Method for correcting deformation of welding part of nozzle casting

A technology for welding parts and castings, which is applied in the field of deformation correction of investment precision castings, can solve problems such as difficult to determine the heating range, difficult correction, difficult correction, etc., to achieve rapid detection, meet product quality requirements, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Nozzle Housing

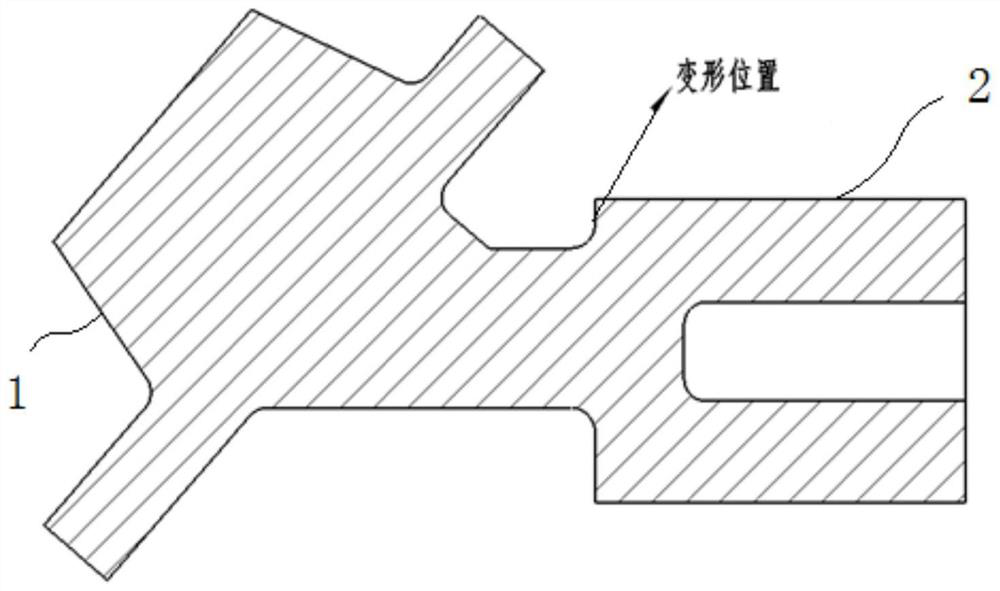

[0046] 1) The nozzle shell is welded to the repair welding casting 2, and a deformed position is formed at the welding place. The appearance of the repair welding casting 2 of the nozzle shell is polished to make the repair welding part smooth and flat.

[0047] 2) Mark the size of the center of the hole on the deformed part, and compare it with the standard qualified parts. Determine the deformation position and deformation amount of the welded part according to the line spacing, and expand the deformation range to 5mm a week for contour marking.

[0048] 3) Install the marked repair welding casting 2 on the correction tooling, and the parts to be corrected are completely exposed. To ensure the level of the casting, fasten the welding parts on the correction tooling.

[0049] 4) Open the acetylene-oxygen device (heating gun), use the flame core to heat in the marked range, use an infrared temperature measuring device to detect the heating temperature, tu...

Embodiment 2

[0054] mouth

[0055] 1) The nozzle and the repair welding casting 2 are welded and connected to form a deformed position at the welding point, and the repair welding casting 2 of the butt nozzle is ground to make the repair welding part smooth and clean.

[0056] 2) Mark the center size of the deformation position and compare it with the standard qualified parts. According to the line spacing, the deformation position and deformation amount of the welded parts are clarified, and the deformation range is expanded by about 5mm for contour marking.

[0057] 3) The marked repair welding casting 2 is installed on the correction tooling, so that the parts to be corrected are completely exposed and unobstructed. When the casting is in a horizontal state, fasten the welding parts on the correction tooling.

[0058] 4) Open the acetylene-oxygen device (heating gun), use the flame core to heat in the marked range, use an infrared temperature measuring device to detect the heating tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com