Heating ring with diameter capable of being adjusted in fine mode

A technology of heating ring and fine-tuning mechanism, which is applied in the field of heating ring, and can solve problems such as cracking of the heating ring, unfavorable operation, and a large number of handles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

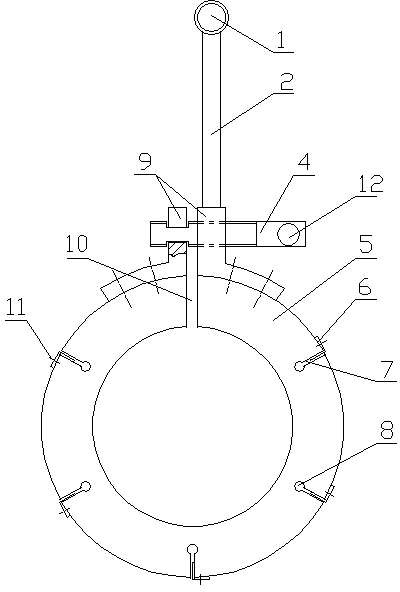

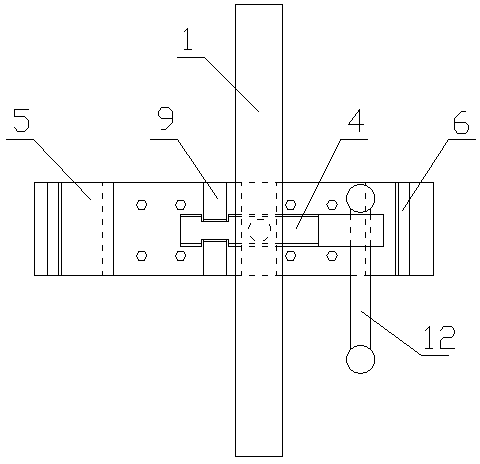

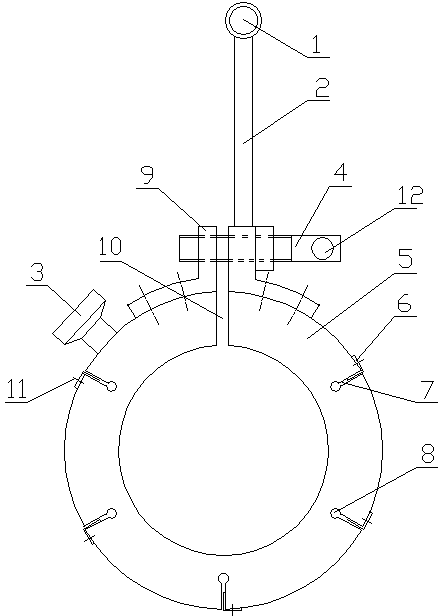

[0020] Referring to the accompanying drawings, the heating ring whose diameter can be finely adjusted includes a heating ring body 5, and the heating ring is made of copper material, which has the characteristics of low hardness and large heat capacity. The heating ring body 5 has an opening slit 10, and the outer peripheral surface of the heating ring body 5 is provided with an expansion joint 7 that is consistent with the axial width of the heating ring body 5. The expansion joint 7 is evenly distributed along the radial sides of the opening slit 10. The number is generally 5 or 7, and one of the expansion joints 7 is set opposite to the opening joint 10 . In order to prevent the root of the expansion joint from breaking due to stress concentration under repeated tension and compression, an anti-crack hole 8 is provided at the root of the expansion joint 7. The anti-crack hole 8 and the root of the expansion joint 7 have a circular arc transition, and the inner diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com