A new process of multi-stage planting defluoridation water treatment based on pre-reverse osmosis technology

A reverse osmosis and water treatment technology, applied in the field of water treatment technology, can solve the problems of excessive aluminum ions, large floor area, and reduced defluoridation effect, and achieve the effect of prolonging the service life and improving the treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

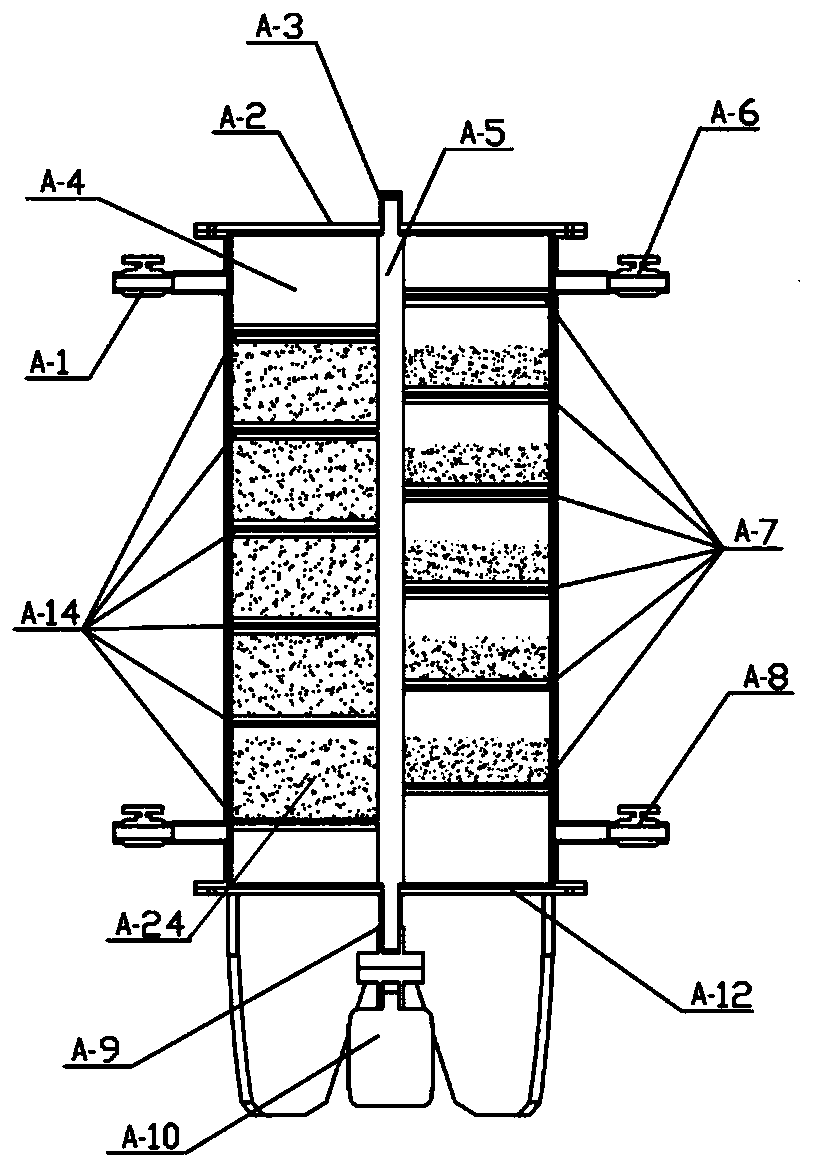

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

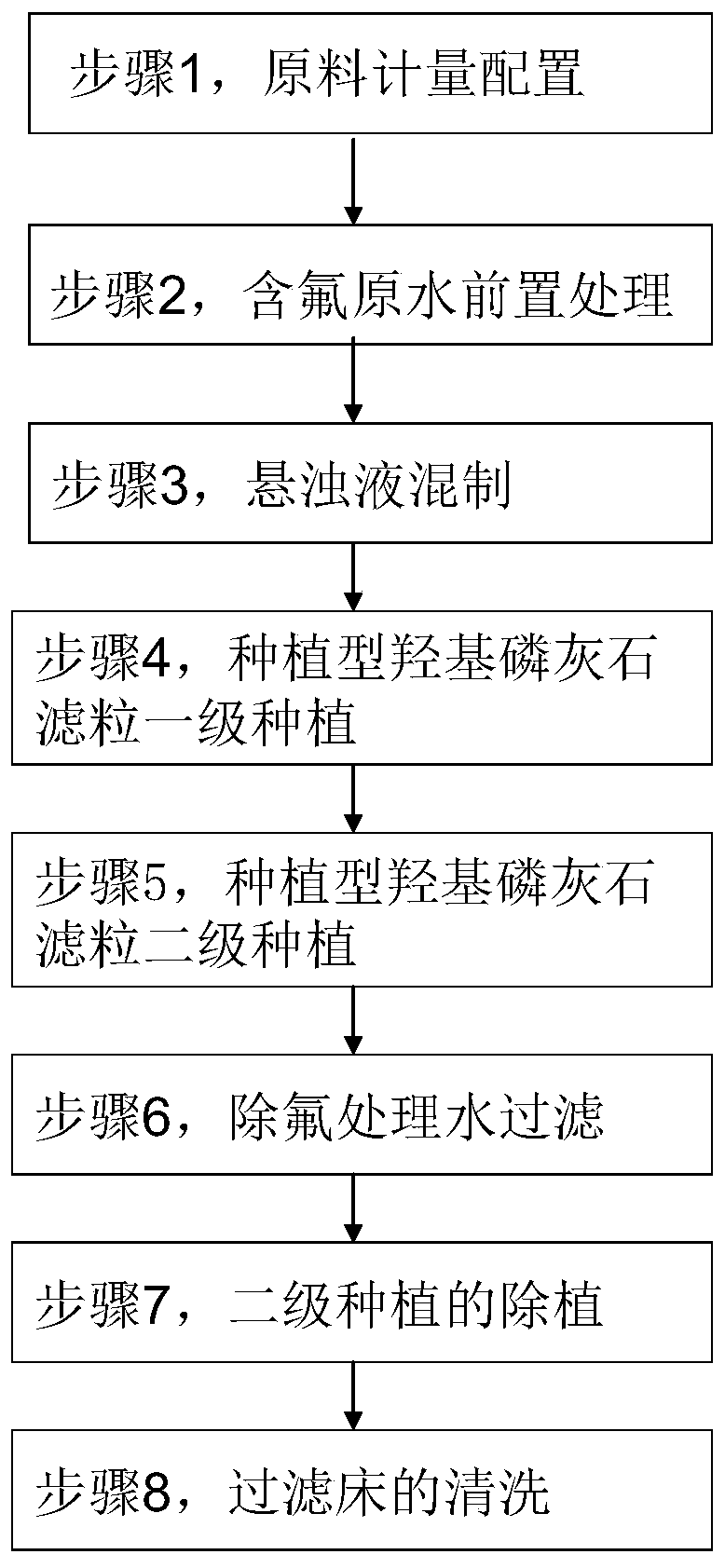

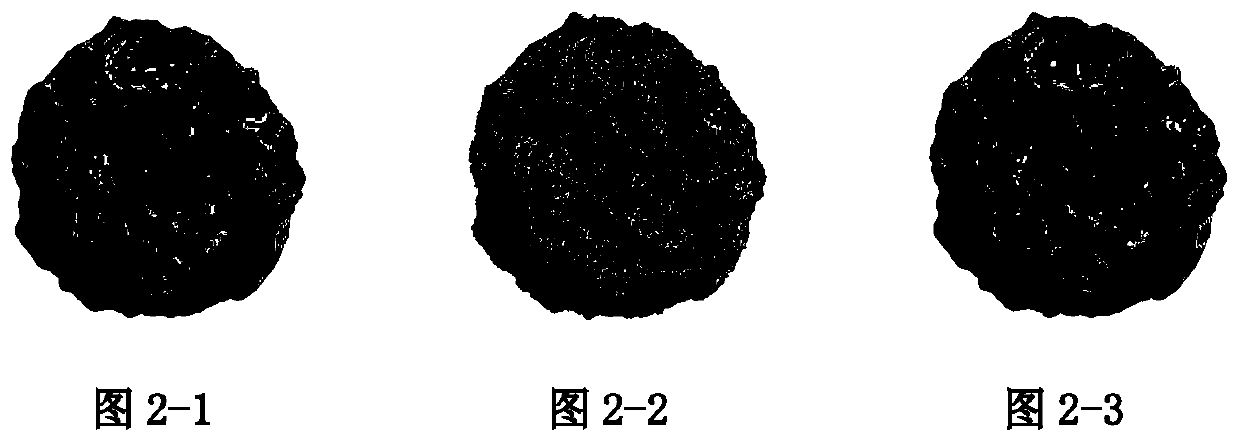

[0032] combine figure 1 with figure 2 , a new process of multi-stage planting defluoridation water treatment based on pre-reverse osmosis technology proposed by the present invention, using fluorine-containing raw water, water treatment agent and planting hydroxyapatite filter particles as starting materials, after fluorine-containing Raw water pre-treatment, suspension mixing, primary planting of planting hydroxyapatite filter particles, secondary planting of planting hydroxyapatite filter particles, and defluoridation treated water filtration, to obtain treated defluoridated water, Its concrete steps include as follows:

[0033] Step 1, raw material metering configuration: starting raw materials include fluorine-containing raw water, calcium brine treatment agent and phosphate brine treatment agent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com