Preparation method of polymer nano-fiber with uniform diameter

A nanofiber and polymer technology, applied in the direction of single-component synthetic polymer rayon, spinning solution preparation, fiber chemical characteristics, etc., can solve the problem of wide distribution of nanofiber diameter, difficulty in preparing fibers, unfavorable environmental sustainable development, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a) 20 grams of polystyrene and poly(4-vinylpyridine) copolymer (poly(4-vinylpyridine) accounts for 9% of the total volume of the copolymer, and the total molecular weight is 40,000 daltons) placed in In the reaction vessel, add 80 grams of acetic acid in the reaction vessel again;

[0023] b) Heating the reaction vessel containing the mixture to 110° C. and maintaining it for 15 hrs to obtain polymer nanofibers uniformly dispersed in acetic acid.

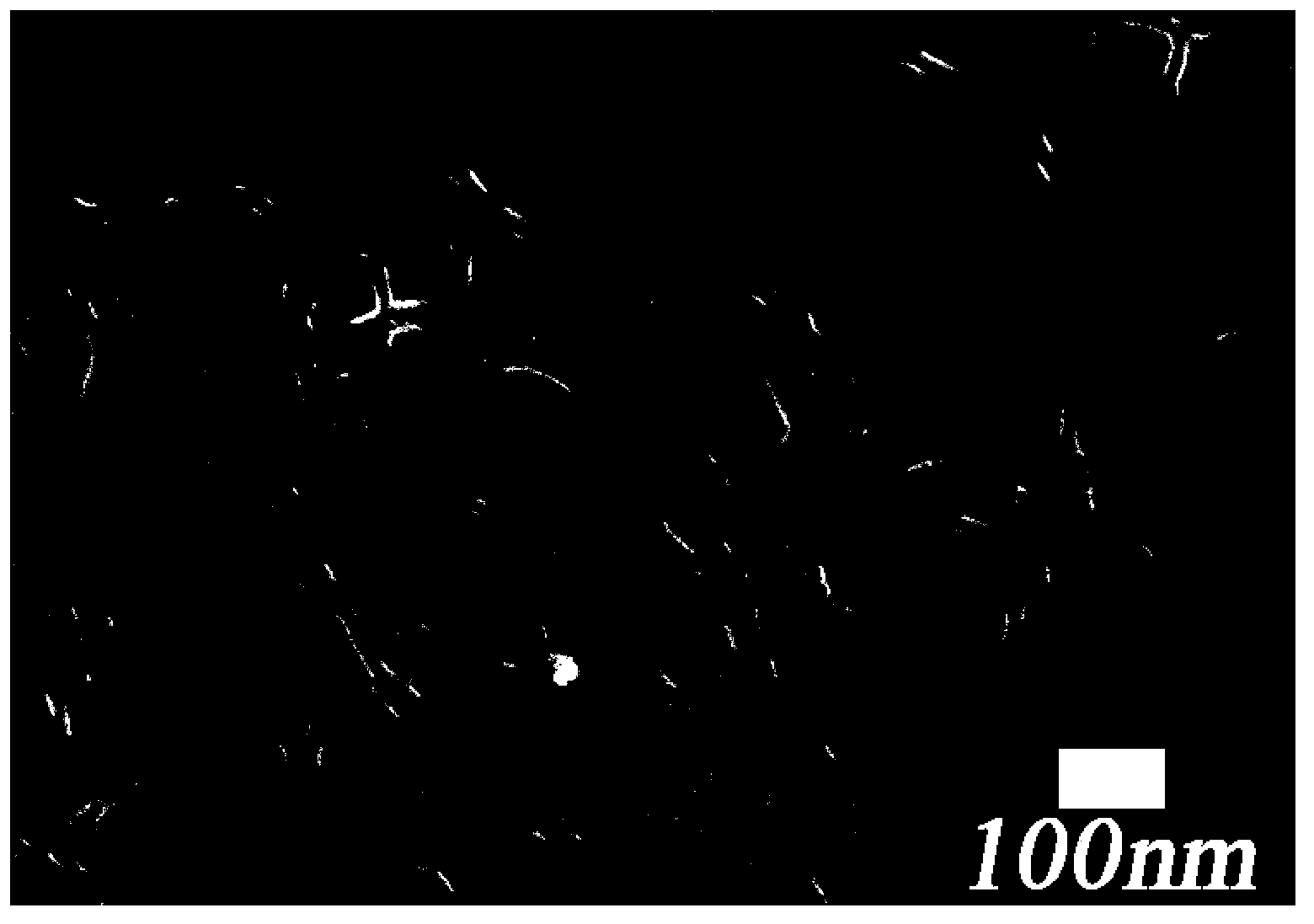

[0024] Depend on figure 1 It can be seen that the polymer nanofibers prepared in Example 1 have a uniform diameter, and the fiber diameter measured from the SEM image is 30 nm.

[0025] The prepared polymer nanofibers were put into ethanol solution, and the polymer nanofibers remained unchanged for 4 months.

Embodiment 2

[0027] a) Place 0.2 g of a copolymer of polystyrene and poly(4-vinylpyridine) (poly(4-vinylpyridine) accounts for 13% of the total volume of the copolymer, and the total molecular weight is 10,000 daltons) in In the reaction vessel, add 99.8 grams of a mixed solvent of ethanol and acetic acid (the mass ratio of ethanol to acetic acid is 4:1);

[0028] b) Heating the reaction vessel containing the mixture to 70° C. and keeping it for 5 hrs to obtain polymer nanofibers uniformly dispersed in the mixed solvent.

[0029] Depend on figure 2 It can be seen that the polymer nanofibers prepared in Example 2 have a uniform diameter, and the fiber diameter measured from the SEM image is 27 nm.

[0030] The prepared polymer nanofibers were put into ethanol solution, and the polymer nanofibers remained unchanged for 6 months.

Embodiment 3

[0032] a) Place 1 gram of polystyrene and poly(2-vinylpyridine) copolymer (poly(2-vinylpyridine) accounts for 25% of the total volume of the copolymer, and the total molecular weight is 50,000 Daltons) in In the reaction vessel, add 99 grams of acetic acid in the reaction vessel again;

[0033] b) Heating the reaction vessel containing the mixture to 120° C. and maintaining it for 24 hrs to obtain polymer nanofibers uniformly dispersed in acetic acid.

[0034] The polymer nanofibers prepared in this example have a uniform diameter, and the measured fiber diameter is 40 nm. Put it in ethanol solution and leave it for 6 months without any change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com