal shell 19, moving side conductor 20, disc insulator II21, body insert II22, grounding switch static contact I23, earthing switch moving contact I24, Earthing switch moving contact shield cover Ⅰ25, grounding terminal Ⅰ26, grounding shell Ⅰ27, transmission shaft Ⅰ28, crank arm Ⅰ29, transmission shaft Ⅱ30, shaft seal Ⅰ31, operating mechanism box Ⅰ32, locking lever Ⅰ33, s...

Embodiment 2

[0035] Embodiment 2: as Figure 1-3As shown, an isolating grounding switch includes three parts: isolating switch, grounding switch I, and grounding switch II, specifically including connecting rod I1, insulating basin I2, desiccant 3, grounding terminal II4, crank arm II5, connecting rod II6, Grounding shell II7, insulating basin II8, earthing switch movable contact II9, earthing switch movable contact shield II10, body insert I11, disc insulator I12, earthing switch static contact II13, static side conductor 14, isolating switch static contact Head 15, cover plate 16, rack moving contact rod 17, gear 18, metal shell 19, moving side conductor 20, disc insulator II21, body insert II22, grounding switch static contact I23, earthing switch moving contact I24, Earthing switch moving contact shield cover Ⅰ25, grounding terminal Ⅰ26, grounding shell Ⅰ27, transmission shaft Ⅰ28, crank arm Ⅰ29, transmission shaft Ⅱ30, shaft seal Ⅰ31, operating mechanism box Ⅰ32, locking lever Ⅰ33, sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com