Colloidal Inert Foam Preparation Device for Preventing Coal Spontaneous Combustion and Its Process

A preparation device and coal spontaneous combustion technology, which is applied in the direction of safety devices, dust prevention, mining equipment, etc., can solve the problem of high-level space fires in long-distance gobs that cannot be fully effective, fire prevention and extinguishing materials that are difficult to fill in large areas, and coal spontaneous combustion fire effects Unsatisfactory problems, to achieve the effect of preventing the oxidation and heat release of coal, the effect of fire prevention and extinguishing is remarkable, and the effect of inhibiting spontaneous combustion of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

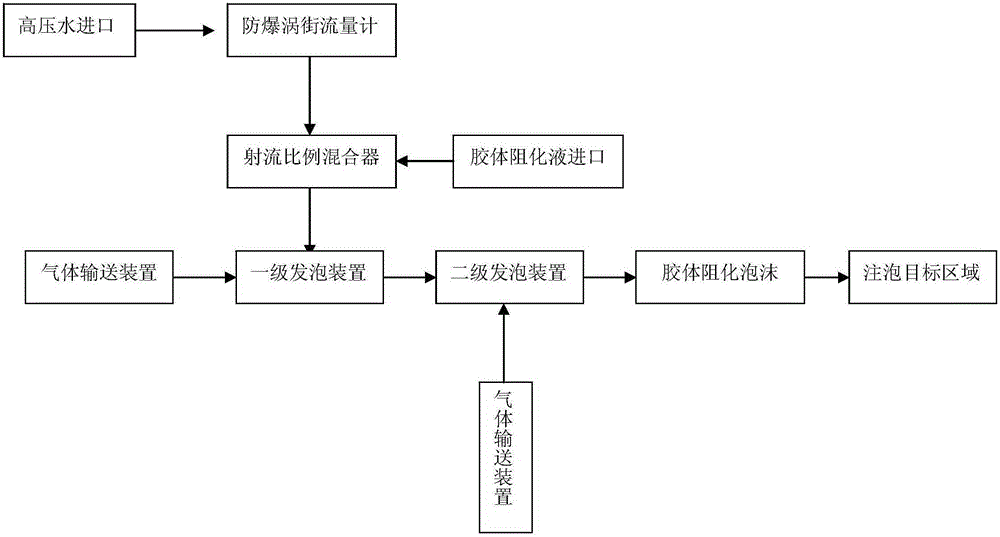

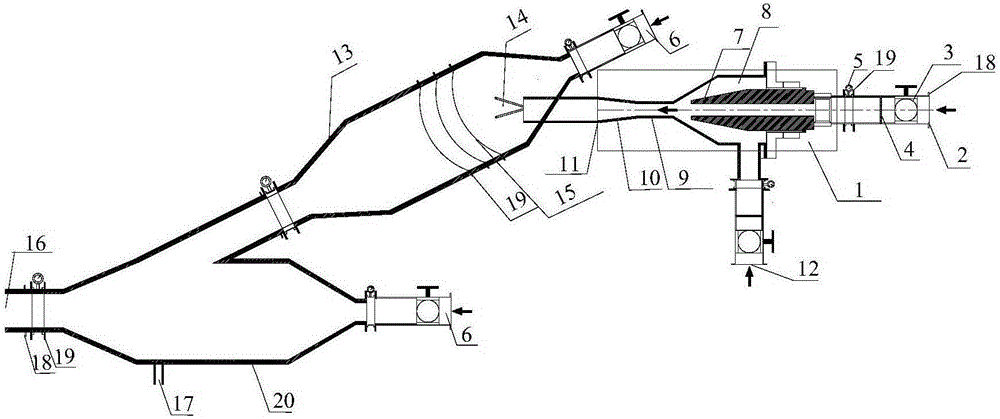

[0031] see figure 1 , figure 2 , The colloid retardation inert foam preparation device of the present invention includes a jet proportional mixer device, a primary foaming device, a secondary foaming device and a gas delivery device. The jet proportional mixer device includes a jet proportional mixer 1, a pressure water inlet 2 connected to the jet proportionalor nozzle 7, a colloidal resistance fluid inlet 12 connected to the jet proportionalor suction chamber 8, a jet proportionalator output port 11 and a The first-stage foaming device is connected to the liquid inlet; the first-stage foaming device includes a foaming chamber placed in the shell, and a spiral nozzle 14 connected to the liquid inlet. The foaming chamber is provided with a foaming net 15, and the colloid resistance of the foaming chamber The inert bubble output port is connected with the colloid resistance inert bubble inlet of the secondary foaming device, and the air inlet 6 of the foaming device is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com