Liquid spraying device for wiper blades

A technology of spraying device and wiper, which is applied in the field of window equipment and vehicle equipment, can solve the problems of no detailed description of the way of setting the spraying device layout, no industrial-scale solution showing the economic needs of the automotive field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

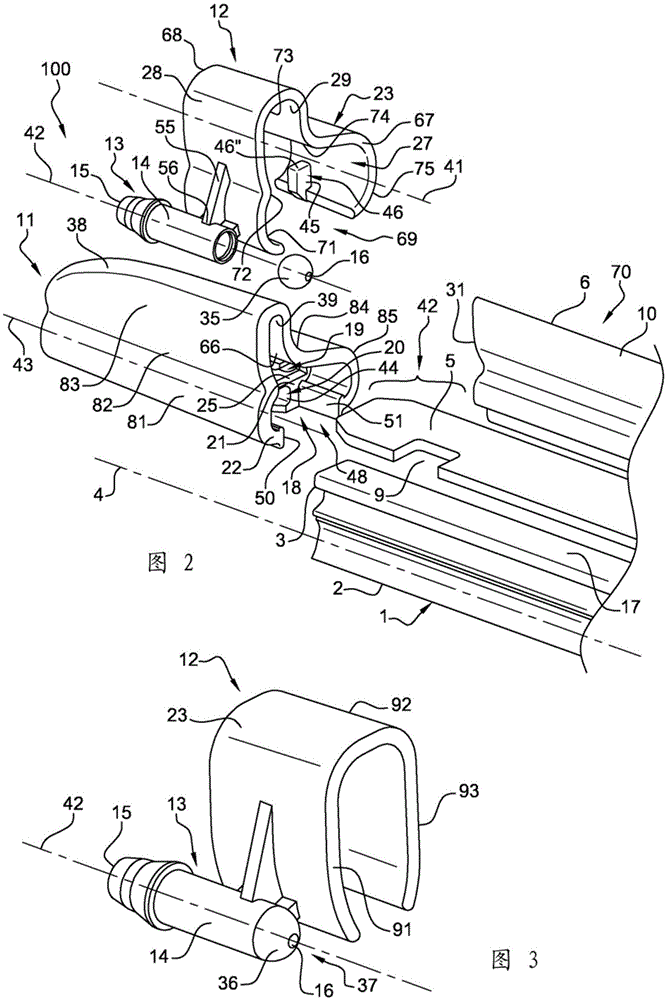

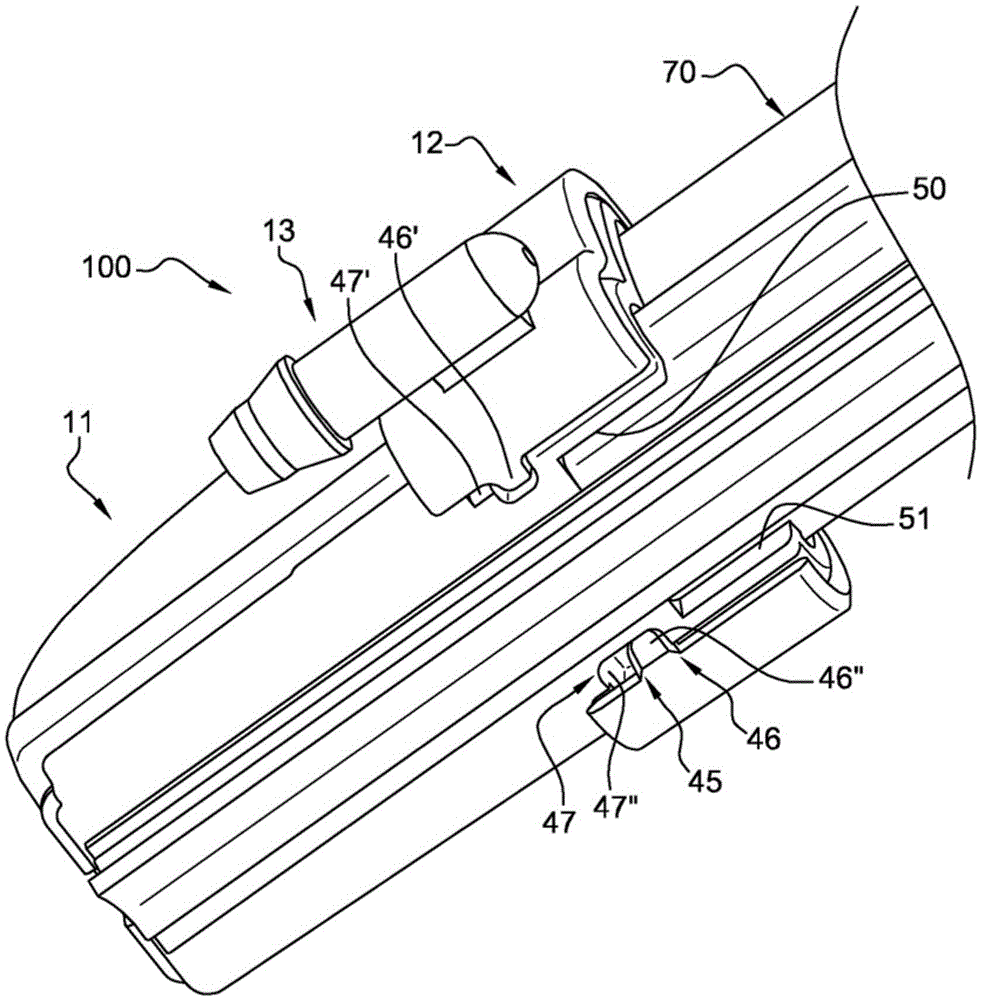

[0030] It should be noted that the drawings disclose the invention in a detailed manner in order to carry it out and that said drawings can of course be used to define the invention more clearly, where necessary.

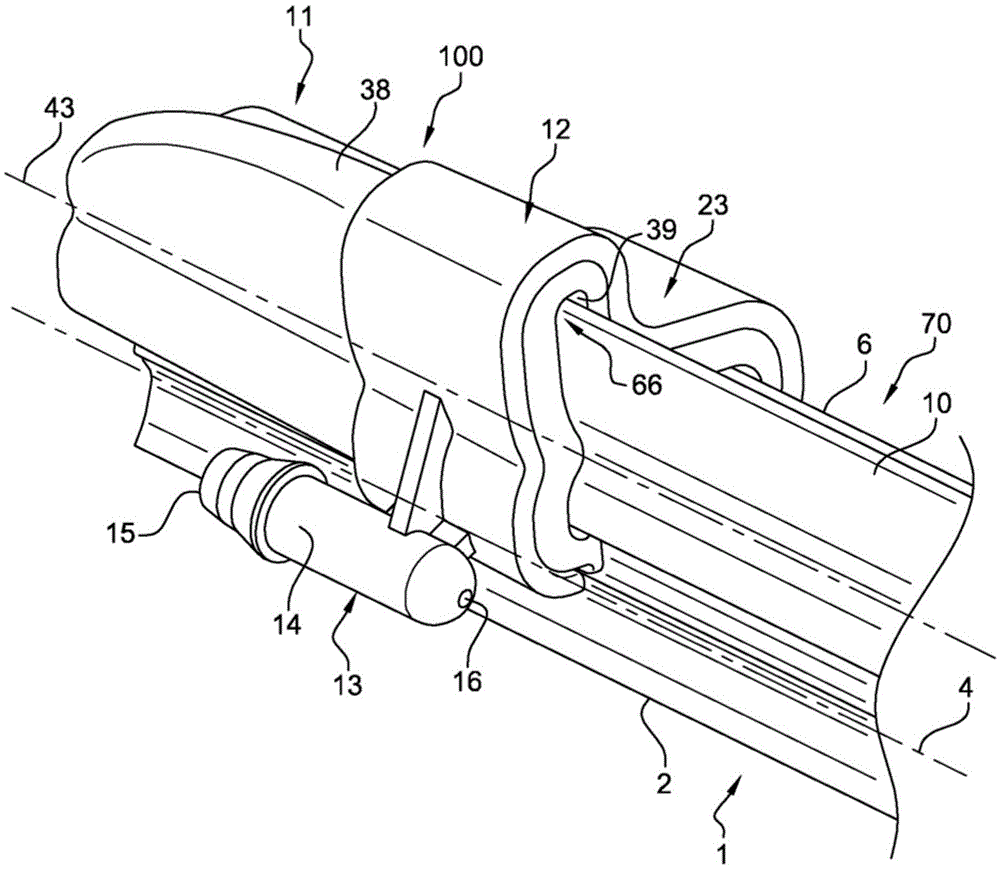

[0031] figure 1 A wiper 70 is shown in a partial manner, with which a wiping system mounted on a motor vehicle is provided. The wiper 70 is mounted on the front windshield of the vehicle, but it may also be mounted on the rear window of the vehicle.

[0032] The wiper comprises a wiper blade 1 , also called wiper blade, comprising an area 2 for rubbing on the window, said area being connected to the heel by a thinning. The heel provides a mechanical connection to the constituent support of the wiper. The wiper blade 1 extends longitudinally along a longitudinal axis 4 .

[0033] The wiper 70 further comprises a ridge (in figure 2 ), the ridges form reinforcements for the wiper 70. By way of example, this is a single metal strip which extends along the longitud...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap